Ferrous ion reduction and catalytic oxidation cooperation for reinforcing waste water biological treatment technology

A technology of catalytic oxidation and biological treatment, applied in the direction of reducing water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. Reduction of pollutants is not obvious and other problems, to achieve the effect of improving wastewater biological treatment effect, improving catalytic oxidation efficiency, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Taking the treatment of printing and dyeing wastewater as an example, the implementation steps are further explained.

[0027] Step 1: Weigh 27.8g of FeSO 4 ·7H 2 O dissolve it in 100mL of water without dissolved oxygen, gradually add 5mol / L anaerobic sodium hydroxide solution to the above solution, stir while adding, the molar ratio of ferrous ion and hydroxide is 0.58, and generate FHC .

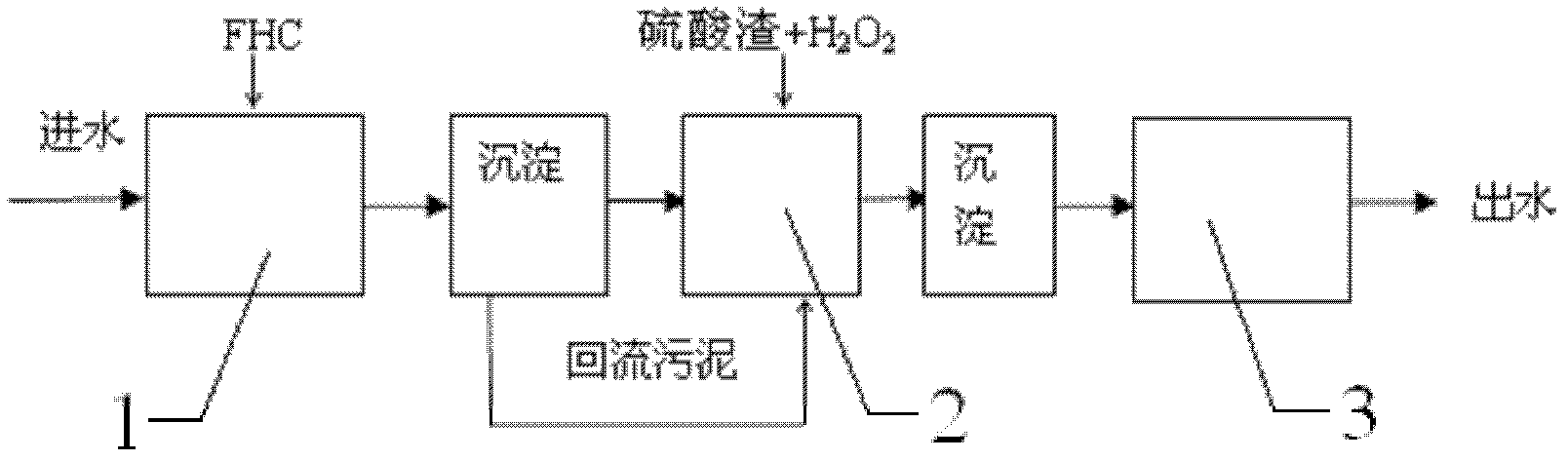

[0028] Step 2: Take 20L of actual printing and dyeing wastewater and put it into a reactor (referred to as reactor A). Add the FHC solution that has been prepared in reactor A, make Fe 2+ The content is about 50 mg / L, and after stirring for 20 minutes, it precipitates, and the supernatant is transferred to a Fenton-like oxidation pool (referred to as reactor B).

[0029] Step 3: add sulfuric acid slag (dosing ratio: 10mg / L) and hydrogen peroxide (dosing ratio: 0.01ml / L) to reactor B, and return the sludge in reactor A to reactor B , the reflux ratio is 1% (the ratio of the volu...

Embodiment 2

[0032] Treatment of printing and dyeing wastewater

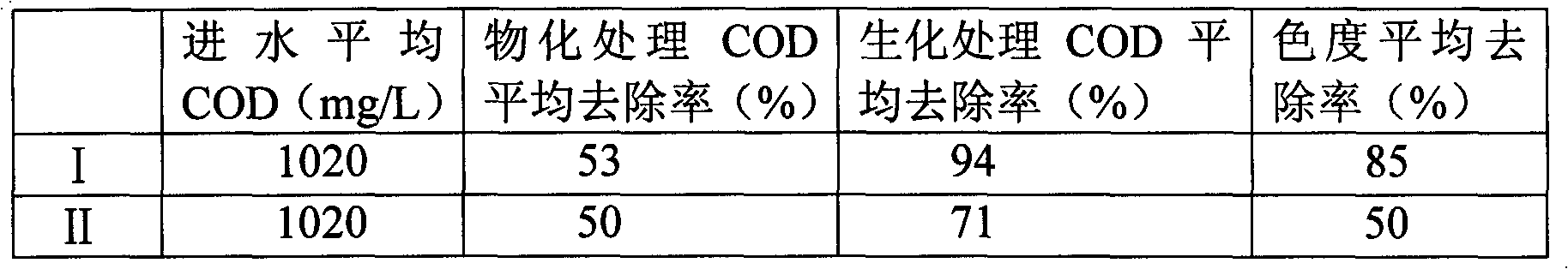

[0033] I: Synergistic enhancement of ferrous reduction and catalytic oxidation for wastewater biological treatment

[0034] Step 1: Take 27.8g of FeSO 4 ·7H 2O dissolve it in 100mL of water without dissolved oxygen, gradually add 5mol / L anaerobic sodium hydroxide solution to the above solution, stir while adding, the molar ratio of ferrous ion and hydroxide is 0.8, and generate FHC .

[0035] Step 2: Take 25L of actual printing and dyeing wastewater and put it into reactor A, add the prepared FHC solution to make Fe 2+ The mass concentration is 100mg / L. Stir the reaction for 60 minutes, precipitate for 30 minutes, and transfer the supernatant to reactor B.

[0036] The third step: add sulfuric acid slag (dosing ratio is 50mg / L) and hydrogen peroxide (dosing ratio is 0.1ml / L) in reactor B, and return the sludge in reactor A to reactor B, The reflux ratio was 2%, the reaction was stirred for 60 minutes, and the precipita...

Embodiment 3

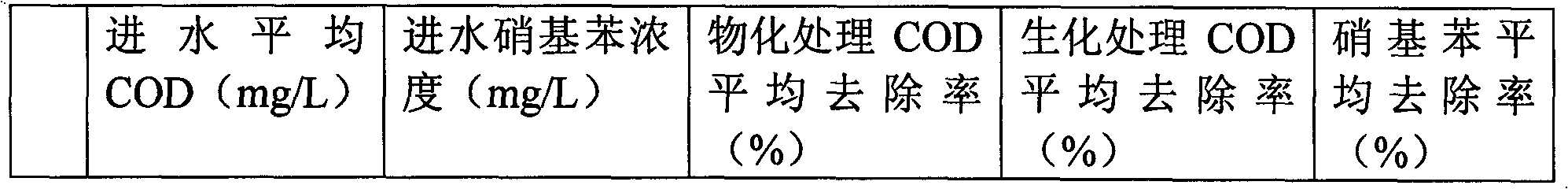

[0043] Treatment of Mixed Wastewater of Nitrobenzene Wastewater and Printing and Dyeing Wastewater

[0044] I: Synergistic enhancement of ferrous reduction and catalytic oxidation for wastewater biological treatment

[0045] The first step: take 12.7g of FeCl 2 Dissolve it in 100mL of water without dissolved oxygen, gradually add 5mol / L anaerobic sodium hydroxide solution to the above solution, stir while adding, the molar ratio of ferrous ion and hydroxide is 0.3, and generate FHC.

[0046] Step 2: Take 25L of mixed waste water and put it into reactor A, add FHC solution to make Fe 2+ The mass concentration is 200mg / L. Stir the reaction for 40 minutes, precipitate for 20 minutes, and transfer the supernatant to reactor B.

[0047] The third step: add sulfuric acid slag (dosing ratio is 50mg / L) and hydrogen peroxide (dosing ratio is 0.1ml / L) in reactor B, and return the sludge in reactor A to reactor B, The reflux ratio was 3%, the reaction was stirred for 120 minutes, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com