Sustained and controlled release composite fertilizer and preparation method thereof

A compound fertilizer and fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of shortening the release time of chemical fertilizers, affecting the growth of crops, and high production costs, achieving good drought resistance and water retention, long nutrient release time, and chemical fertilizers. High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

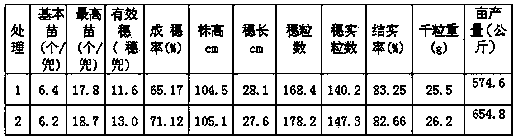

Examples

Embodiment 1

[0029] A slow-release compound fertilizer, characterized in that it is composed of the following raw materials by weight: 30% nitrogen fertilizer, 16.2% phosphate fertilizer, 14.2% potassium fertilizer, 3.5% fertilizer nutrient fixative, and citric acid-soluble phosphorus containing 20% phosphorus pentoxide. Ore powder 18%, citric acid-soluble potassium feldspar powder containing 10% potassium oxide 18%, phosphate-solubilizing potassium-solubilizing bacteria 0.1%.

[0030] The proportion of each component in the fertilizer nutrient fixative is: sepiolite 85.5%, polyaluminum ferric chloride 12.9%, chitosan 1.6%

[0031] A preparation method of slow and controlled release compound fertilizer, comprising the following steps:

[0032] 1) To make fertilizer nutrient fixative: fully mix sepiolite, polyaluminum ferric chloride and chitosan according to the proportion, and pulverize to 80 mesh;

[0033] 2) Transport NPK fertilizer, fertilizer nutrient fixative, citric acid soluble ...

Embodiment 2

[0037] A slow-release compound fertilizer, characterized in that it is composed of the following raw materials by weight: 32% nitrogen fertilizer, 16% phosphate fertilizer, 14% potassium fertilizer, 3% fertilizer nutrient fixative, and citric acid-soluble phosphorus containing 25% phosphorus pentoxide. Ore powder 13.6%, citric acid-soluble potassium feldspar powder containing 15% potassium oxide 21.3%, phosphate-solubilizing potassium-solubilizing bacteria 0.1%.

[0038] The proportion of each component in the fertilizer nutrient fixative is: sepiolite 97.7%, polyaluminum ferric chloride 1.9%, chitosan 0.4%

[0039] A preparation method of slow and controlled release compound fertilizer, comprising the following steps:

[0040] 1) To make fertilizer nutrient fixative: fully mix sepiolite, polyaluminum ferric chloride and chitosan according to the proportion, and pulverize to 160 mesh;

[0041] 2) Transport NPK fertilizer, fertilizer nutrient fixative, citric acid soluble phos...

Embodiment 3

[0045] A slow-release compound fertilizer, characterized in that it is composed of the following raw materials by weight: 31% of nitrogen fertilizer, 16.5% of phosphate fertilizer, 14.5% of potassium fertilizer, 3.88% of fertilizer nutrient fixative, and citric acid-soluble phosphorus containing 22% of phosphorus pentoxide. Ore powder 14.05%, citric acid-soluble potassium feldspar powder containing 14% potassium oxide 20%, phosphate-solubilizing potassium-solubilizing bacteria 0.15%.

[0046] The proportion of each component in the fertilizer nutrient fixative is: sepiolite 89%, polyaluminum ferric chloride 9.1%, chitosan 1.9%

[0047] A preparation method of slow and controlled release compound fertilizer, comprising the following steps:

[0048] A preparation method of slow and controlled release compound fertilizer, comprising the following steps:

[0049] 1) To make fertilizer nutrient fixative: fully mix sepiolite, polyaluminum ferric chloride and chitosan according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com