Preparation method of silicon dioxide microsphere/polyformaldehyde composite material

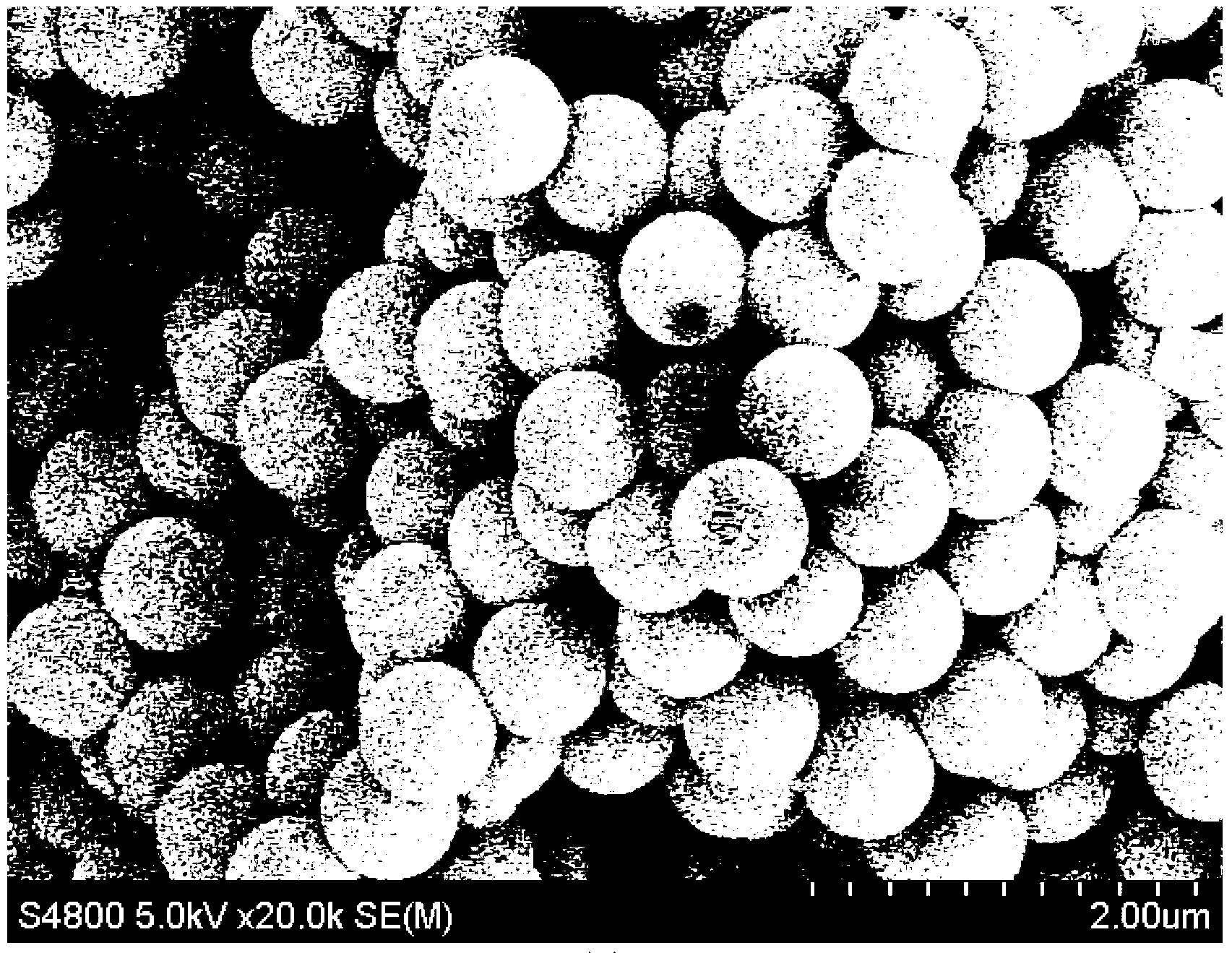

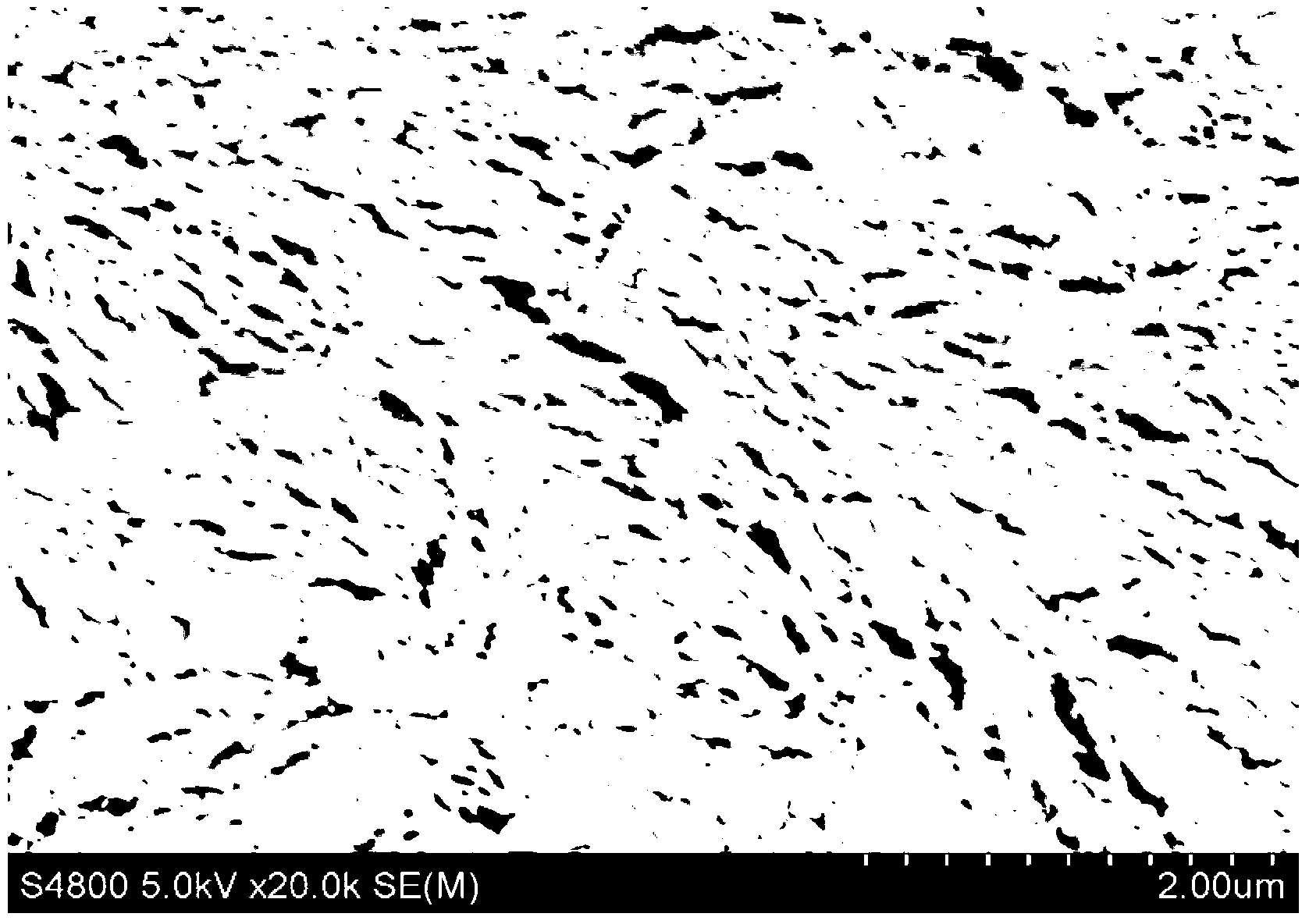

A technology of silicon dioxide microspheres and composite materials, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of low impact strength, low impact strength and bending strength, and achieve good impact strength, controllable size and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of a kind of silicon dioxide microsphere / polyoxymethylene composite material of this embodiment is carried out according to the following steps:

[0015] 1. Synthesis of monodisperse silica spheres: a. Add ammonia water and ethanol with a mass percentage of 25% to a three-neck flask, then add silica seed solution, and stir evenly at 220 rpm; b. Keep 25 ℃ constant temperature water bath and 220rpm stirring speed, drop mixed solution A and mixed solution B at the same time, wherein the dropping rate of mixed solution A is 0.10mL / min, the dropping rate of mixed solution B is 0.05mL / min, react for 8 to 10h, get Reaction solution; then the reaction solution is centrifuged to collect the solid phase; c, the solid phase is cleaned with a mass percentage of 99.7% ethanol solution, and then centrifuged to collect the solid phase; d, repeat step c operation 3 ~5 times; then the solid phase was placed in a 60°C oven for drying to obt...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the silicon dioxide seed solution described in step 1 is prepared according to the following steps: 364mg L-arginine is added to 276mL distilled water, and after dissolving, add 18mL of cyclohexane, heated to 60°C in a water bath, then stirred with a polytetrafluoroethylene paddle at a speed of about 300rpm, then added 22mL of distilled tetraethyl orthosilicate, and stirred at constant temperature for 20h to obtain a silica seed solution. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the reaction 8h described in step b. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com