Method of preparing immobilized lipase

A technology for immobilizing lipase and lipase, which is applied in the direction of immobilization on/in organic carriers, fermentation, etc., to achieve the effects of reducing high cost, increasing the number of repeated recycling and increasing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

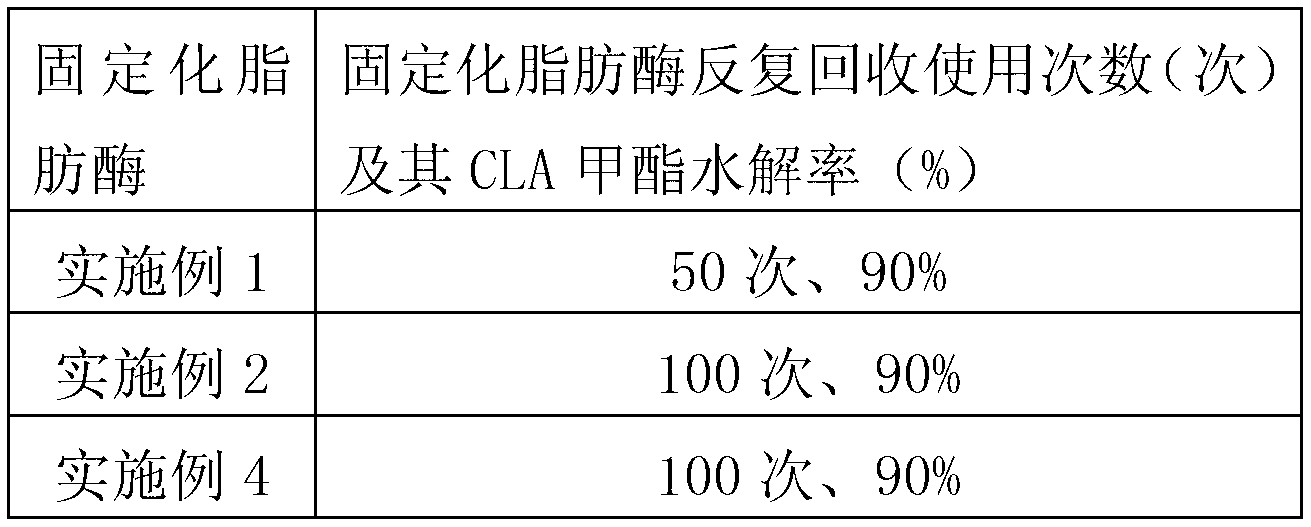

Examples

Embodiment 1

[0052] (1) Weigh 10g of macroporous ion exchange resin (Amberlite XAD761), add 10ml of absolute ethanol to soak for 2 hours, filter and discard the absolute ethanol, and rinse the remaining absolute ethanol in the resin with pure water to obtain activated macroporous ions Exchange resin (moisture content 70%);

[0053] (2) Add 20g of liquid lipase (10000U / g) from Pseudoalcaligenes (P.pseudoalcaligenes), add 2.7g of dipotassium hydrogen phosphate, stir and dissolve until completely, and adjust the pH to 8.0 with 10% NaOH aqueous solution ±0.5, dilute to 100g with pure water, then add 100mg of glucose, stir and dissolve to obtain lipase enzyme liquid;

[0054] (3) Preparation of 1% cross-linking agent: 10ml of glutaraldehyde solution (50%) was diluted to 500ml with purified water;

[0055] (4) Add 10 g of the solvent-treated macroporous resin obtained in step (1), 10 ml of the 1% crosslinking agent solution obtained in step (3) and 100 g of lipase enzyme solution obtained in st...

Embodiment 2

[0059] (1) According to the method of embodiment 1 step (1), the activated macroporous ion exchange resin is obtained;

[0060] (2) Add 10g of liquid lipase (10000U / g) from P.pseudoalcaligenes to 10g of 0.02% sodium caseinate protein aqueous solution, stir well, add 2.7g of dipotassium hydrogen phosphate, Stir and dissolve until complete, adjust the pH to 8.0±0.5 with 10% NaOH aqueous solution, dilute to 100g with pure water, add 100mg of glucose, stir and dissolve to obtain lipase enzyme liquid;

[0061] (3) 1% cross-linking agent: add 10ml formaldehyde solution (50%) and dilute to 500ml with purified water.

[0062] (4) Add 10 g of the solvent-treated macroporous resin obtained in step (1), 10 ml of the 0.1% crosslinking agent solution obtained in step (3) and 100 g of lipase enzyme solution obtained in step (2) into the continuous mixer. Stir at 25°C and 120rpm for 12h, filter, discard the filtrate to obtain a solid product;

[0063] (5) Add 50ml of 0.1% sodium caseinate ...

Embodiment 3

[0066] (1) The treatment method of the ion exchange resin (Amberlite XAD7HP) is the same as in Example 1.

[0067] (2) Add 10g of liquid lipase (10000U / g) from C.Antarctica to 10g of 0.02% bovine serum albumin aqueous solution, stir evenly, add 2.7g of dipotassium hydrogen phosphate, stir to dissolve Completely, use 10% NaOH aqueous solution to adjust the pH to 8.0±0.5, dilute to 100g with pure water, add 100mg trehalose, stir and dissolve to obtain lipase enzyme liquid;

[0068] (3) 1% crosslinking agent solution: add 10g polycarbodiimide solution (50%) and dilute to 500ml with purified water;

[0069] (4) Add 10 g of the activated ion exchange resin obtained in step (1), 10 ml of the 1% crosslinking agent solution obtained in step (3) and 100 g of lipase enzyme solution obtained in step (2) into the continuous mixer. Stir at 120 rpm for 12 hours at °C, filter, discard the filtrate to obtain a solid product;

[0070] (5) Add 100ml of 0.3% polyvinyl alcohol aqueous solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com