A kind of method of catalytic CO2 synthesis methanol modified cuznzr

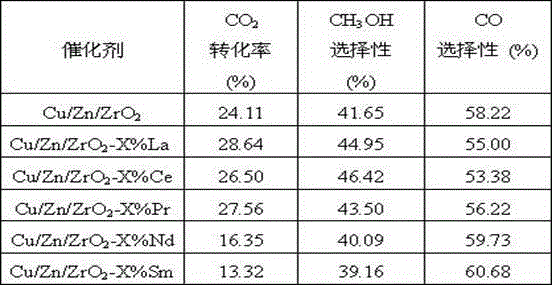

A technology for methanol synthesis and modification, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problem of low catalytic activity of catalysts, achieve high CO2 conversion rate and methanol selectivity, and improve interaction , to promote the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] Embodiment 1: The catalytic CO of this example 2 The method of synthetic methanol modified CuZnZr catalyst is:

[0021] (1) Configure Cu(NO 3 ) 2 , Zn(NO 3 ) 2 and Zr(NO 3 ) 4 The mixed solution, the molar ratio of Cu, Zn and Zr in the mixed solution is 0.3:0.5:0.2, and the concentration of Cu, Zn or Zr ions is 0.8mol / L;

[0022] (2) Keeping the temperature of the water bath at 60°C and stirring constantly, mix La 2 o 3 Add in the mixed solution of step (1), wait for La 2 o 3 After complete dissolution, the mixed solution was mixed with Na at a concentration of 0.1mol / L 2 CO 3 Solution parallel flow titration, keep the pH value of the mixed solution at 7 during the titration process, and then use Na 2 CO 3 Adjust the pH value of the mixed solution to 8, stop stirring and aging for 2 hours, and then suction filter 5 times. The filter cake is dried, ground, roasted and granulated in sequence in an air atmosphere to obtain a 20-40 mesh methanol-modified CuZnZr...

Embodiment approach 2

[0023] Embodiment 2: The catalytic CO of this embodiment 2 The method of synthetic methanol modified CuZnZr catalyst is:

[0024] (1) Configure Cu(NO 3 ) 2 , Zn(NO 3 ) 2 and Zr(NO 3 ) 4 The mixed solution, the molar ratio of Cu, Zn and Zr in the mixed solution is 0.3:0.5:0.1, and the concentration of Cu, Zn or Zr ions is 0.1mol / L;

[0025] (2) Keeping the temperature of the water bath at 60-80°C and stirring constantly, mix CeO 2 Add to the mixed solution of step (1) and wait for CeO 2 After complete dissolution, mix the solution with a concentration of 0.8mol / LNa 2 CO 3 Solution co-current titration, keep the pH value of the mixed solution at 7.5 during the titration process, after the titration, then use Na 2 CO 3The solution adjusted the pH value of the mixed solution to 8, stopped stirring and aging for 3 hours, and then suction filtered 6 times. The filter cake was sequentially dried, ground, roasted and granulated in an air atmosphere to obtain a 20-40 mesh me...

Embodiment approach 3

[0026] Embodiment 3: The catalytic CO of this embodiment 2 The method of synthetic methanol modified CuZnZr catalyst is:

[0027] (1) Configure Cu(NO 3 ) 2 , Zn(NO 3 ) 2 and Zr(NO 3 ) 4 The mixed solution, the molar ratio of Cu, Zn and Zr in the mixed solution is 0.45:0.45:1, and the concentration of Cu, Zn or Zr ions is 0.1mol / L;

[0028] (2) Keeping the temperature of the water bath at 80°C and stirring constantly, mix Pr 2 o 3 The agent is added to the mixed solution in step (1), and when Pr 2 o 3 After complete dissolution, mix the solution with a concentration of 1mol / LNa 2 CO 3 Solution co-current titration, keep the pH value of the mixed solution at 7.8 during the titration process, after the titration, then use Na 2 CO 3 The solution adjusted the pH value of the mixed solution to 8, stopped stirring and aging for 2.5 hours, and then suction-filtered 7 times. The filter cake was sequentially dried, ground, roasted and granulated in an air atmosphere to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com