Microwave doped sintering method of high-density and low-resistance ITO (Indium Tin Oxide) target

A sintering method and low-resistance technology, which is applied in the field of ITO target preparation, can solve the problems of long production cycle and low production efficiency, achieve fast heating speed, increase production efficiency, and improve microstructure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

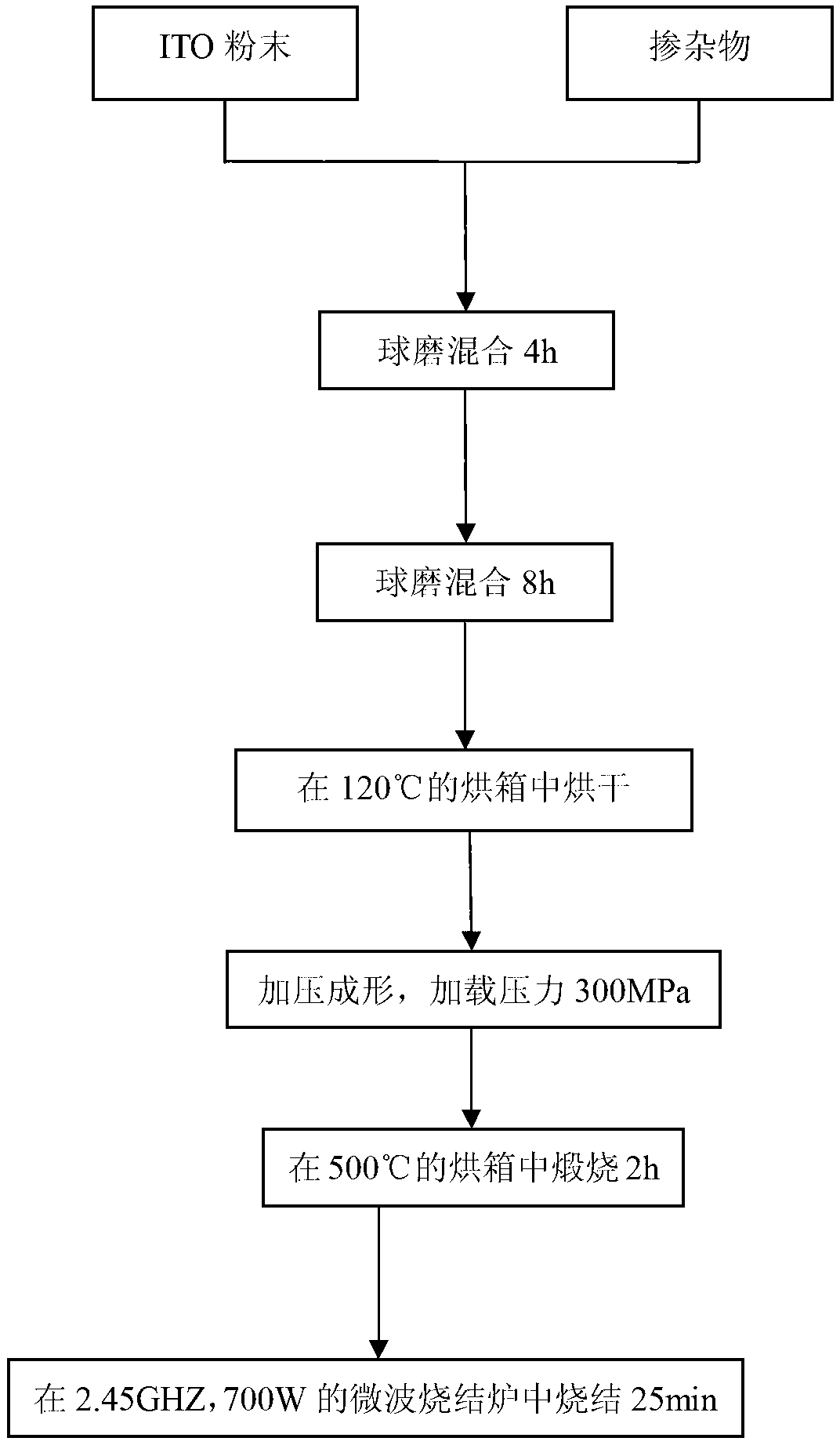

Method used

Image

Examples

Embodiment 1

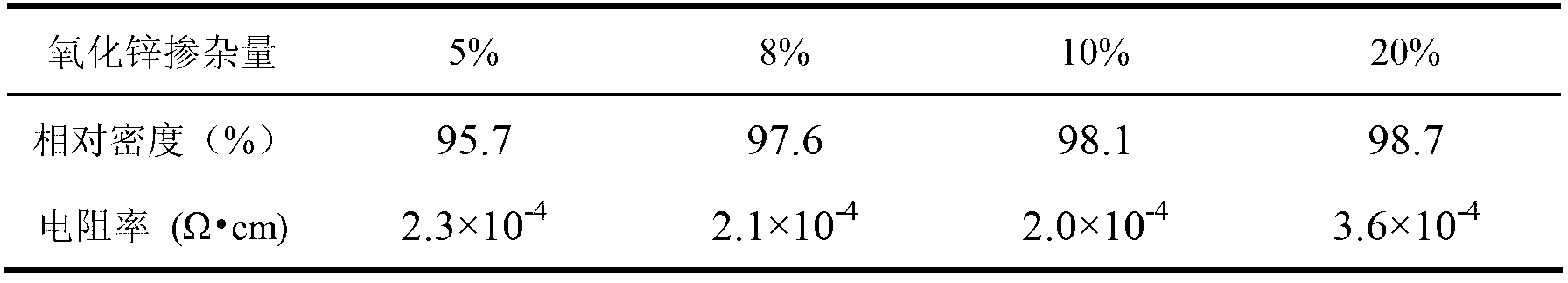

[0021] Weigh 0.8g of polyvinyl butyral, add it into 10ml of absolute ethanol, stir and dissolve to form 8% polyvinyl butyral binder; weigh 0.2g of zinc oxide powder and 4g of ITO powder (the mass of zinc oxide powder is 5% of the mass of ITO powder) into the ball mill tank, and add an appropriate amount of absolute ethanol (the mass ratio of the volume of absolute ethanol to the powder is 4:1), and ball mill for 4 hours; after the powder and absolute ethanol are mixed evenly , add the binder solution prepared above into the ball mill tank (the mass ratio of the volume of the binder solution to the powder is 3:8), and continue the ball milling for 8 hours to mix the binder and the powder evenly; the powder after ball milling Dry it in an oven at 120°C and grind it; after grinding, put the powder into a stainless steel mold with a diameter of 20mm and press it into a mold with a loading pressure of 300MPa; calcinate the formed compact in a muffle furnace at 500°C for 2 hours to r...

Embodiment 2

[0023]Weigh 0.8g of polyvinyl butyral, add it into 10ml of absolute ethanol, stir and dissolve into 8% polyvinyl butyral binder; weigh 0.32g of zinc oxide powder and 4g of ITO powder (the mass of zinc oxide powder It is 8% of the mass of ITO powder) into the ball mill tank, and add an appropriate amount of absolute ethanol (the mass ratio of the volume of absolute ethanol to the powder is 4:1), and ball mill for 4 hours; after the powder and absolute ethanol are mixed evenly , add the binder solution prepared above into the ball mill tank (the mass ratio of the volume of the binder solution to the powder is 3:8), and continue the ball milling for 8 hours to mix the binder and the powder evenly; the powder after ball milling Dry it in an oven at 120°C and grind it; after grinding, put the powder into a stainless steel mold with a diameter of 20mm and press it into a mold with a loading pressure of 300MPa; calcinate the formed compact in a muffle furnace at 500°C for 2 hours to r...

Embodiment 3

[0025] Weigh 0.8g of polyvinyl butyral, add it to 10ml of absolute ethanol, stir and dissolve into 8% polyvinyl butyral binder; weigh 0.4g of zinc oxide powder and 4g of ITO powder (the mass of zinc oxide powder is 10% of the mass of ITO powder) into the ball mill tank, and add an appropriate amount of absolute ethanol (the mass ratio of the volume of absolute ethanol to the powder is 4:1), and ball mill for 4 hours; after the powder and absolute ethanol are mixed evenly , add the binder solution prepared above into the ball mill tank (the mass ratio of the volume of the binder solution to the powder is 3:8), and continue the ball milling for 8 hours to mix the binder and the powder evenly; the powder after ball milling Dry it in an oven at 120°C and grind it; after grinding, put the powder into a stainless steel mold with a diameter of 20mm and press it into a mold with a loading pressure of 300MPa; calcinate the formed compact in a muffle furnace at 500°C for 2 hours to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com