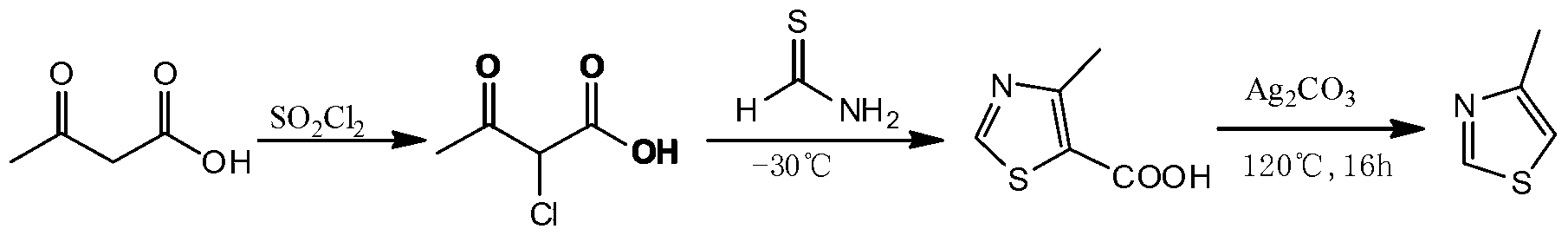

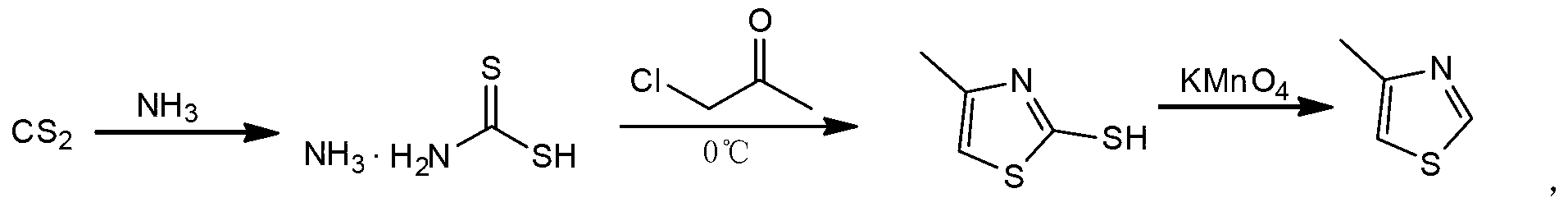

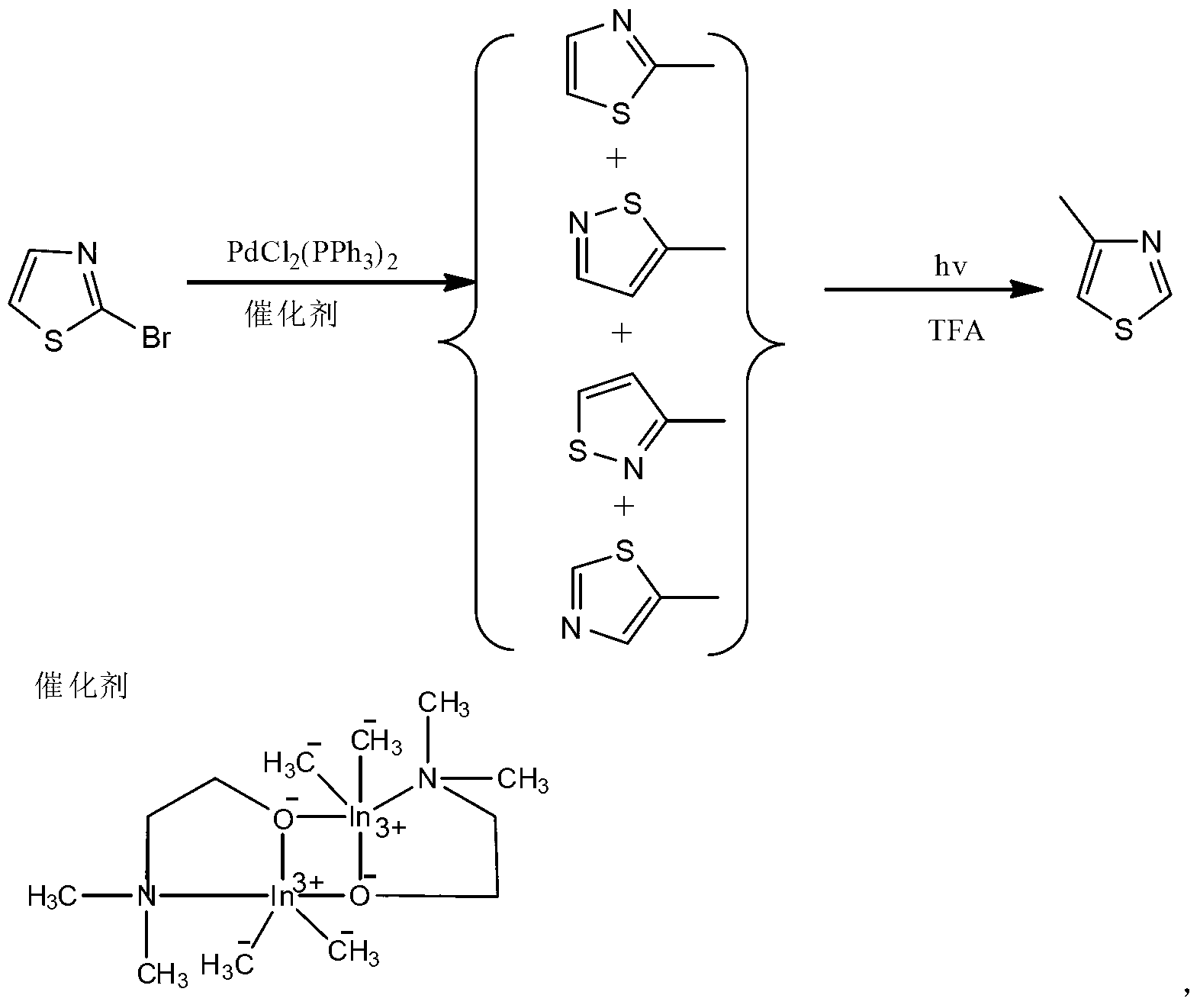

Preparation method of 4-methylthiazol

A technology of methylthiazole and formamide, which is applied in the field of preparation of 4-methylthiazole, can solve the problems of long reaction route of methylthiazole, complicated reaction and difficult control, and high catalyst production cost, and achieves convenient recovery and reuse, and reaction time. Short, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the preparation method of the 4-methylthiazole of the present embodiment is carried out according to the following steps:

[0022] 1. Preparation of thioformamide: add formamide to the solvent, add phosphorus pentasulfide under stirring state at room temperature, after the addition is completed, heat up to 45-50°C, react for 2 hours, then cool to room temperature, filter, and collect the filtrate. Obtain the mixed solution containing thioformamide; Wherein, the mass ratio of described solvent and formamide is 1.5~4:1, the mass ratio of described phosphorus pentasulfide and formamide is 1.0~1.1:1, described phosphorus pentasulfide It is added in batches, specifically: weigh phosphorus pentasulfide according to the mass ratio of phosphorus pentasulfide and formamide in the ratio of 1.0 to 1.1:1, add the weighed phosphorus pentasulfide in 8 to 10 batches, add a batch of phosphorus pentasulfide every 20 to 30 minutes, and add a batch of phosphorus pe...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solvent described in step 1 is anhydrous ethylene glycol dimethyl ether or dioxane. Other steps and parameters are the same as those in Embodiment 1.

[0025] The anhydrous ethylene glycol dimethyl ether of the present embodiment adopts phosphorus pentoxide to remove water to obtain anhydrous ethylene glycol dimethyl ether.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the temperature in step 1 is raised to 45-50° C., and the reaction is carried out for 2 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com