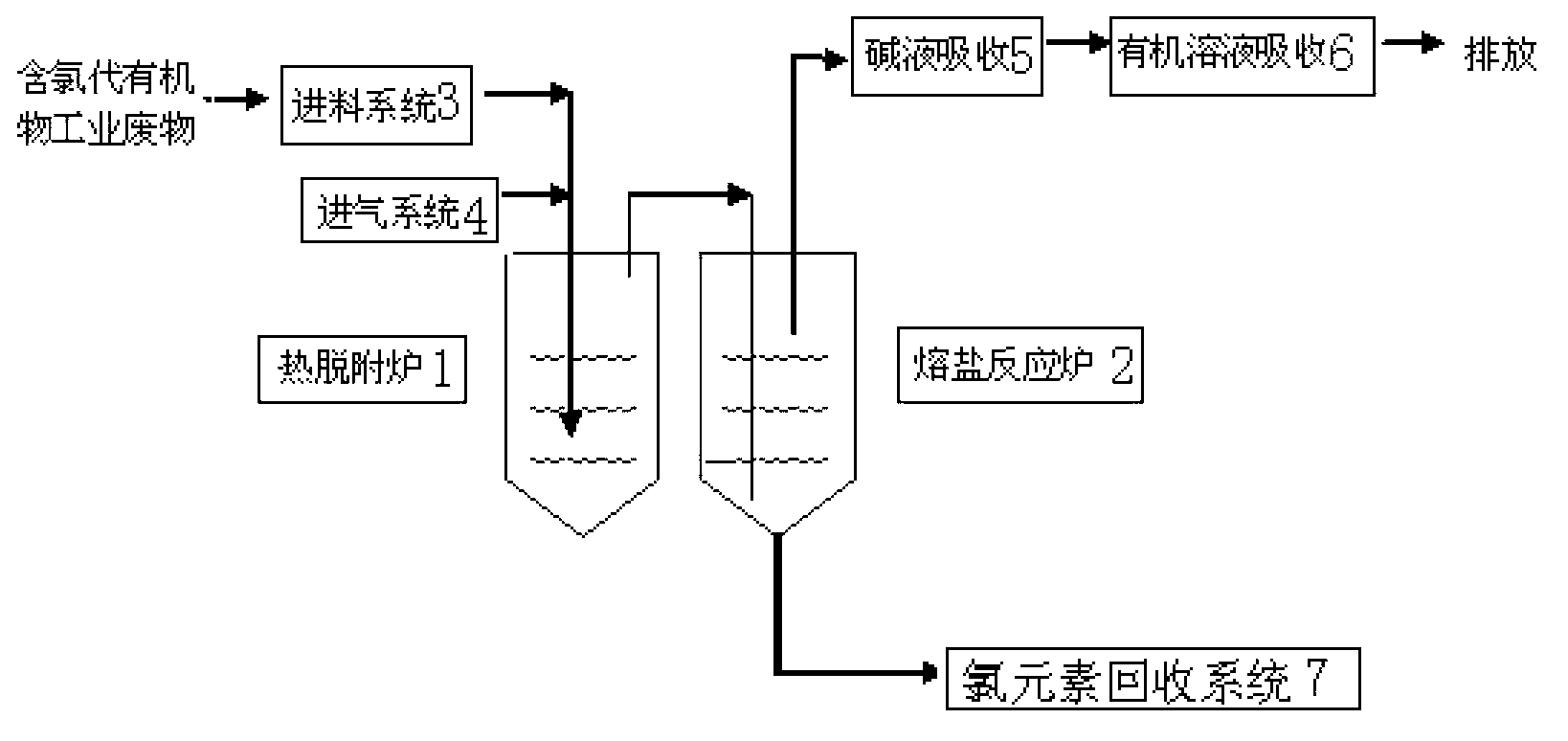

Device and method for processing chloro-containing organic industrial waste

A technology for chlorinated organic matter and industrial waste, applied in the direction of combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of incomplete degradation, secondary pollution, high equipment requirements, etc., achieve high destruction and removal rates, and equipment can be used Mobile, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A treatment method for a treatment device containing chlorinated organic industrial waste, comprising the following steps:

[0030] 1) After crushing the hexachlorobenzene-contaminated soil, feed it into the thermal desorption furnace 1 through the feed system 3;

[0031] 2) Through the temperature control system, the molten salt reaction furnace 2 is heated to melt the molten salt;

[0032] 3) Open the intake system 4, heat the thermal desorption furnace 1, desorb the organic chlorine in the hexachlorobenzene-contaminated soil and enter the molten salt reaction furnace 2 for reaction, and control the introduction rate of thermal desorption gas to 0.2L / min;

[0033] 4) The tail gas produced by the molten salt reactor 2 is discharged after being absorbed by sodium hydroxide solution with a mass concentration of 5% and methylene chloride;

[0034] 5) After the reaction, the material in the thermal desorption furnace 1 is emptied, and the next batch of material is added; ...

Embodiment 2

[0037] A treatment method for a treatment device containing chlorinated organic industrial waste, comprising the following steps:

[0038] 1) Crush the DDT-contaminated soil and feed it into the thermal desorption furnace 1 through the feed system 3;

[0039] 2) Through the temperature control system, the molten salt reaction furnace 2 is heated to melt the molten salt;

[0040] 3) Open the intake system 4, heat the thermal desorption furnace 1, desorb the organic chlorine in the DDT-contaminated soil and enter the molten salt reaction furnace 2 for reaction, and control the introduction rate of thermal desorption gas to 0.5L / min;

[0041] 4) The exhaust gas produced by molten salt reactor 2 is discharged after being absorbed by sodium hydroxide solution with a mass concentration of 10% and n-hexane;

[0042] 5) After the reaction, the material in the thermal desorption furnace 1 is emptied, and the next batch of material is added;

[0043] 6) After more than two batches of ...

Embodiment 3

[0045] A treatment method for a treatment device containing chlorinated organic industrial waste, comprising the following steps:

[0046] 1) After crushing the aldrin-contaminated soil, feed it into the thermal desorption furnace 1 through the feeding system 3;

[0047] 2) Through the temperature control system, the molten salt reaction furnace 2 is heated to melt the molten salt;

[0048] 3) Turn on the intake system 4, heat the thermal desorption furnace 1, desorb the organic chlorine in the aldrin-contaminated soil and enter the molten salt reaction furnace 2 for reaction, and control the introduction rate of thermal desorption gas to 0.3L / min;

[0049] 4) The tail gas produced by molten salt reactor 2 is discharged after being absorbed by potassium hydroxide solution with a mass concentration of 6% and methylene chloride;

[0050] 5) After the reaction, the material in the thermal desorption furnace 1 is emptied, and the next batch of material is added;

[0051] 6) Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com