Silver phosphate-bismuth vanadate multiplex photocatalyst and preparation method thereof

A photocatalyst, bismuth vanadate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of insufficient modification means, high charge recombination rate, low photocatalytic efficiency, etc. Achieve the effects of good visible light response performance, improved light response performance, and reduced recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

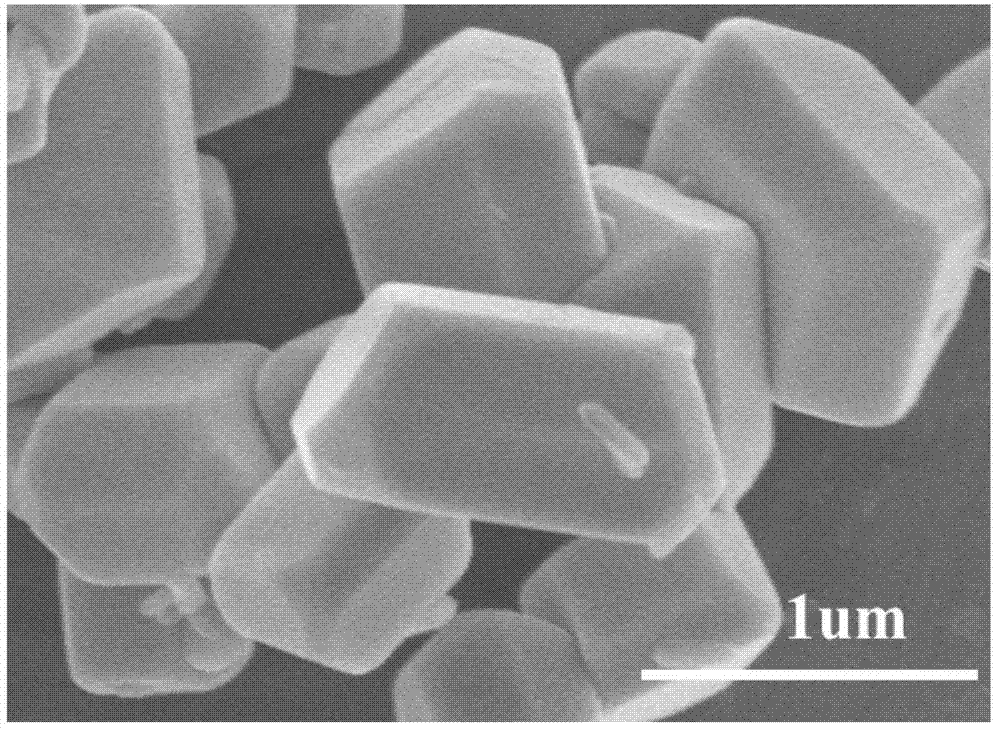

[0046] The first step: take 2.5mmol Bi(NO 3 ) 3 ·5H 2 Dissolve O in 50ml of dilute nitric acid solution (2M), add 0.5g of sodium dodecylsulfonate, stir for 60min to dissolve completely, and record it as solution A.

[0047] The second step: take 2.5mmol NH 4 VO 3 Dissolve in 50ml dilute ammonia solution (2M), stir for 60min to dissolve completely, and record it as solution B.

[0048] Step 3: Add solution A to solution B under vigorous stirring, continue stirring for 30 minutes, then slowly adjust the pH to 7 with ammonia solution, and continue stirring for 30 minutes.

[0049] Step 4: Transfer the obtained mixed solution into a crystallization kettle with a polytetrafluoroethylene liner, keep it at 180° C. for 24 hours, and cool it down to room temperature naturally.

[0050] Step 5: Centrifuge, wash three times with deionized water and three times with absolute ethanol, and dry at 80°C for 8 hours to obtain BiVO 4 nanoparticles.

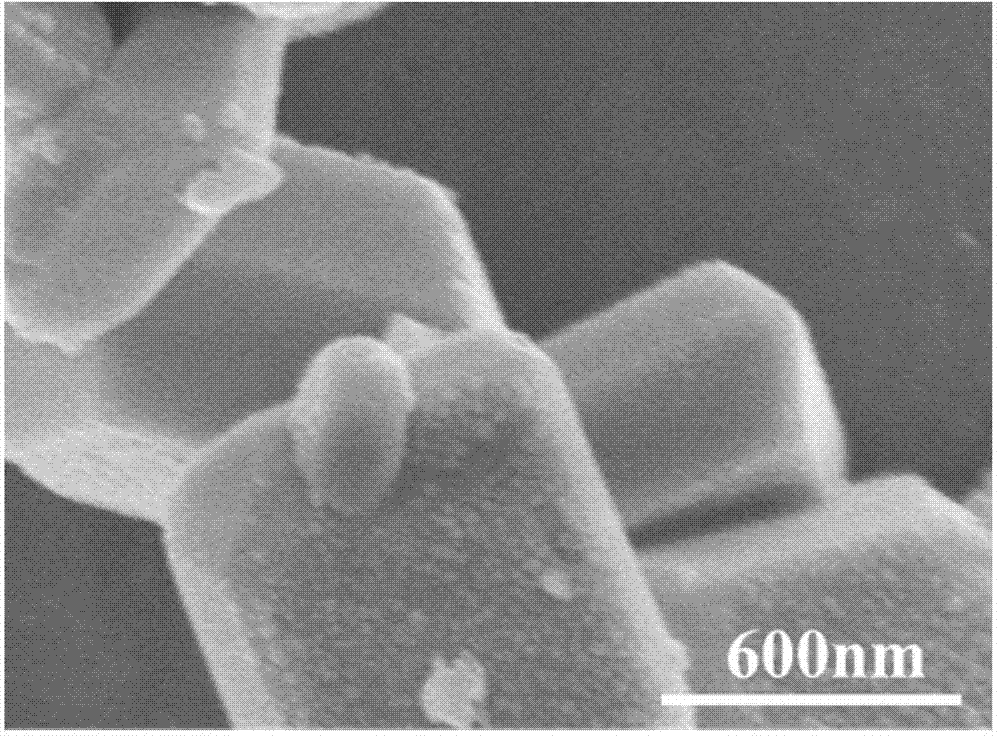

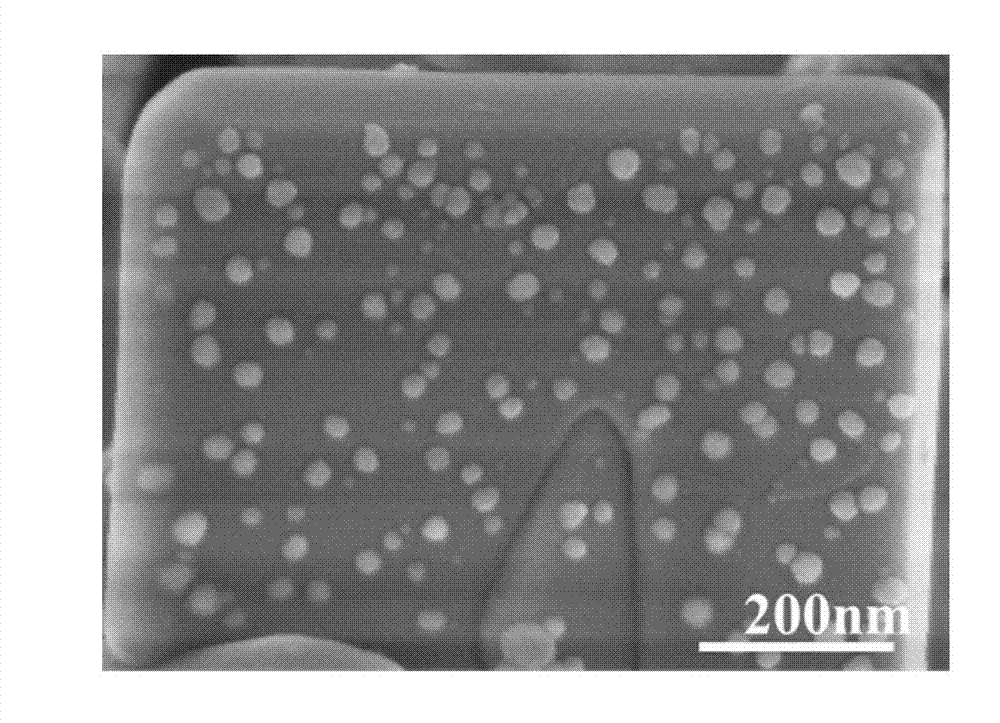

[0051] Step 6: Add 1mmol BiVO 4 Disp...

Embodiment 2

[0061] The first step: take 2.5mmol Bi(NO 3 ) 3 ·5H 2 Dissolve O in 60ml of dilute nitric acid solution (4M), add 0.65g of sodium dodecylsulfonate, stir for 30min to dissolve completely, and record it as solution A.

[0062] The second step: take 2.5mmol NH 4 VO 3 Dissolve in 60ml of dilute ammonia solution (4M), stir for 30min to dissolve completely, and record it as solution B.

[0063] Step 3: Add solution A to solution B under vigorous stirring, continue stirring for 30 minutes, then slowly adjust the pH to 8 with ammonia solution, and continue stirring for 120 minutes.

[0064] Step 4: Transfer the obtained mixed solution to a crystallization kettle with a polytetrafluoroethylene liner, keep it at 200° C. for 48 hours, and cool it down to room temperature naturally.

[0065] Step 5: centrifugation, washing with deionized water three times and absolute ethanol three times respectively, and drying at 100° C. for 12 hours to obtain bismuth vanadate nanoparticles.

[00...

Embodiment 3

[0075] The first step: take 2.5mmol Bi(NO 3 ) 3 ·5H 2 Dissolve O in 40ml of dilute nitric acid solution (1M), add 0.45g of sodium dodecylsulfonate, stir for 40min to dissolve completely, and record it as solution A.

[0076] The second step: take 2.5mmol NH 4 VO 3 Dissolve in 40ml of dilute ammonia solution (1M), stir for 40min to dissolve completely, and record it as solution B.

[0077] Step 3: Add solution A to solution B under vigorous stirring, continue stirring for 30 minutes, then slowly adjust the pH to 6.5 with ammonia solution, and continue stirring for 60 minutes.

[0078] Step 4: Transfer the obtained mixed solution to a crystallization kettle with a polytetrafluoroethylene liner, keep it at 160° C. for 12 hours, and cool it down to room temperature naturally.

[0079] Step 5: centrifuge, wash three times with deionized water and three times with absolute ethanol, and dry at 60° C. for 6 hours to obtain bismuth vanadate nanoparticles.

[0080] Step 6: Add 1mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com