Preparation method of graphene oxide modified polymer cement waterproof coating

A graphene-modified, waterproof coating technology, applied in the field of preparation of polymer cement waterproof coatings, can solve the problems of limited coating promotion and application, unsatisfactory mechanical properties, poor durability, etc., and achieves impermeability and improvement, good mechanics Performance and durability, the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

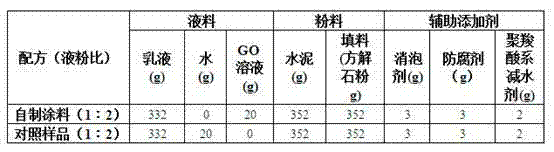

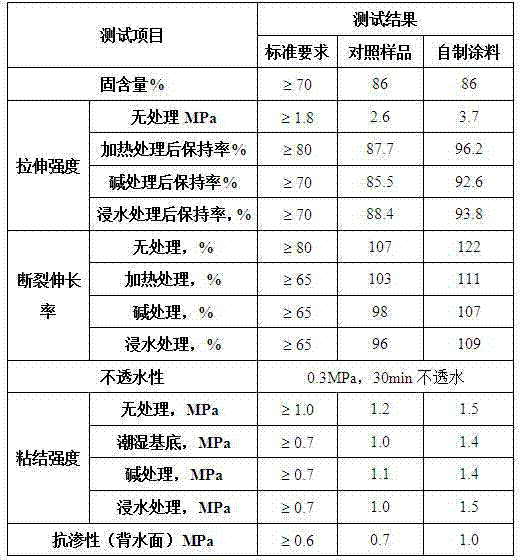

Method used

Image

Examples

Embodiment 1

[0032] Step 1: the preparation of graphene oxide:

[0033] Add 50 parts by mass of concentrated sulfuric acid with a mass fraction of 98%, 5 parts by mass of graphite powder and 5 parts by mass of sodium nitrate into the reactor, stir and control the temperature of the system to be less than 10°C, then add 18 parts by mass of high Potassium manganate is added to the reactor in batches, and the addition is completed within 1.5 hours; the temperature is raised to 35°C for 9 hours, and then the temperature is raised to 80°C for 1 hour, and then 600 parts of deionized water are added within 10 minutes; finally, the mass fraction is added dropwise 30% hydrogen peroxide until no bubbles are generated; vacuum filter, wash until the pH value is 7, and ultrasonically disperse for 2 hours to obtain a graphene oxide solution, and control its mass fraction to 0.65%;

[0034] Step 2: Preparation of Acrylic Polymer Emulsion:

[0035] Add 3.2 parts by mass of sodium lauryl sulfate, 4.0 part...

Embodiment 2

[0042] Step 1: the preparation of graphene oxide:

[0043] Add 50 parts by mass of concentrated sulfuric acid with a mass fraction of 98%, 5 parts by mass of graphite powder and 5 parts by mass of sodium nitrate into the reactor, stir and control the temperature of the system to be less than 10°C, then add 18 parts by mass of high Potassium manganate is added to the reactor in batches, and the addition is completed within 1.5 hours; the temperature is raised to 35°C for 9 hours, and then the temperature is raised to 80°C for 1 hour, and then 600 parts of deionized water are added within 10 minutes; finally, the mass fraction is added dropwise 30% hydrogen peroxide until no bubbles are generated; vacuum filter, wash until the pH value is 7, and ultrasonically disperse for 2 hours to obtain a graphene oxide solution, and control its mass fraction to 0.65%;

[0044] Step 2: Preparation of Acrylic Polymer Emulsion:

[0045] Add 3.2 parts by mass of sodium lauryl sulfate, 4.0 part...

Embodiment 3

[0052] Step 1: the preparation of graphene oxide:

[0053] Add 50 parts by mass of concentrated sulfuric acid with a mass fraction of 98%, 5 parts by mass of graphite powder and 5 parts by mass of sodium nitrate into the reactor, stir and control the temperature of the system to be less than 10°C, then add 18 parts by mass of high Potassium manganate is added to the reactor in batches, and the addition is completed within 1.5 hours; the temperature is raised to 35°C for 9 hours, and then the temperature is raised to 80°C for 1 hour, and then 600 parts of deionized water are added within 10 minutes; finally, the mass fraction is added dropwise 30% hydrogen peroxide until no bubbles are generated; vacuum filter, wash until the pH value is 7, and ultrasonically disperse for 2 hours to obtain a graphene oxide solution, and control its mass fraction to 0.65%;

[0054] Step 2: Preparation of Acrylic Polymer Emulsion:

[0055] Add 3.2 parts by mass of sodium lauryl sulfate, 4.0 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com