Method for preparing multibasic oxide nanometer particles based on core-shell structure three-dimensional micro-solid-phase reaction.

A nanoparticle, core-shell structure technology, applied in the field of material preparation, can solve the problems of many control factors in the preparation process, no preparation method of multi-component oxide nanoparticles, and different shapes of precursor precipitates, etc. The effect of forming temperature, controllable preparation, and avoiding powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using urea as a precipitating agent to prepare multiple oxide YAG nanopowders

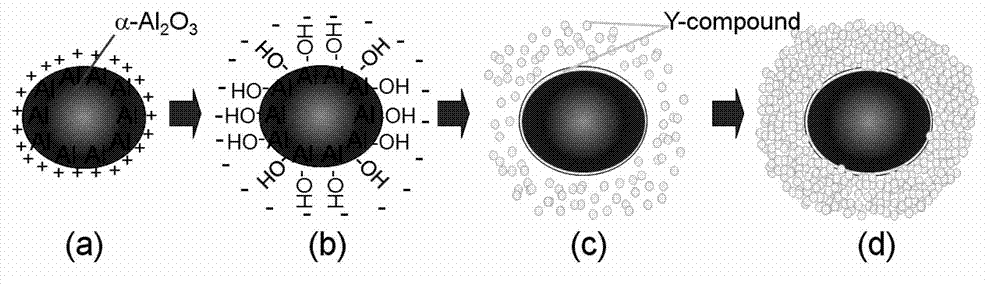

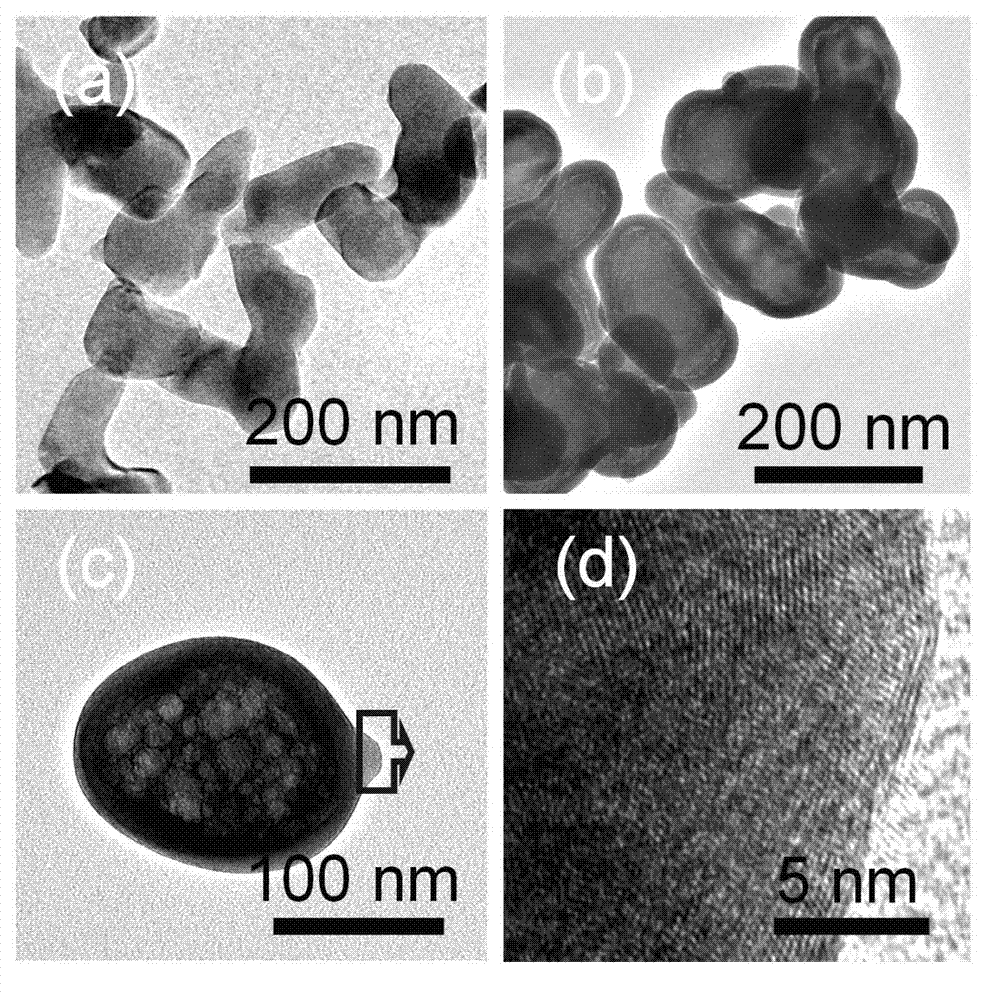

[0027] (1) For prefabricated YAG powder, select α-Al with spherical shape 2 o 3 As the core structure of the preparation process, the corresponding yttrium ions need to be precipitated and uniformly coated on α-Al 2 o 3 surface. The method is: take 10ml of yttrium nitrate solution with a concentration of 0.6mol / L, mix it well with 80ml of urea with a concentration of 0.5mol / L, raise the temperature to 95°C at 5°C / min, keep it warm for 3 hours, cool down naturally, and wash with water Obtain the precursor precipitation of yttrium element;

[0028] (2) Use the zeta potential meter to test the spherical nanoparticles α-Al respectively 2 o 3 The surface electrical properties of the precursor of yttrium and yttrium element precipitated in 0.05mol / L ammonium bicarbonate solution, it is determined that the surface electrical properties of the two are opposite;

[0029] (3) Weigh 1.28g of α-A...

Embodiment 2

[0033] Using ammonium bicarbonate as precipitant to prepare YAG nanopowder

[0034] (1) For prefabricated YAG powder, select α-Al with spherical shape 2 o 3 As the core structure of the preparation process, the corresponding yttrium ions need to be precipitated and uniformly coated on α-Al 2 o 3 surface. The method is: take 10ml of yttrium nitrate solution with a concentration of 0.6mol / L, add 0.5mol / L ammonium bicarbonate dropwise into the above solution at a rate of 2ml / min, and stir vigorously at the same time until the pH value of the mixed solution reaches 7.5, stop Ammonium bicarbonate was added dropwise, and the precursor precipitation of yttrium element was obtained after washing;

[0035] (2) Use the zeta potential meter to test the spherical nanoparticles α-Al respectively 2 o 3 The surface electrical properties of the precursor of yttrium and yttrium element precipitated in 0.05mol / L ammonium bicarbonate solution, it is determined that the surface electrical p...

Embodiment 3

[0040] Using ammonia as a precipitant to prepare YAG nanopowder

[0041] (1) For the preparation of YAG powder, select α-Al with spherical shape 2 o 3 As the core structure of the preparation process, the corresponding yttrium ions need to be precipitated and uniformly coated on α-Al 2 o 3 surface. The method is: take 10ml of yttrium nitrate solution with a concentration of 0.6mol / L, add 0.5mol / L ammonia water dropwise to the above solution at a rate of 2ml / min, and stir vigorously at the same time until the pH value of the mixed solution reaches 7.5, then stop dripping Add ammonia water, obtain the precursor precipitation of yttrium element after washing;

[0042] (2) Use the zeta potential meter to test the spherical nanoparticles α-Al respectively 2 o 3 The surface electrical properties of the precursors of yttrium and yttrium element precipitated in 0.05mol / L ammonia solution, confirm that the surface electrical properties of the two are opposite;

[0043] (3) Weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com