Method for separating and purifying tripterine from medicinal material celastrus orbiculatus

A technology for the separation and purification of tripterygne, which is applied in the field of separation and purification of tripteryne from the medicinal material of S. chinensis, can solve the problems of complex purification process, insufficient simplification of purification steps, large consumption, etc., and achieve simplified purification steps, purification Easy steps and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

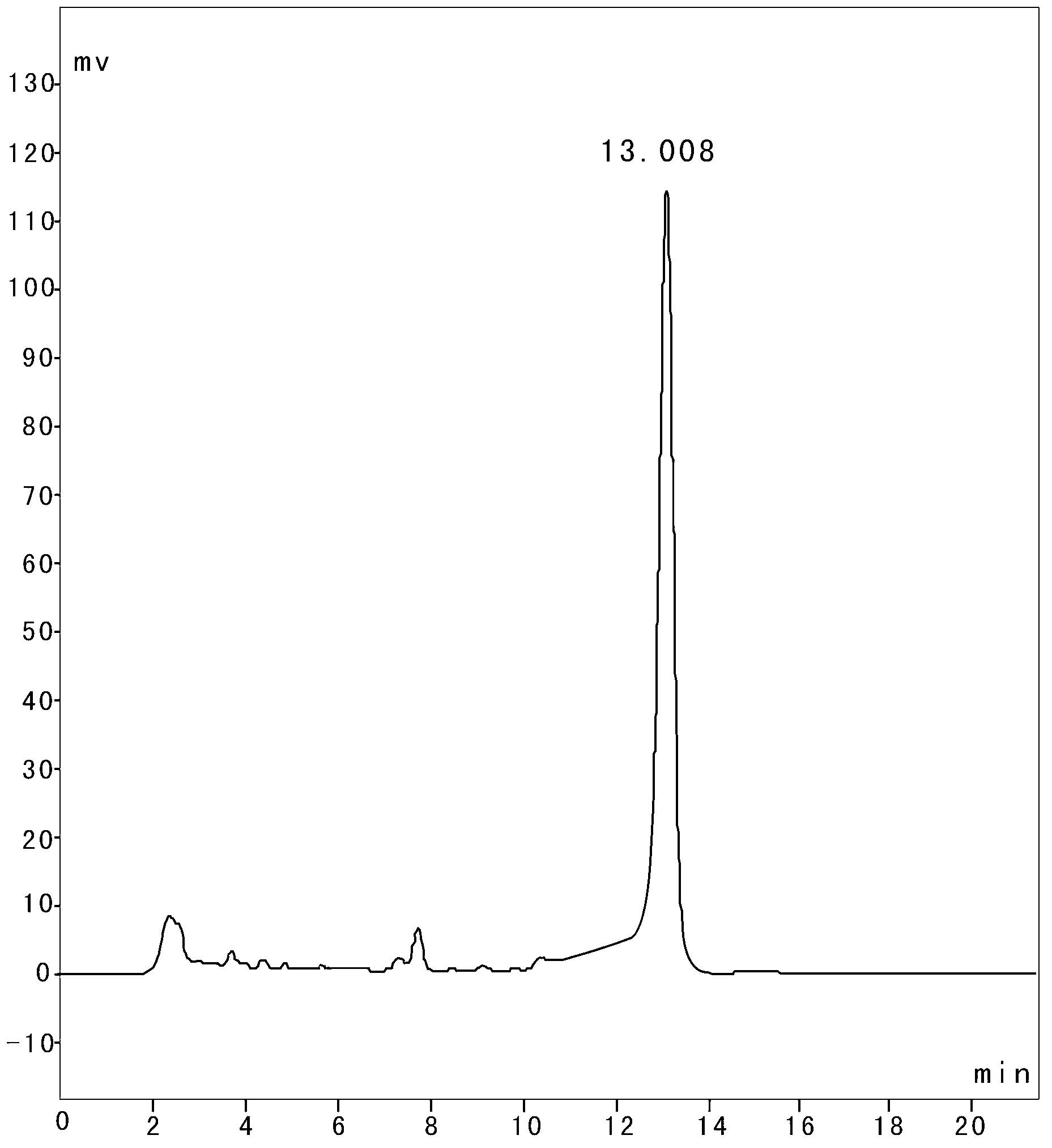

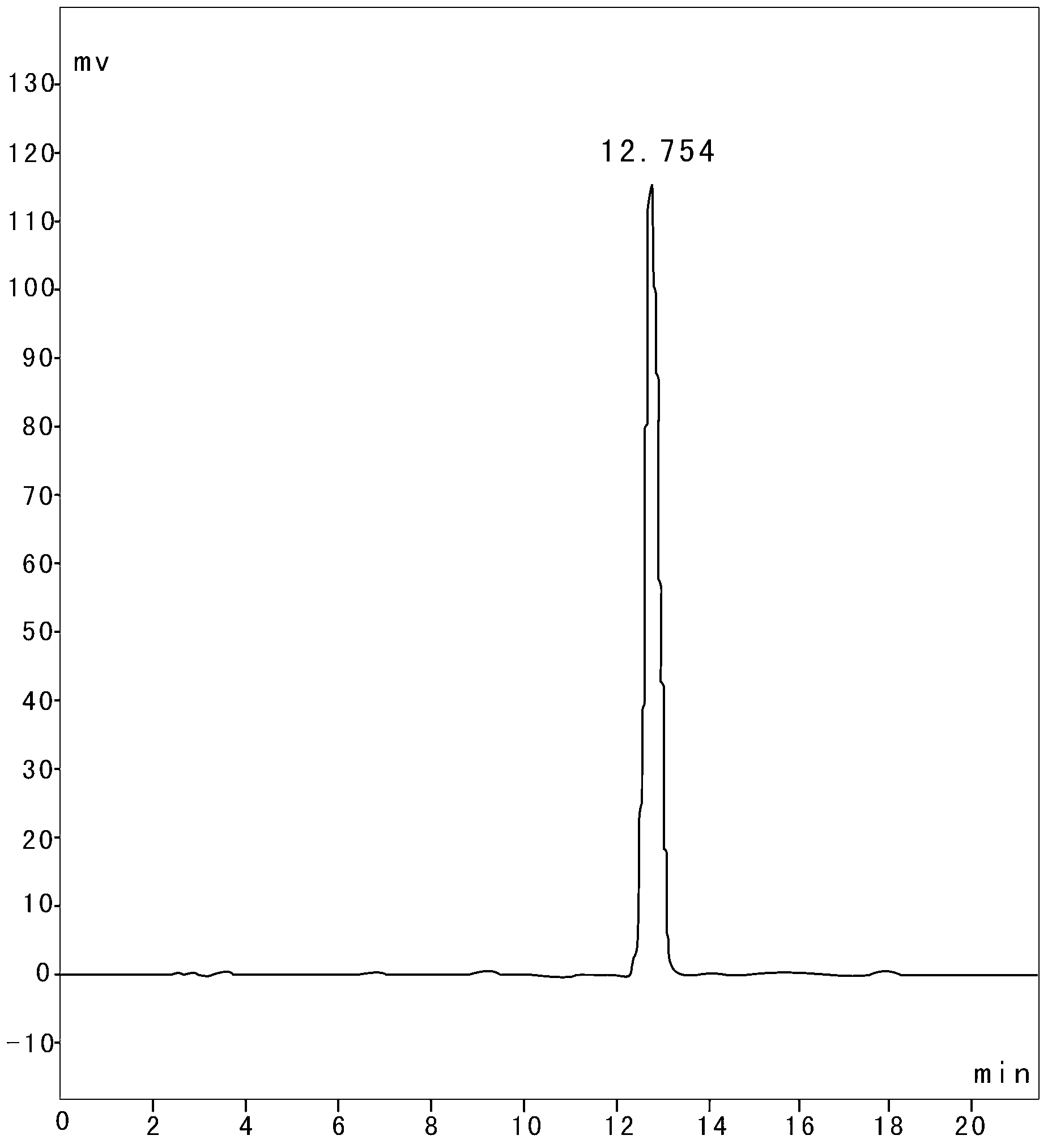

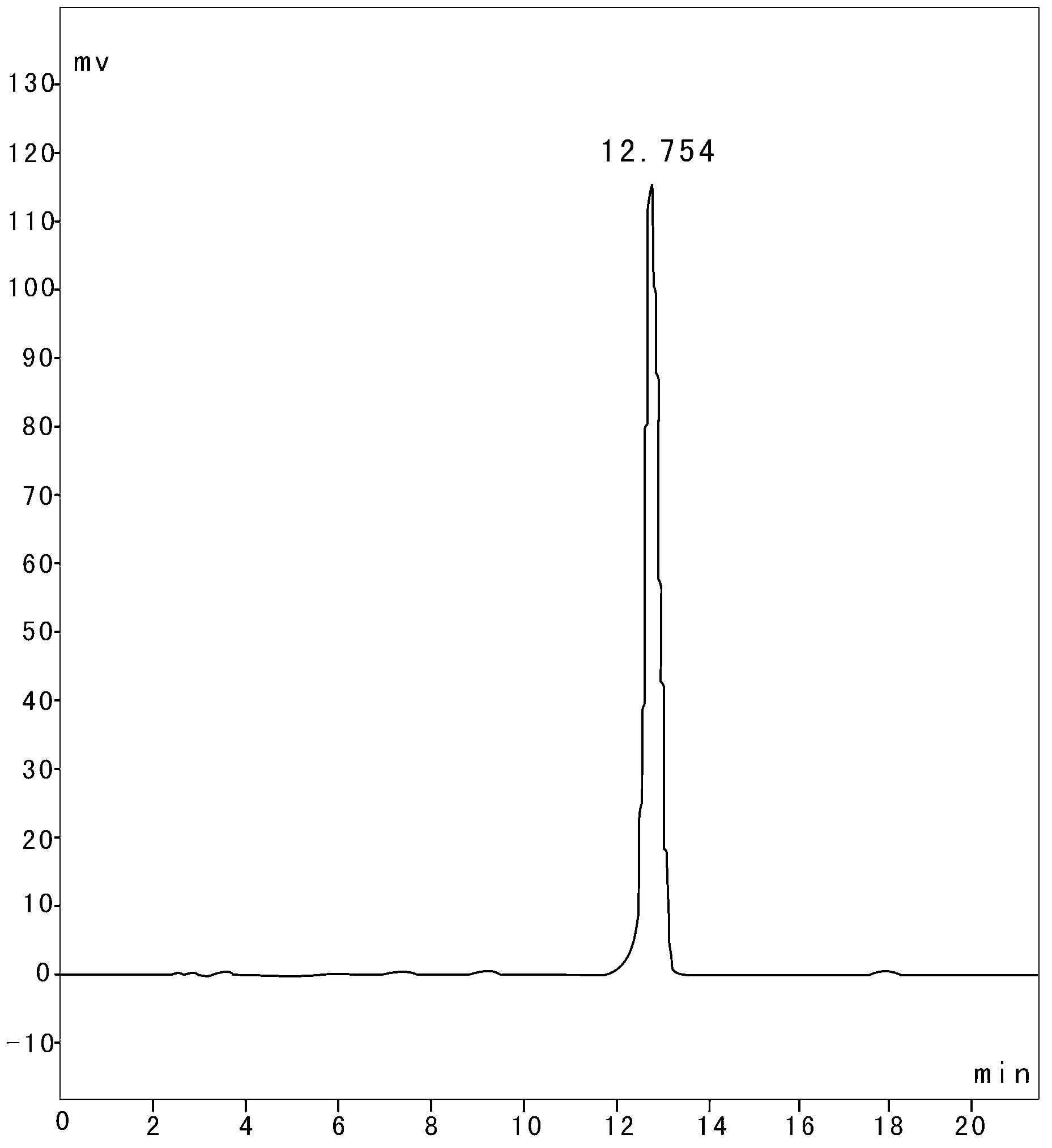

Image

Examples

Embodiment 1

[0032] Prepare tripteryglide monomer according to the following steps:

[0033] (1) Material preparation: Crush the above-ground vines and underground roots of S. chinensis into 2-5mm sections.

[0034] (2) Use 90% ethanol to reflux extract the crushed S. serpentine. The ratio of the mass of S. serpentine to the volume of ethanol is 1:10. The units are kilograms and liters respectively. The extraction temperature is 60°C , The extraction time is 5h; the extract is recovered at 60°C under reduced pressure to obtain a concentrated solution.

[0035] (3) Mix the concentrated solution obtained in the above step (2) with 60-80 mesh silica gel at a ratio of 1:1, dry it into dispersed particles, and obtain granular raw materials for later use.

[0036](4) Put 200-300 mesh silica gel in a dichloromethane-methanol solution with a volume ratio of 25:1 for wet packing. The diameter of the separation column is 15 cm, and use a dichloromethane-methanol solution with a volume ratio of 25:1...

Embodiment 2

[0039] Prepare tripteryglide monomer according to the following steps:

[0040] (1) Material preparation: Crush the above-ground vines and underground roots of S. chinensis into 2-5mm sections.

[0041] (2) Use 92% ethanol to reflux extract the crushed Snakevine segment. The ratio of the mass of S. Schidenia to the volume of ethanol is 1:15, and the units are kilograms and liters respectively. The extraction temperature is 65°C , The extraction time is 6h; the extract is recovered at 62°C under reduced pressure to obtain a concentrated solution.

[0042] (3) Mix the concentrated solution obtained in the above step (2) with 60-80 mesh silica gel at a ratio of 1:1, dry it into dispersed particles, and obtain granular raw materials for later use.

[0043] (4) Put 200-300 mesh silica gel in a dichloromethane-methanol solution with a volume ratio of 22:1 for wet packing. The diameter of the separation column is 18 cm, and use a dichloromethane-methanol solution with a volume ratio...

Embodiment 3

[0046] Prepare tripteryglide monomer according to the following steps:

[0047] (1) Material preparation: Crush the above-ground vines and underground roots of S. chinensis into 2-5mm sections.

[0048] (2) Use 95% ethanol to reflux extract the crushed S. serpentine. The ratio of the mass of S. serpentine to the volume of ethanol is 1:20. The units are kilograms and liters respectively. The extraction temperature is 70°C , The extraction time is 7h; the extract is recovered at 65°C under reduced pressure to obtain a concentrated solution.

[0049] (3) Mix the concentrated solution obtained in the above step (2) with 60-80 mesh silica gel at a ratio of 1:1, dry it into dispersed particles, and obtain granular raw materials for later use.

[0050] (4) Put 200-300 mesh silica gel in a dichloromethane-methanol solution with a volume ratio of 20:1 for wet packing. The diameter of the separation column is 20 cm, and use a dichloromethane-methanol solution with a volume ratio of 20:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com