Biodegradable composite material and preparation method thereof

A composite material and biodegradable technology, which is applied in the field of biodegradable composite materials and their preparation, can solve the problems of mechanical properties to be improved, limited application range, complex production process, etc., achieve excellent biodegradability, expand application fields, and solve white pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

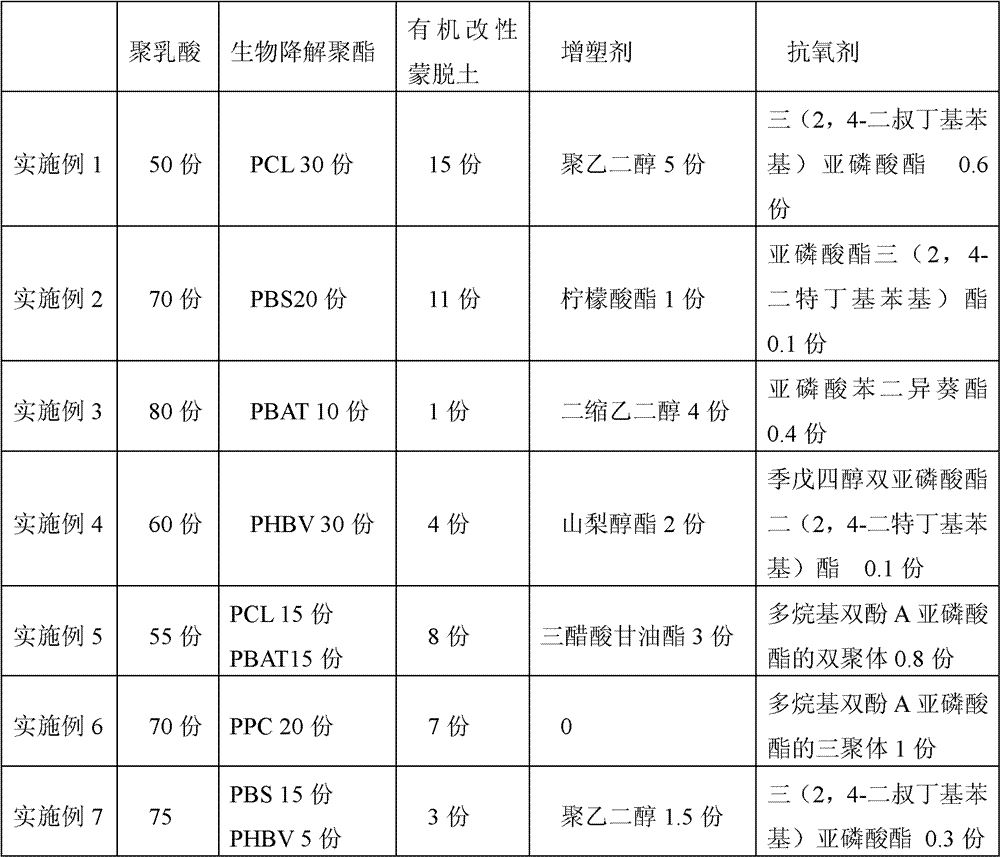

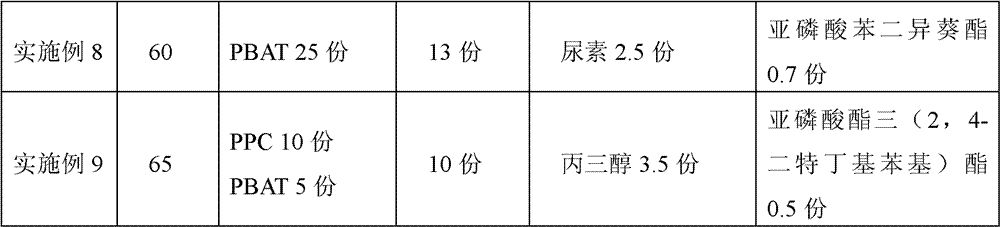

[0029] (1) Take the formula components of each weight part by the proportioning in Table 1.

[0030] Table 1

[0031]

[0032]

[0033] (2) Dry polylactic acid, biodegradable polyester, and organically modified montmorillonite in vacuum for 6-12 hours at a temperature of 60-90° C. to remove moisture.

[0034] (3) Add the dried polylactic acid, the dried biodegradable polyester, the dried organically modified montmorillonite, plasticizer and antioxidant to a high-speed mixer and blend for 5-10 minutes, and then The mixture is fed into a twin-screw extruder for melt blending and extrusion, and the extrusion temperature is 160-210°C;

[0035] Among them, Example 1 was blended for 5 minutes and the extrusion temperature was 160°C; Example 2 was blended for 8 minutes and the extrusion temperature was 170°C; Example 3 was blended for 7 minutes and the extrusion temperature was 180°C; Example 4 was blended for 6 minutes and extruded The temperature is 190°C; Example 5 is blen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com