Super-thickness film epoxy double-component anticorrosive paint

An anti-corrosion coating, two-component technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of anti-corrosion performance that cannot be used in actual use, adverse effects of waste on the environment, dry film thickness and thickness, etc., to achieve inhibition Solvent removal rate, reduced number of overhauls, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

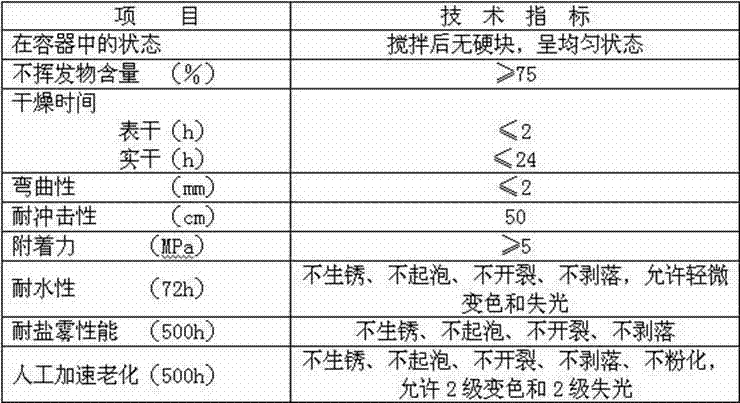

Image

Examples

Embodiment 1

[0055] The substance and weight percentage of A component are as follows:

[0056] Epoxy: 30

[0057] Amino resin: 2

[0058] Chlorinated paraffins: 5 Plasticizers

[0059] Anti-sedimentation agent: 1 additive

[0060] Defoamer: 0.5 additives

[0061] Titanium dioxide: 6

[0062] Talc: 5 fillers

[0063] Barium sulfate: 20 filler

[0065] Mica Iron Oxide: 20 filler

[0066] Leveling agent: 0.5 additive

[0068] Xylene: 3 Solvents

[0069] Cyclohexanone: 1 solvent

[0070] The substance and weight percentage of component B are as follows:

[0071] Substituted phenalkamine: 90

[0072] Butanol: 5

[0073] Xylene: 5

[0074] 1. Put 30Kg of epoxy resin, 2Kg of amino resin, 5Kg of chlorinated paraffin, 1Kg of anti-settling agent, 0.5Kg of defoamer, 6Kg of titanium dioxide, 5Kg of talcum powder, 20Kg of barium sulfate, 5Kg of mica powder, and Mix 1Kg of alcohol, 3Kg of xylene, and 1Kg of cyclohexanone, disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com