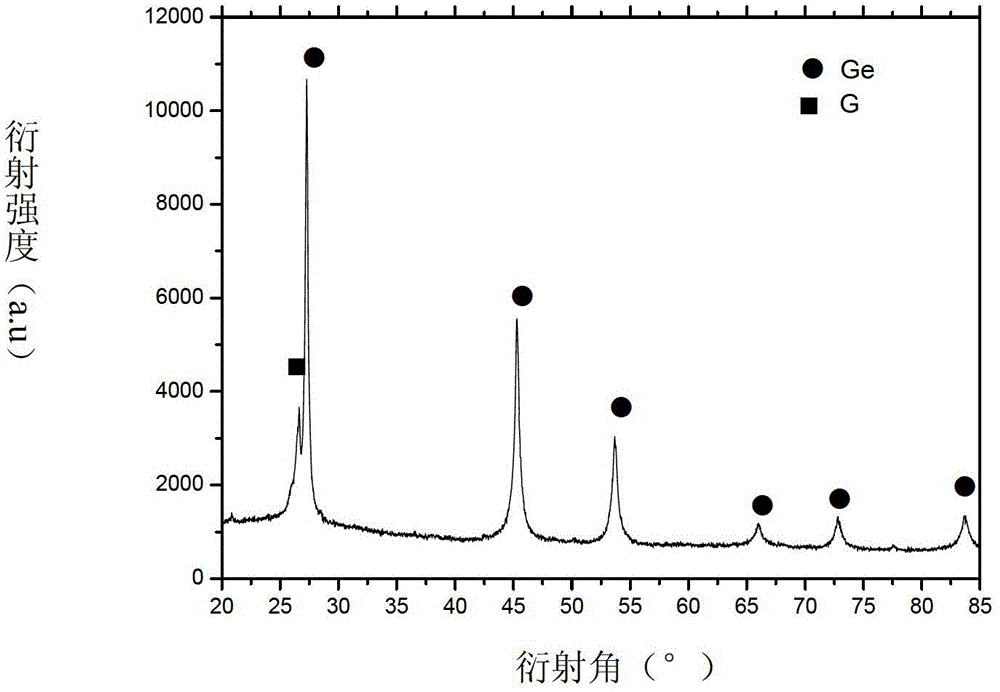

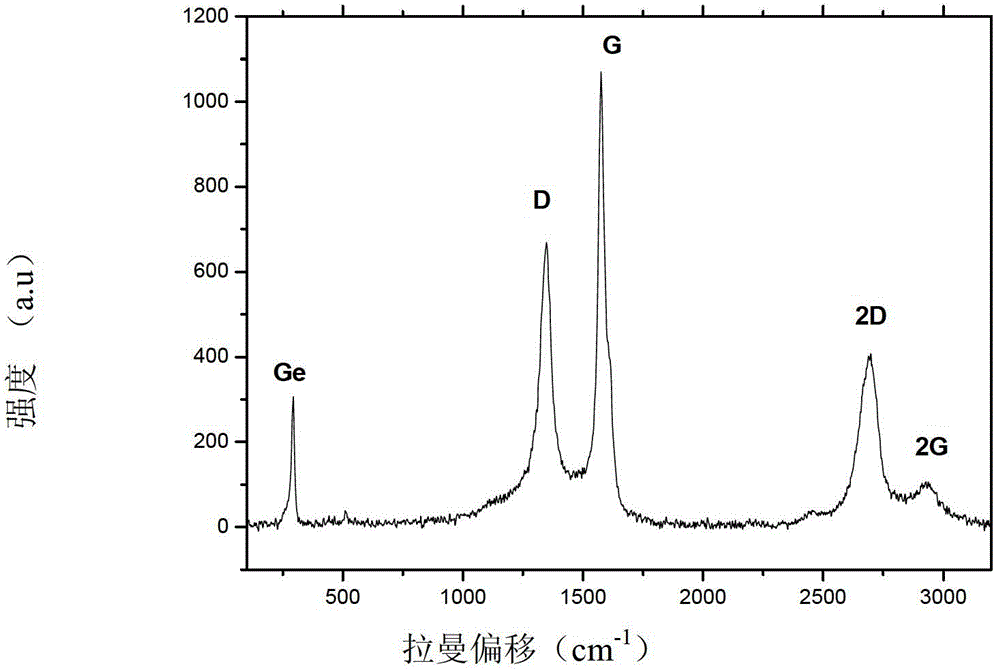

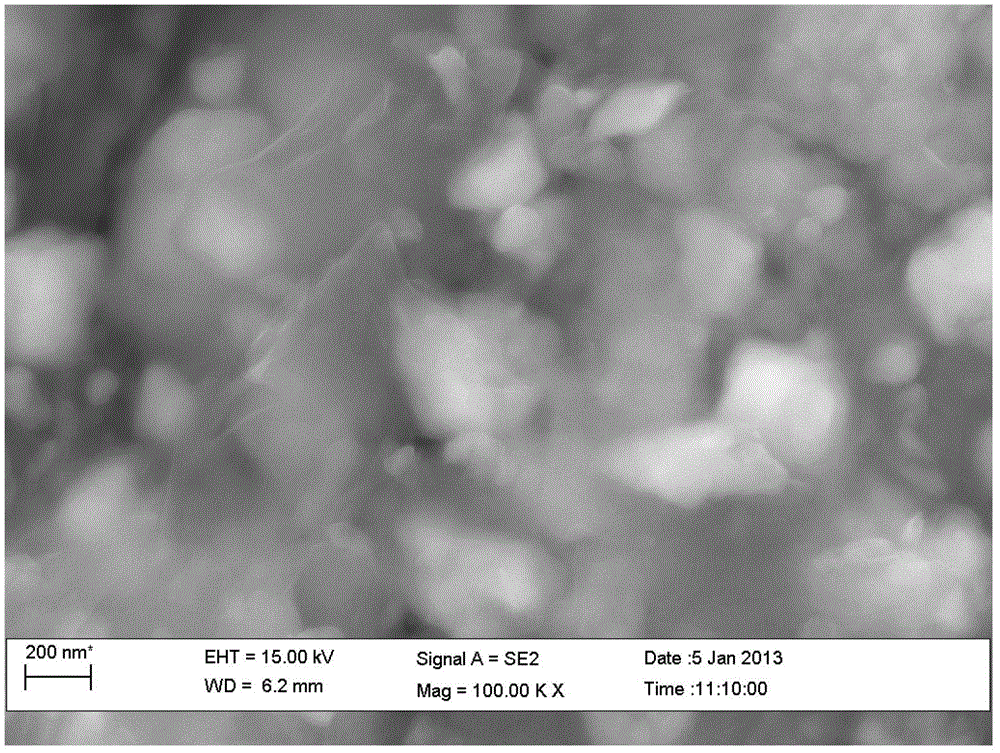

A kind of graphene-coated nano-germanium composite material and its preparation method and application

A graphene coating, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as inability to industrialize mass production, cumbersome process parameters, complex synthesis process, etc. The preparation method is simple, the cycle stability is good, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The specific steps of the dielectric barrier discharge plasma-assisted high-energy ball milling method are:

[0048] (1) Install the front cover and the electrode rod of the ball mill, and connect the iron core in the front cover and the electrode rod to the positive and negative stages of the plasma power supply respectively, wherein the iron core in the electrode rod is connected to the plasma power supply The positive pole of the front cover is connected to the negative pole of the plasma power supply;

[0049] (2) Put cemented carbide grinding balls (different in size) and original powder with a good ratio in the ball mill tank (ball powder ratio 50:1);

[0050] (3) Vacuum the ball mill tank through the vacuum valve, and then fill the discharge gas medium Ar gas, so that the pressure value in the ball mill tank reaches 0.12MPa;

[0051] (4) Turn on the plasma power supply, set the plasma power supply voltage to 15KV, the current to 1.5A, and the discharge frequency...

Embodiment 2

[0057] The difference between this embodiment and embodiment 1 is:

[0058] The mixing and ball milling time of the germanium raw material and the expandable graphite is 5 hours. The above-mentioned powders were made into negative electrode sheets of lithium-ion batteries, and the batteries were assembled for charge and discharge tests.

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is:

[0061] The germanium raw material and the expandable graphite are mixed and ball-milled for 10 hours. And the above-mentioned powder is made into the negative electrode sheet of the lithium ion battery, and after the battery is assembled, the charge and discharge test is carried out under the condition of 0.2C charge and discharge rate. Its initial discharge capacity is 1313mAhg -1 , the capacity remains at 845mAhg after 40 cycles -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com