Ceramic tile with natural-marble imitated lines and production method

A manufacturing method and marble technology, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of high radiation, poor wear resistance and anti-fouling performance, and achieve the effect of good anti-fouling, good performance index and fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

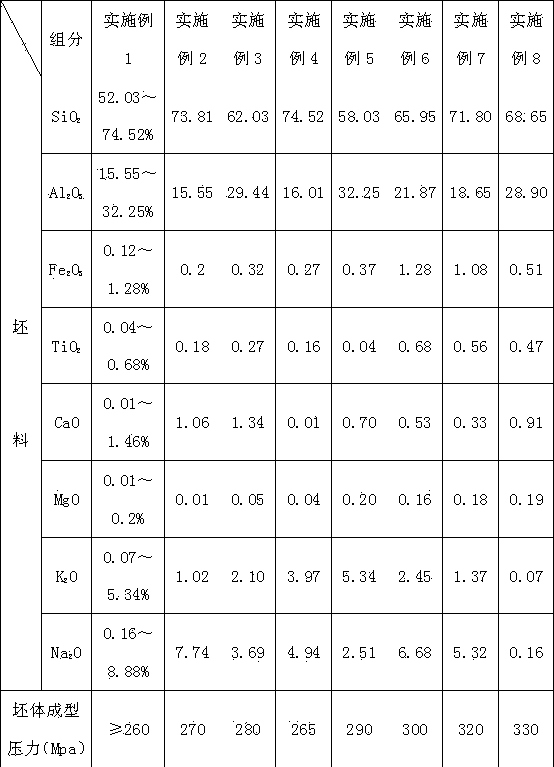

[0032] The present invention will be described in further detail below in conjunction with specific embodiment (the blank unit is mass percentage):

[0033]

[0034] Manufacturing method and process steps: purchasing→recipe formulation→ingredient ball milling→slurry→slurry stale→sieving iron removal→spray drying→powder→powder stale→distributing powder→cloth forming→drying→firing→polishing→ Grading→nanometer polishing→grading→packaging→warehousing.

[0035] The present invention mixes 10-50% by weight of translucent jade micropowder with 50-90% by weight of different color-developing adobe powders in the fabric of brick adobe, and makes random cloth; A kind of broken block micropowder fabric is mixed in proportion, and the fabric is formed into an irregular natural pile, which is evenly distributed in the brick fabric as a whole, and makes part of the fabric contain subtle lines like natural cracks; line material The percentage by weight is: 5-10%, the proportion is preset ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com