Preparation method and application of Fe-doped PTFE-PbO2/TiO2-NTs/Ti electrode

A ptfe-pbo2, electrode technology, applied in the direction of electrode, sterilization/microdynamic water/sewage treatment, electrolysis process, etc., can solve the problems that affect the continuous use of the electrode, the low bonding force of the Ti matrix, and the coating is easy to fall off, etc., to achieve catalytic Stable oxidation effect, reduced electrode cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

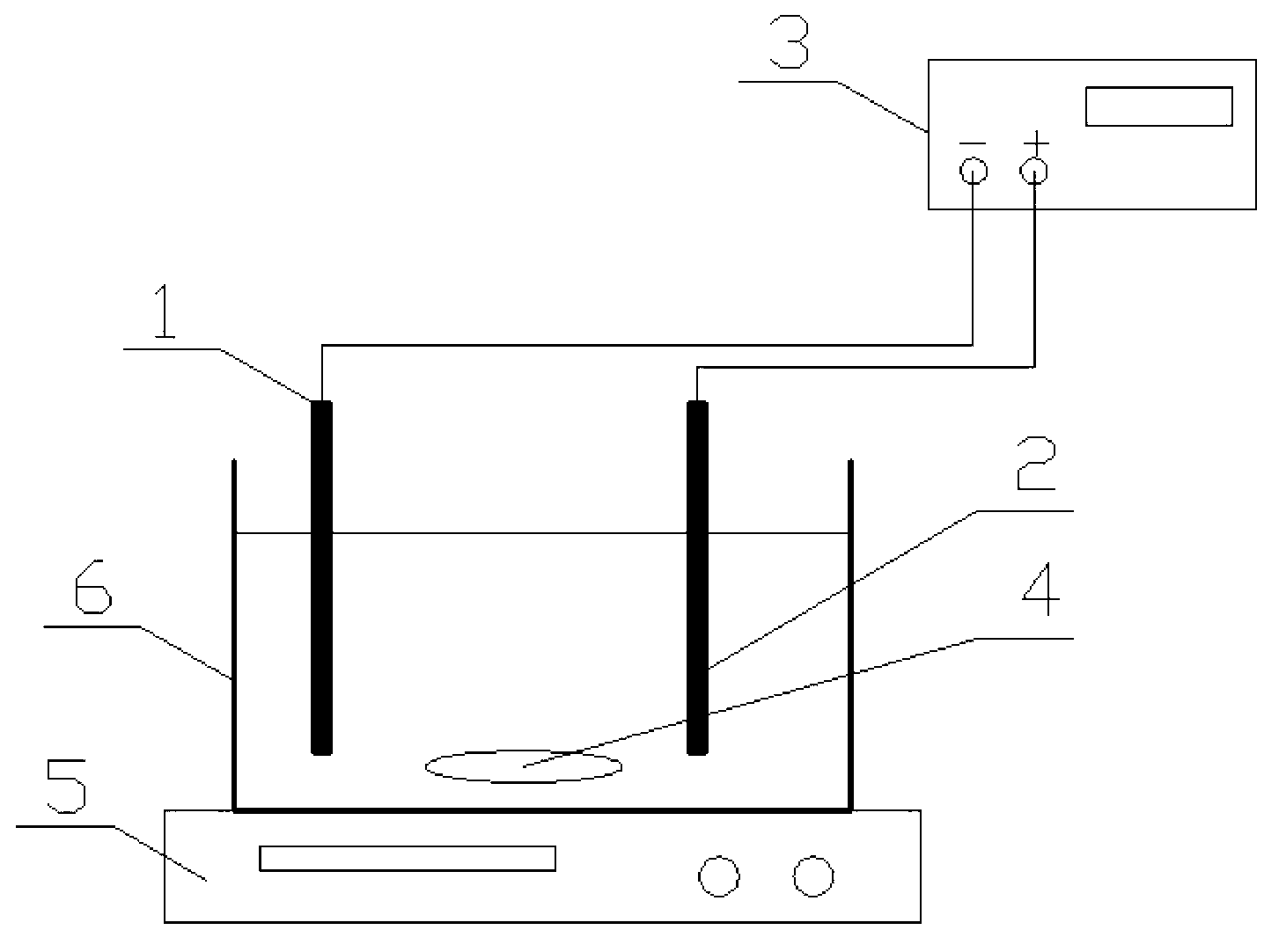

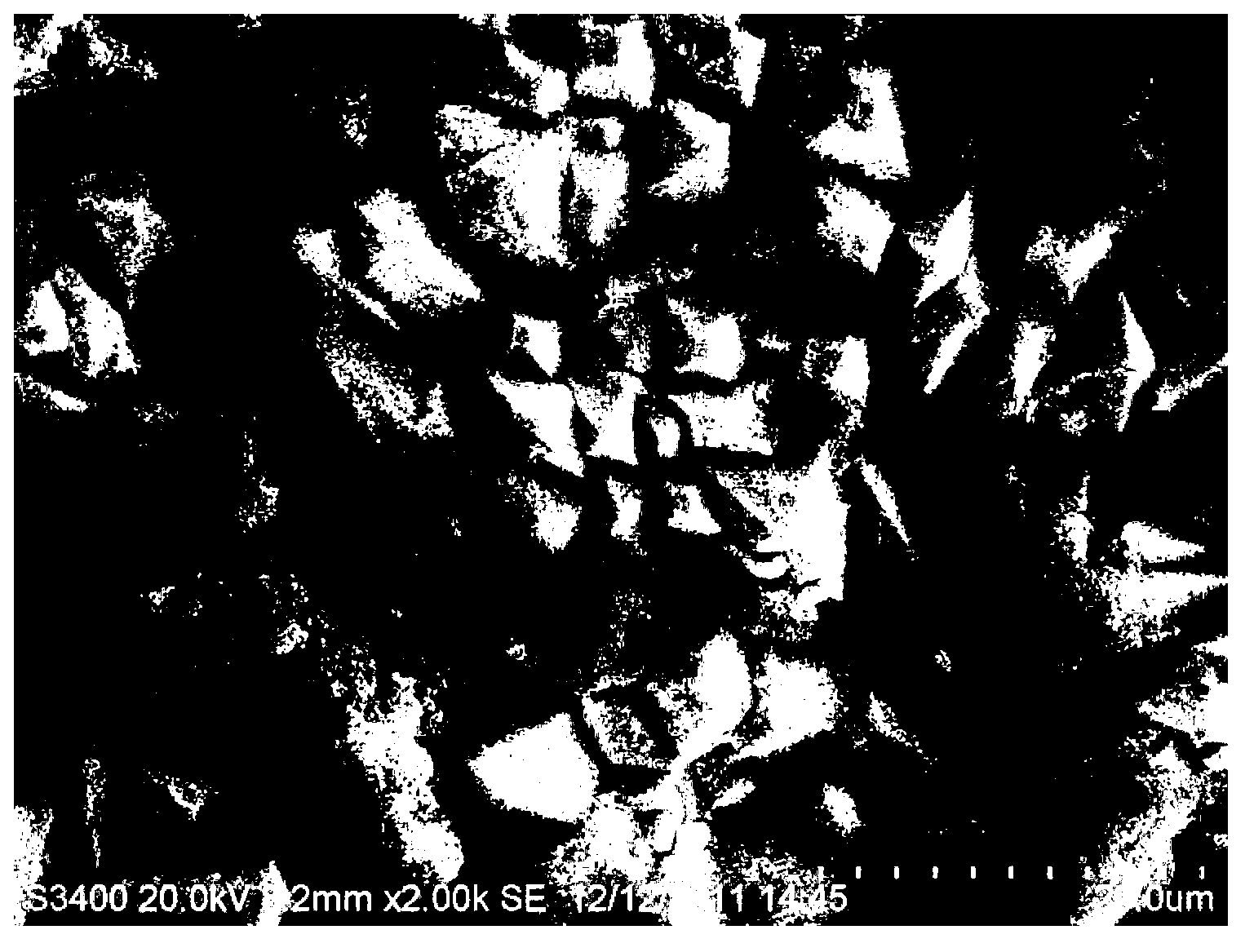

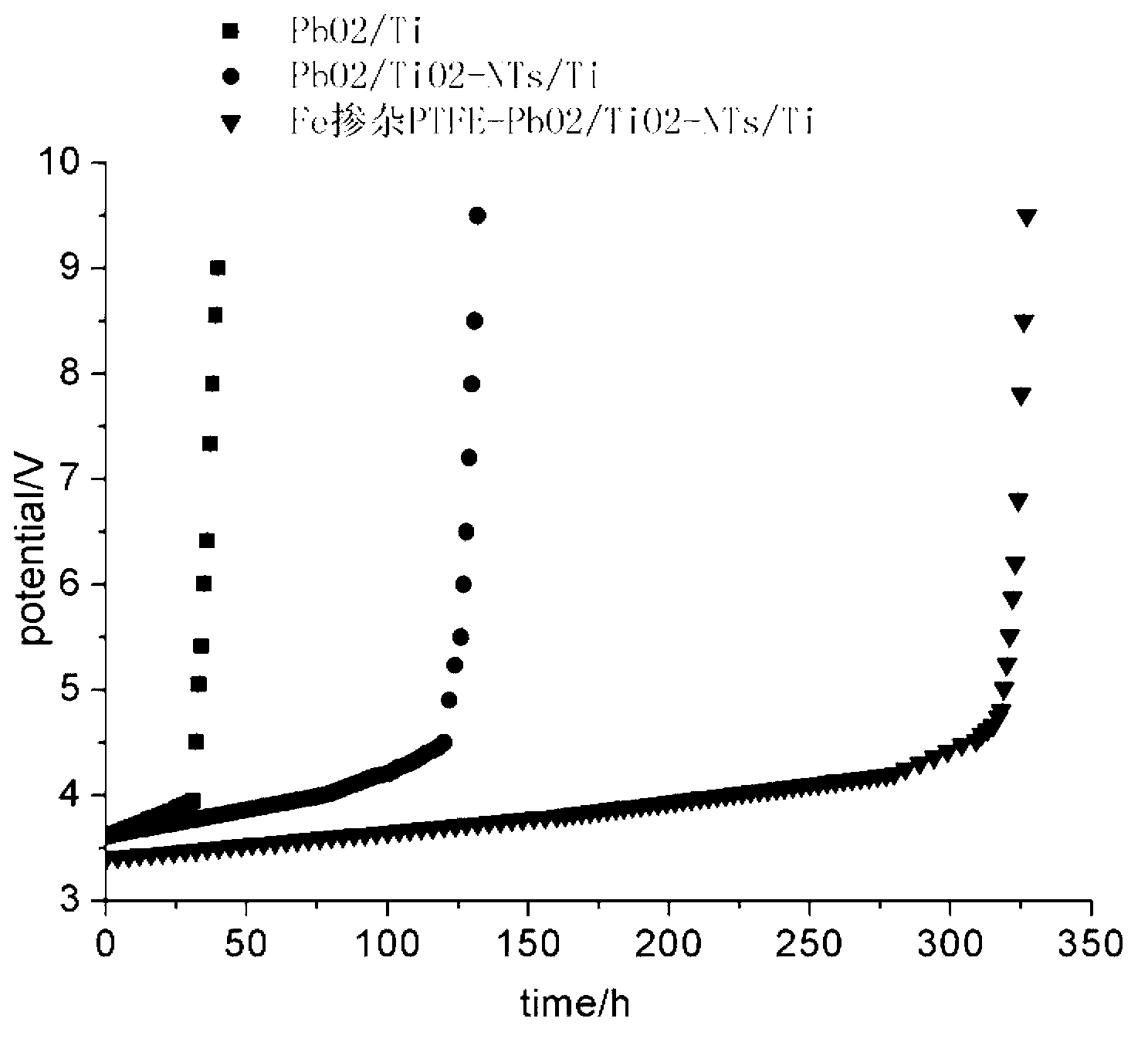

[0035] Example 1 Preparation of Fe-doped PTFE-PbO 2 / TiO 2 -NTs / Ti electrodes:

[0036] Step 1. Cut the titanium plate into a suitable size, and polish the pre-cut titanium plate with 80-mesh, 240-mesh, and 600-mesh sandpaper until silver-white metallic luster appears and the surface of the titanium plate is smooth without scratches.

[0037]Step 2, ultrasonically clean the polished titanium plate in deionized water for 20 minutes, and in absolute ethanol and acetone for 10 minutes each, so as to remove aluminum and sand particles attached during polishing.

[0038] Step 3. Put the cleaned titanium plate in 40% NaOH aqueous solution by mass, heat it in a 95°C water bath to a constant temperature, soak it for 2 hours, take it out and rinse it with distilled water. This process mainly removes the grease on the titanium surface. Rinse the cleaned titanium plate and place it in an aqueous solution of 15% oxalic acid by mass, heat it to a constant temperature in a water bath at 8...

Embodiment 2

[0045] Same as Example 1, only change the current density to 10mA / cm 2 , The removal rate of p-nitrophenol in the treated wastewater was 89.5%.

Embodiment 3

[0047] Same as Example 1, only change the current density to 15mA / cm 2 , The removal rate of p-nitrophenol in the treated wastewater was 94.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com