Production technology of humic acid sustained-release fertilizer

A slow-controlled-release fertilizer and production process technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problem that the application effect is difficult to meet the needs of crop growth, the slow-controlled-release fertilizer has low effective nutrient content, impact resistance and wear resistance. to improve crop quality, improve physical and chemical properties, and increase microbial communities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

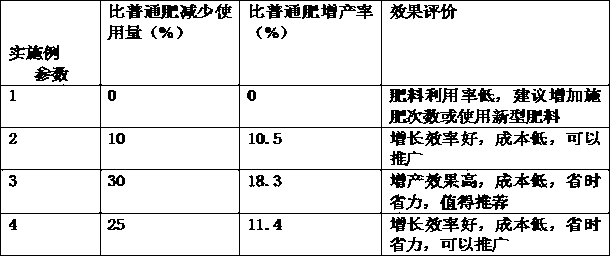

Examples

Embodiment 1

[0017] Mix 20kg of humic acid, 60kg of 0.5-3.5mm urea, 10kg of potassium dihydrogen phosphate, and 10kg of potassium nitrate to make common fertilizer.

Embodiment 2

[0019] Sieve 100kg fertilizer of 0.5-3.5mm urea and transfer it to the blast fluidized bed; spray linseed oil after preheating at 60-70°C, so that the linseed oil is coated on the surface of the continuously rolling fertilizer particles, and gradually wrapped to form a uniform liquid layer. Then spray 0.10-0.35mm weathered coal onto the continuously rolling fertilizer particles, and continue heating to keep the temperature of the material at 60-70°C; under the action of the binder, the weathered coal is wrapped into the moving fertilizer after 10-15 minutes. After the granular fertilizer is applied and solidified, an impact-resistant and wear-resistant coating layer is formed, and the primary coating is completed. Repeat the above operations in order until 5kg of weathered coal is completely wrapped on the fertilizer particles, and the humic acid coated slow-release fertilizer is obtained after the coating layer is cured.

Embodiment 3

[0021] Sieve 0.5-3.5mm urea 100kg fertilizer and transfer it to the blast fluidized bed; spray linseed oil after preheating at 60-70°C, so that the linseed oil is coated on the surface of the continuously rolling fertilizer particles, and gradually wrapped to form a uniform liquid layer. Then spray 0.10-0.35mm weathered coal onto the continuously rolling fertilizer particles, and continue heating to keep the temperature of the material at 60-70°C; under the action of the binder, the weathered coal is wrapped into the moving fertilizer after 10-15 minutes. After the granular fertilizer is applied and solidified, an impact-resistant and wear-resistant coating layer is formed, and the primary coating is completed. Repeat the above operations in order until 8kg of weathered coal is completely wrapped on the fertilizer particles, and the humic acid coated slow-release fertilizer is obtained after the coating layer is solidified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com