Combined process of hydrotreatment-catalytic cracking for residuum

A residual oil hydrogenation and catalytic cracking technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of increasing the load of the residual oil hydrogenation unit, and insufficient utilization of the oil slurry residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

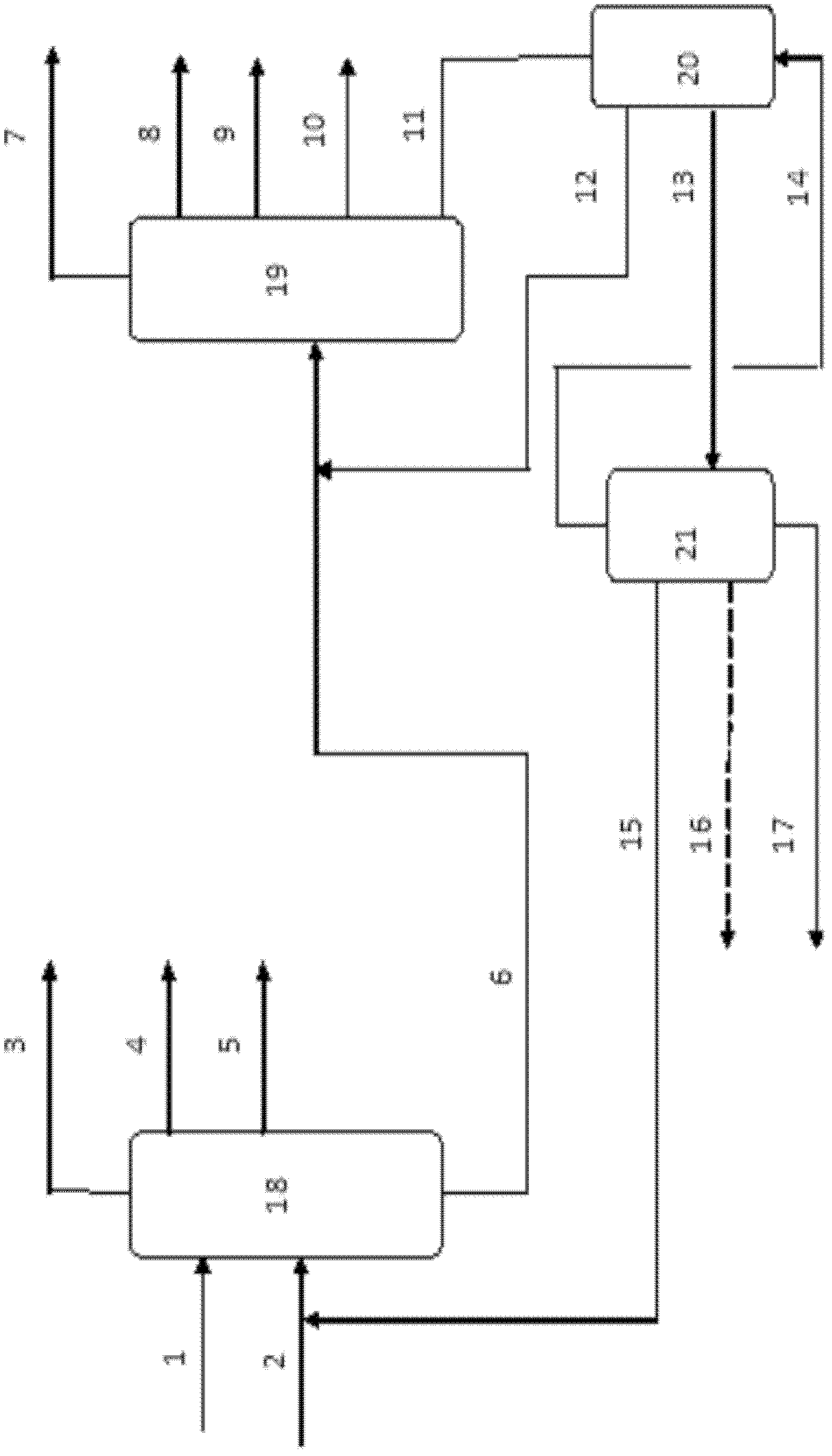

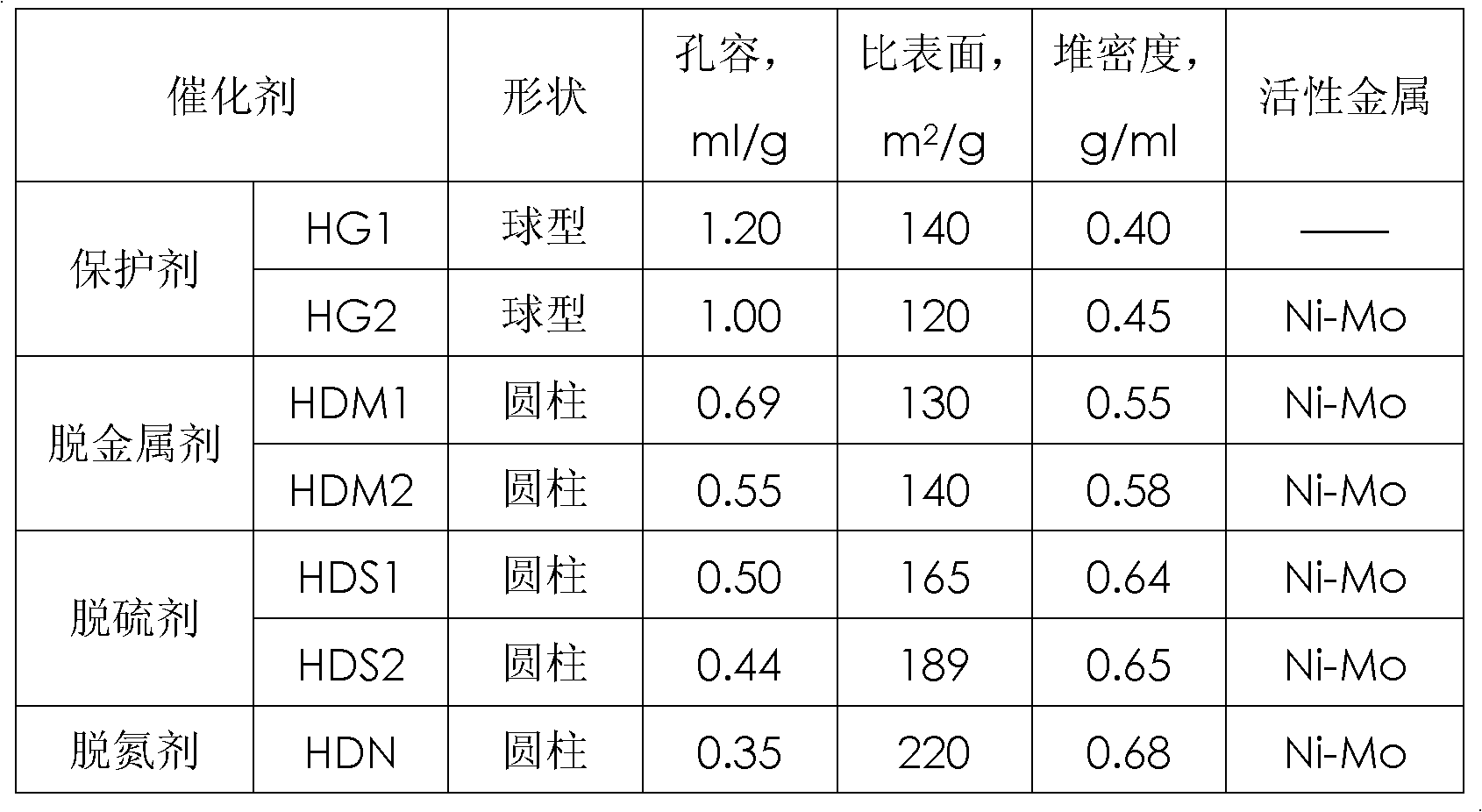

[0024] The residual oil hydrogenation unit used in the examples and comparative examples is a fixed-bed residual oil hydrogenation one-liter four-reactor pilot plant produced by Xytel Corporation of the United States. The device has four reactors in total, which are filled with protective agents, demetallizers, and desulfurization agents respectively. agent and denitrification agent, the properties of the catalyst are shown in Table 1. The gradation ratio is 5:40:30:25, and the catalyst is independently developed by the laboratory. The catalytic cracking test in the embodiment and the comparative example is carried out on the small-scale riser reactor pilot plant that the laboratory designs by itself, and the catalyst used is as shown in table 1.

[0025] Table 1 The present invention uses the main physicochemical property of residual oil hydrogenation catalyst

[0026]

Embodiment 1

[0028] Residue, fractionation tower middle distillate oil (mass composition: 100:9, see Table 2 for properties) and hydrogen are mixed and directly enter the residual oil hydrogenation pilot plant, and react according to the conditions in Table 3, and the reaction products are separated into gas, Hydrogenated naphtha, hydrogenated diesel oil, hydrogenated residual oil, product distribution and operation conditions are shown in Table 4; hydrogenated residual oil and extraction tower raffinate (mass composition is 98:9, properties see Table 2) enter the catalytic In the cracking unit, the products are separated into dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil, catalytic cracking cycle oil and oil slurry. The reaction conditions are shown in Table 3, and the product distribution and operation status are shown in Table 5. The catalytic cracking cycle oil and oil slurry enter the extraction separation tower, the extraction solvent is a mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com