Composite bacteriostatic agent for reducing irritation

A technology of bacteriostatic agent and solution, applied in the field of compound bacteriostatic agent, can solve the problems of poor water solubility of salicylic acid, large skin irritation, application limitation, etc., and achieve the effect of obvious bacteriostatic effect, reducing irritation and realizing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

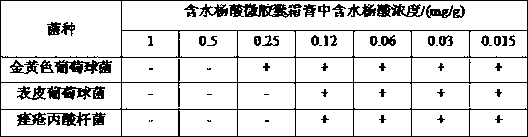

Method used

Image

Examples

Embodiment 1

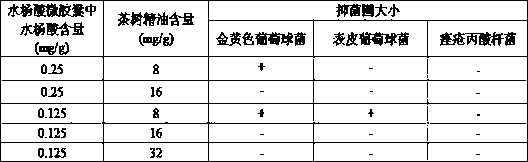

[0020] Accurately weigh 2g of salicylic acid, dissolve it in 50ml of 60% ethanol solution; then accurately weigh 2g of water-soluble chitosan oligosaccharide with a molecular weight of 2000Da~30000Da (purchased in the market), dissolve it in 50ml of water at 60°C; Add the sylic acid ethanol solution into the above chitosan oligosaccharide solution, stir and mix evenly. After the obtained mixed solution is homogenized by the colloid mill, the drying conditions are as follows: the air inlet temperature is 180°C, the tuyere temperature is 80°C, and the feed Quantity is dried under the condition of 8.6ml / min, obtains the oligochitosaccharide / salicylic acid microcapsule of 2.1g, productive rate is 52%, and the loading capacity and inclusion rate of salicylic acid are respectively 19.1% and 21.5%.

[0021] Accurately weigh and prepare according to the ratio of: 0.125 mg salicylic acid, 16 mg tea tree essential oil and 1 g cream, stir and mix well to obtain the compound inhibitor.

Embodiment 2

[0023] Accurately weigh 2g of salicylic acid, dissolve it in 50ml of 20% ethanol solution; then accurately weigh 2g of water-soluble chitosan oligosaccharide with a molecular weight of 2000Da~30000Da (market purchase), dissolve it in 50ml of water at 60°C; Add the sylic acid ethanol solution into the above chitosan oligosaccharide solution, stir and mix evenly. After the obtained mixed solution is homogenized by the colloid mill, the drying conditions are as follows: the air inlet temperature is 190°C, the tuyere temperature is 90°C, and the feed Quantity is dried under the condition of 10.6ml / min, obtains the oligochitosaccharide / salicylic acid microcapsule of 2.2g, productive rate is 55%, and the loading capacity and inclusion rate of salicylic acid are respectively 19.8% and 21.8%.

[0024] Accurately weigh and prepare according to the ratio of: 0.25 mg salicylic acid, 48 mg tea tree essential oil and 1 g cream, stir and mix well to obtain the compound inhibitor.

Embodiment 3

[0026] Accurately weigh 2g of salicylic acid, dissolve it in 50ml of 40% ethanol solution; then accurately weigh 3g of water-soluble chitosan oligosaccharide with a molecular weight of 2000Da~30000Da (purchased in the market), dissolve it in 50ml of water at 60°C; Add the sylic acid ethanol solution into the above chitosan oligosaccharide solution, stir and mix evenly. After the obtained mixed solution is homogenized by the colloid mill, the drying conditions are as follows: the air inlet temperature is 200°C, the tuyere temperature is 80°C, and the feed Quantity is dried under the condition of 13.6ml / min, obtains the oligochitosaccharide / salicylic acid microcapsule of 3.3g, and productive rate is 56%, and the loading capacity and inclusion rate of salicylic acid are respectively 15.3% and 17.7%.

[0027] Accurately weigh and prepare according to the ratio of: 0.375 mg salicylic acid, 32 mg tea tree essential oil and 1 g cream, stir and mix well to obtain the compound inhibitor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com