Column for separating and purifying micromolecular pollutant in food and application method thereof

A technology for small molecules and pollutants, which is applied in the direction of chemical instruments and methods, other chemical processes, and the preparation of test samples. It can solve the problems of labor cost and time-consuming, and achieve simple and labor-saving operation, good purification effect, and convenient use. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Object to be inspected: soy sauce;

[0039] Types of small-molecule food contaminants: urethane, 4 kinds of chloropropanol, acrylamide;

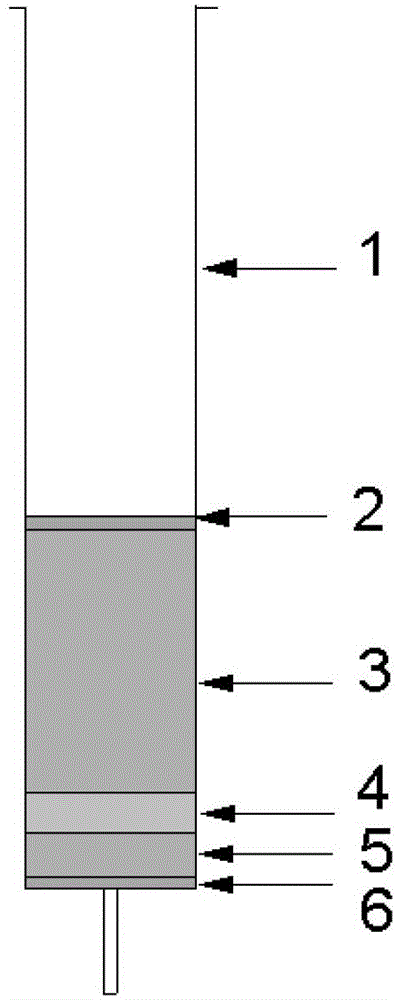

[0040] Purification column packing configuration: packing 2g, of which the upper layer of diatomaceous earth (Extrelut TM NT, Merck Chemical Technology (Shanghai) Company) 1.5g, Amine-based fillers (NH2, Aigel Technology (Tianjin)) 0.2g, lower layer of diatomaceous earth (Extrelut TM NT, Merck Chemical Technology (Shanghai) Company) 0.3g;

[0041] The purification method includes the following steps:

[0042] The first step is to load the sample. Accurately weigh 1g of the well-mixed soy sauce sample and directly add it to the purification column and let it stand for 20 minutes to make the sample liquid fully dispersed and adsorbed in the solid diatomaceous earth filler;

[0043] The second step is to rinse and remove impurities; add 10mL of n-hexane to rinse and discard;

[0044] The third step, elution, eluted with 15ml ethyl acetate: ether=...

Embodiment 2

[0048] Objects to be inspected: mixed meal samples;

[0049] Types of small-molecule food contaminants: urethane, 4 kinds of chloropropanol, acrylamide;

[0050] Purification column packing configuration: packing 5.5g, of which the upper layer of diatomaceous earth (Celite545) 4.5g, the amine-based packing (PSA, Aijieer Technology (Tianjin)) 0.5g, the lower layer of diatomaceous earth (Celite545) 0.5g;

[0051] The purification method includes the following steps:

[0052] The first step is to stir and mix the sample evenly, accurately weigh 0.5g of a well-mixed meal sample, add water-extract 2 times, add 2 mL of water each time;

[0053] The second step is to load the sample. Combine the extracts obtained after the two extractions and add them directly to the purification column, and let it stand for 30 minutes to make the sample liquid fully dispersed and adsorbed in the solid-phase diatomaceous earth filler;

[0054] The second step is to rinse and remove impurities; add 35 mL of n-he...

Embodiment 3

[0059] Objects to be inspected: liquid milk products;

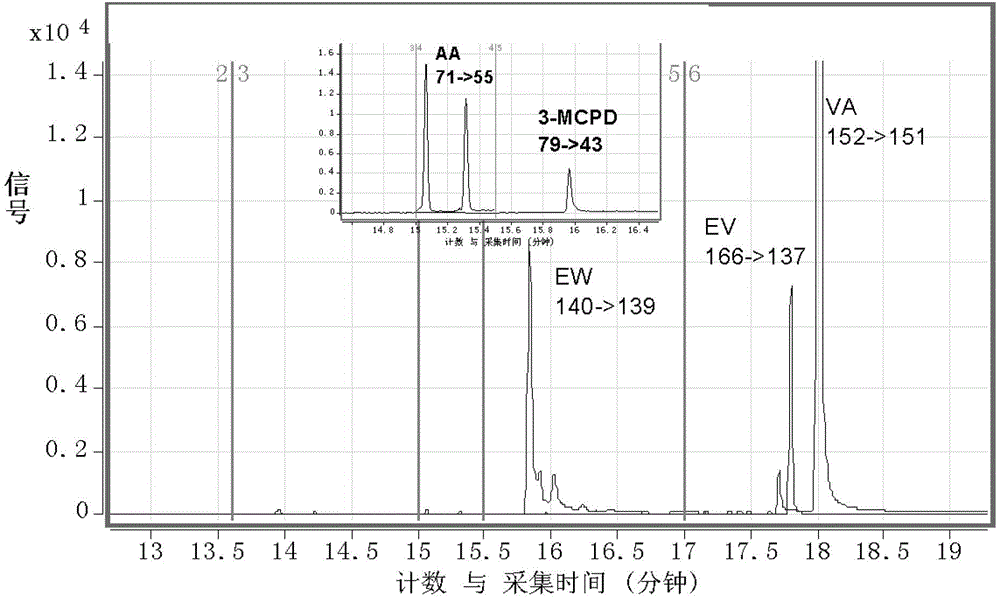

[0060] Types of small-molecule food contaminants: ethyl carbamate, 4 kinds of chloropropanol, acrylamide, 3 kinds of milk flavor (ethyl maltol, vanillin, ethyl vanillin);

[0061] Packing configuration of purification column: same as in Example 1.

[0062] The purification method includes the following steps:

[0063] The first step is to load the sample, accurately weigh 1g of the uniformly mixed liquid milk product sample, directly add it to the purification column, and let it stand for 20 minutes to make the sample liquid fully dispersed and adsorbed in the solid diatomaceous earth filler. The other subsequent steps are the same Example 1;

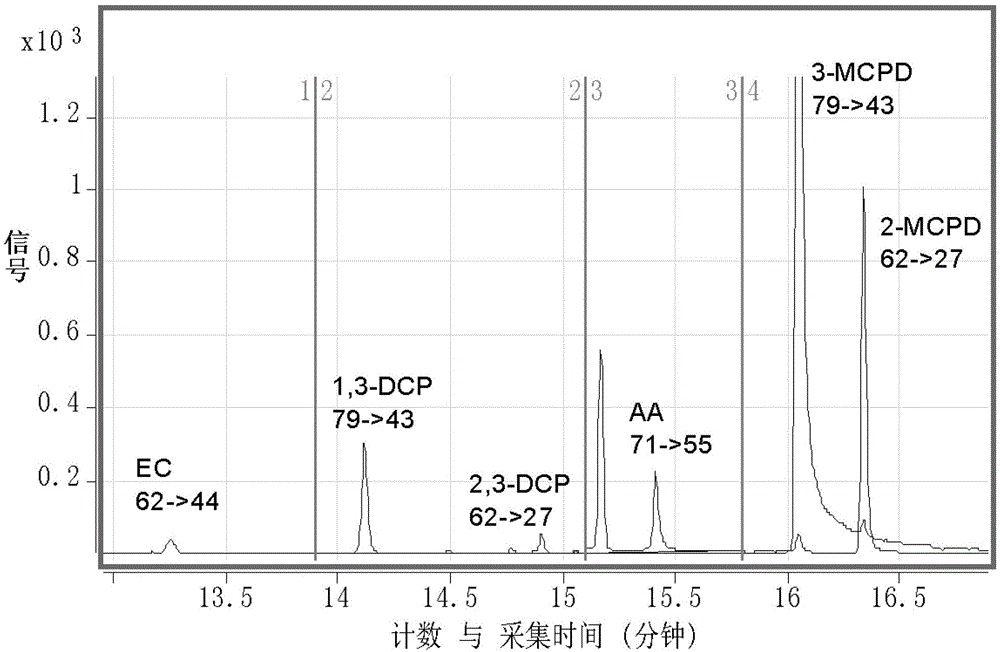

[0064] Analyte recovery rate: The target analytes are 9 small-molecule food contaminants, which are detected by GC-MS / MS. The chromatograms of typical samples are shown in image 3 , Where EC: not detected, 1,3-DCP: not detected, 2,3-DCP: not detected, AA: 6.9μg / kg, 3-MCPD: 5.1μg / kg, 2-MCPD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com