Preparation method of self-assembled silver ball SERS (Surface Enhanced Raman Scattering) base with controllable silver nano sheet thickness

A silver nanosheet, self-assembly technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of inability to provide, complex preparation methods, etc., and achieve the effects of convenient operation, simple reaction conditions, and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0027] (1) Use silver nitrate as the silver source, L-ascorbic acid as the reducing agent, and citric acid as the modifying agent to make aqueous solutions respectively, wherein the ratio of silver nitrate: L-ascorbic acid is 1:1 molar ratio, organic acid: silver nitrate is 0.0025:1 molar ratio, above-mentioned raw material is made into aqueous solution;

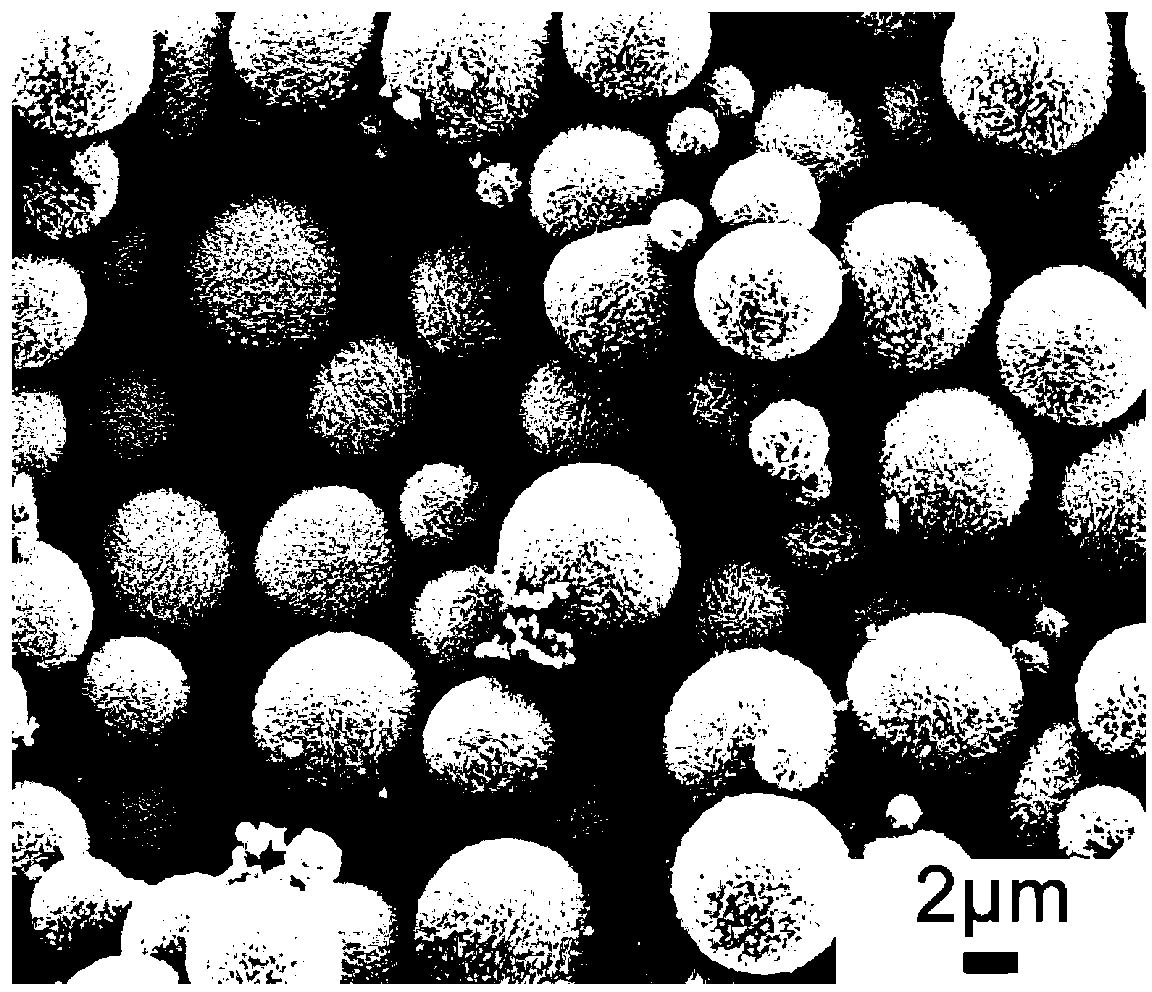

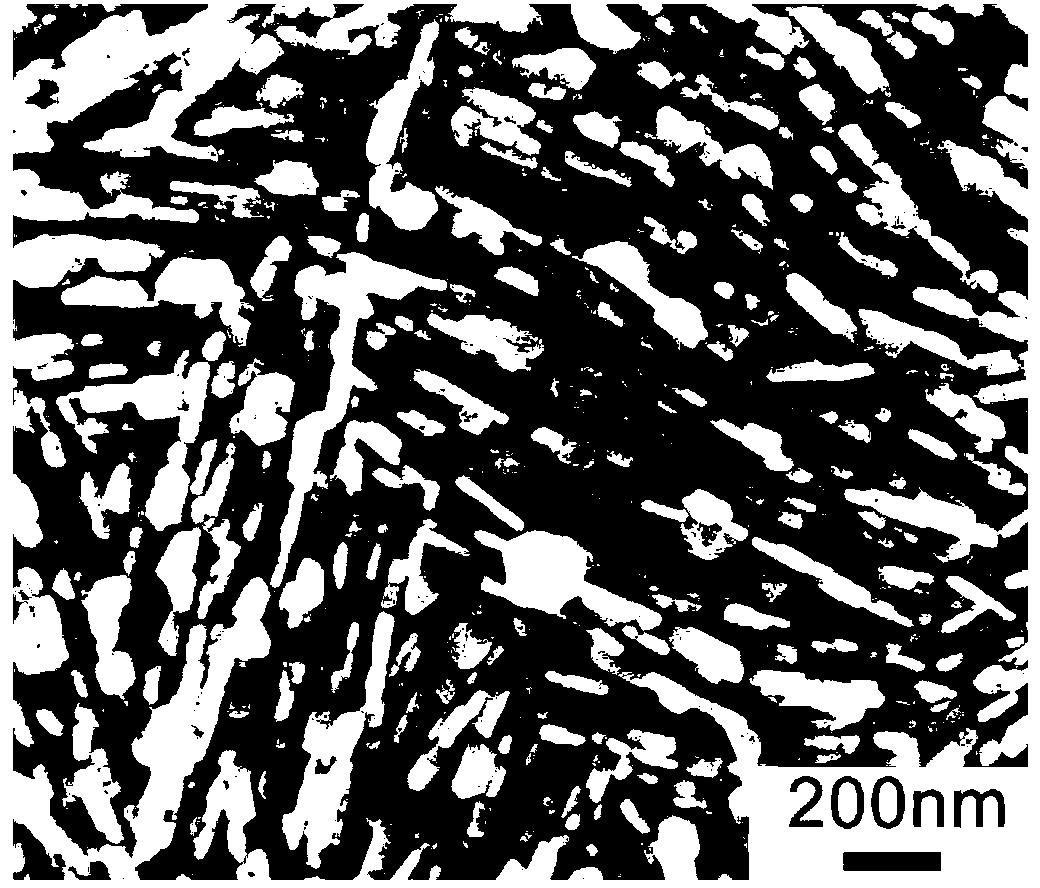

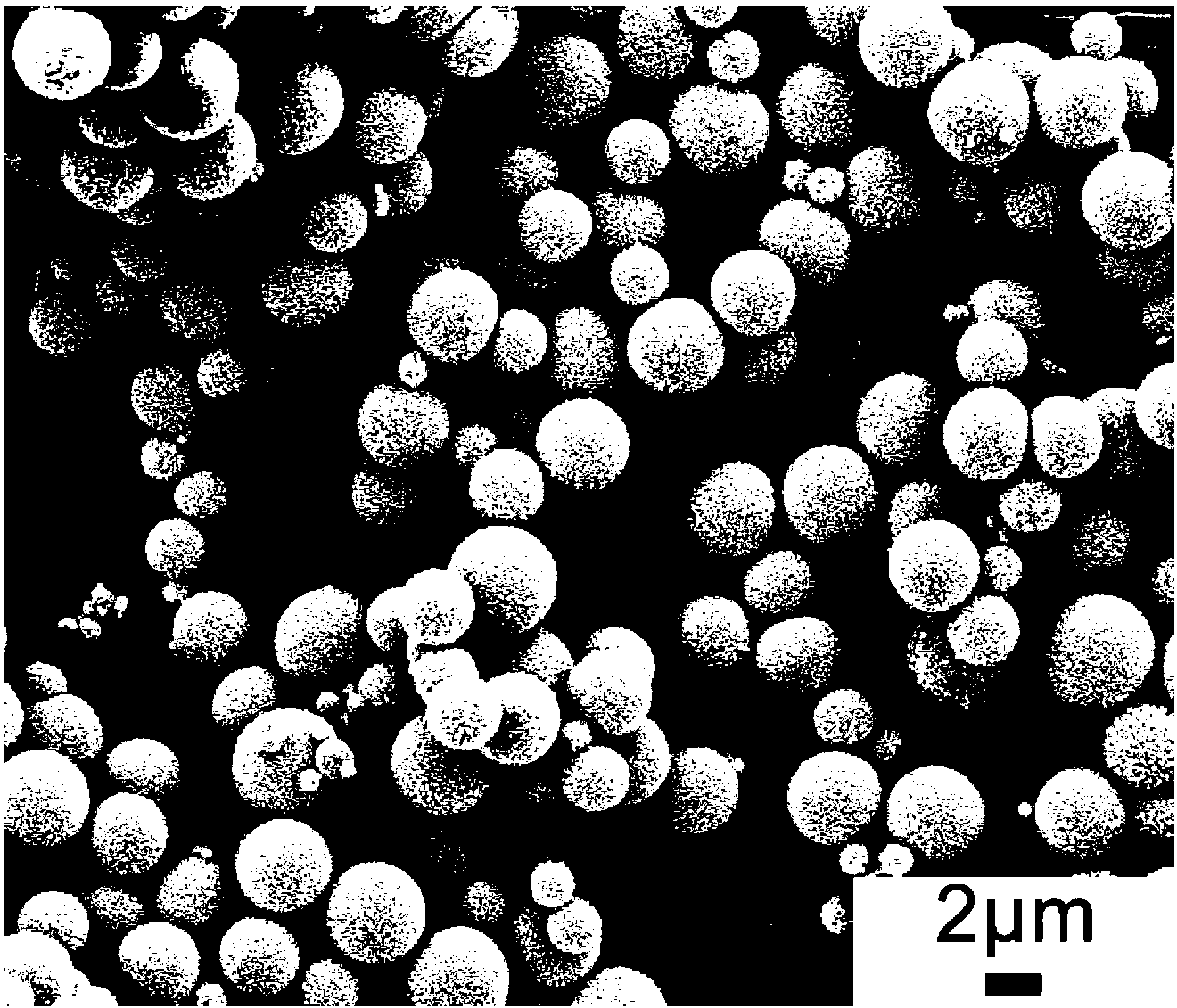

[0028] (2) Add the silver nitrate solution to the water cooled in the ice bath under the condition of stirring, take a small amount of organic acid solution with a micropipette, add it to the silver nitrate solution, stir evenly, and then add the L-ascorbic acid solution once Quickly added to the mixed solution, reacted for 2 minutes under stirring conditions in an ice bath, collected the precipitate, and washed it with deionized water until the pH value reached 7, that is, a self-assembled silver ball SERS substrate with a surface silver nanosheet thickness of 26 nm was obtained . The X-ray diffraction (XRD) pattern of the...

Embodiment approach 2

[0030] (1) Use silver nitrate as the silver source, L-ascorbic acid as the reducing agent, and citric acid as the modifying agent to make aqueous solutions respectively, wherein the ratio of silver nitrate: L-ascorbic acid is 1:1 molar ratio, organic acid: silver nitrate is 0.0075:1 molar ratio, above-mentioned raw material is made into aqueous solution;

[0031] (2) Add the silver nitrate solution to the water cooled in the ice bath under the condition of stirring, take a small amount of organic acid solution with a micropipette, add it to the silver nitrate solution, stir evenly, and then add the L-ascorbic acid solution once Quickly added to the mixed solution, reacted for 7 minutes under stirring conditions in an ice bath, collected the precipitate, and washed it with deionized water until the pH value reached 7, that is, a self-assembled silver ball SERS substrate with a surface silver nanosheet thickness of 41 nm was obtained . Its XRD result is the same as Embodiment 1...

Embodiment approach 3

[0033] (1) Use silver nitrate as the silver source, L-ascorbic acid as the reducing agent, and citric acid as the modifying agent to make aqueous solutions respectively, wherein the ratio of silver nitrate: L-ascorbic acid is 1:1 molar ratio, organic acid: silver nitrate is 0.01-0.025:1 molar ratio, making the above raw materials into an aqueous solution;

[0034] (2) Add the silver nitrate solution to the water cooled in the ice bath under the condition of stirring, take a small amount of organic acid solution with a micropipette, add it to the silver nitrate solution, stir evenly, and then add the L-ascorbic acid solution once Quickly added to the mixed solution, reacted for 10 minutes under stirring conditions in an ice bath, collected the precipitate, and washed it with deionized water until the pH value reached 7, that is, a self-assembled silver ball SERS substrate with a thickness of 57 nm of silver nanosheets on the surface was obtained. Its XRD result is the same as E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com