Production method of industrial sodium sulphide and equipment adopted in production method

A production method and technology of production equipment, applied in the field of industrial sodium sulfide production, can solve the problems of high labor intensity, low production efficiency, methods and equipment not adopted, etc., and achieve the effect of great development significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

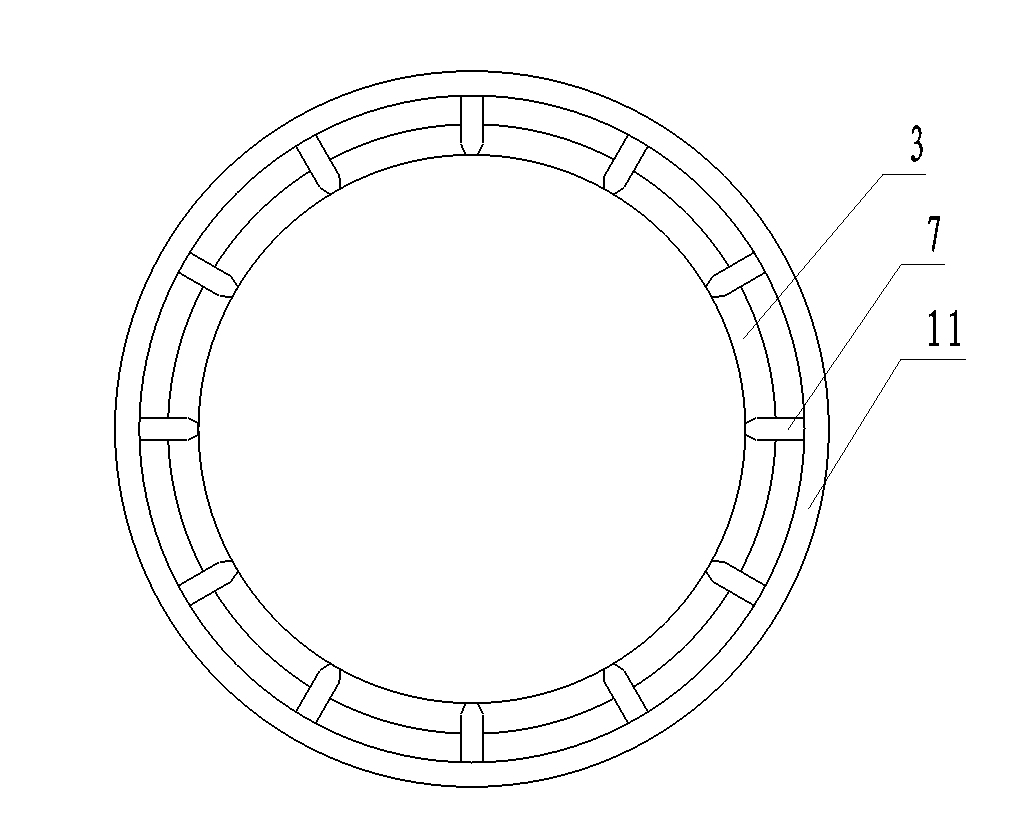

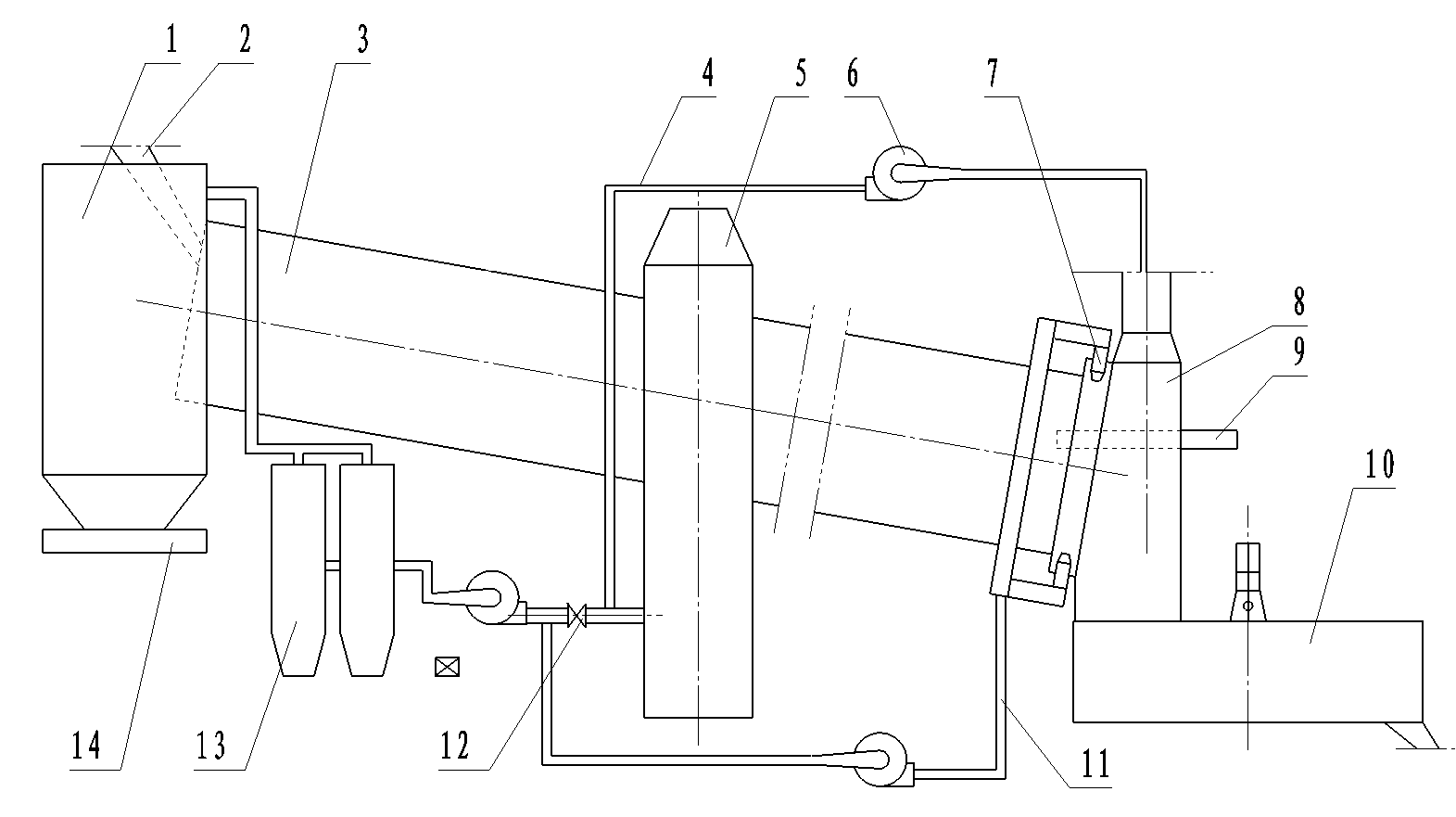

[0020] Example 1: refer to Figure 1~2 , the long converter is provided with two-stage dedusting, i.e. a centrifugal deduster 13 and a desulfurization deduster 5 two-stage dedusting, a gas nozzle 7 is provided at the end of the discharge port of the long converter body 3, and the gas nozzle 7 is provided with a plurality of And it is arranged around the edge of the furnace body 3 at the outlet of the furnace body 3. The nozzle of the gas nozzle 7 is directed to the center of the furnace body 3 in a radial direction. 1. To collect the high-temperature flue gas or dust discharged from the furnace body at about 300°C. After the primary dust removal by the centrifugal dust collector 13, a part is intercepted and transported by the fan and the gas delivery pipe 11 to the outlet end of the furnace head and sprayed by the gas nozzle 7. , the injection pressure should be controlled at 0.15~1Mpa, and the injected flue gas forms an air curtain barrier at the burner head to block the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com