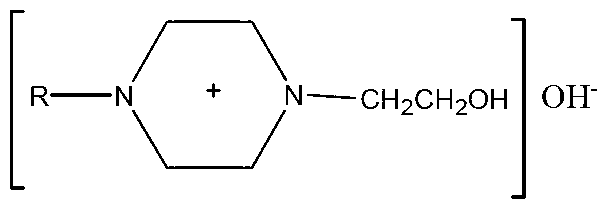

Caprolactam basic ionic liquid as well as preparation method and application thereof

A caprolactam, basic ion technology, applied in liquid carbon-containing fuels, chemical instruments and methods, fatty acid esterification, etc., can solve the problem of low activity of biodiesel, achieve strong alkalinity, mild reaction conditions and simple synthesis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

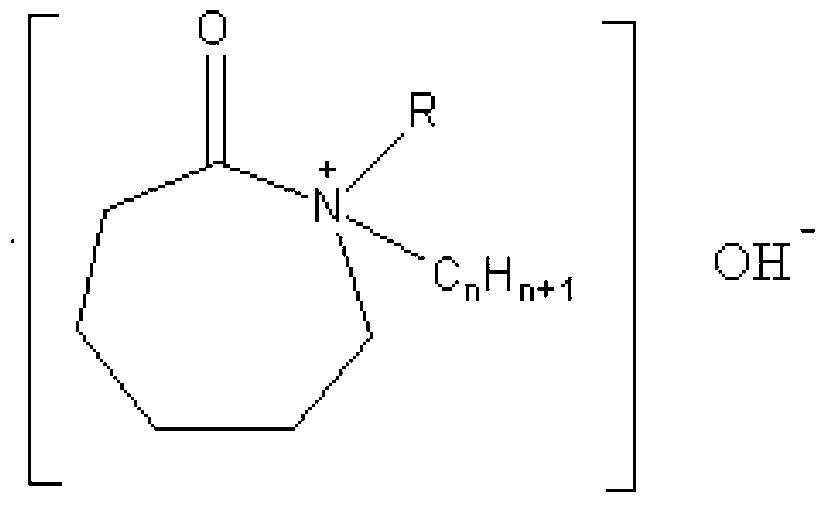

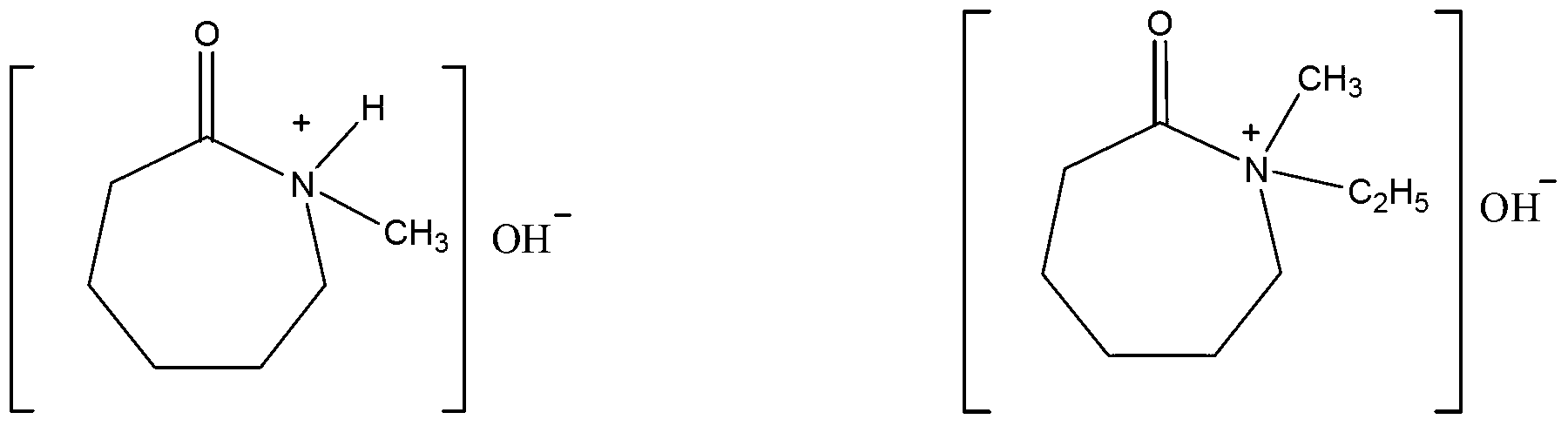

Embodiment 1

[0043] Weigh 10g of N-methyl caprolactam, dissolve it in ethanol solvent and put it into a four-necked flask. The amount of ethanol is 10% of the mass of N-methyl caprolactam. In the constant pressure separatory funnel, the molar ratio of N-methyl caprolactam and bromo-n-butane is 1:0.8, and the dripping speed is controlled to slowly drip into the flask, and N 2 , insert a condenser tube, a thermometer, turn on stirring, take out a constant pressure separatory funnel after the dropwise addition and continue to stir and react for 4 hours. After the reaction is completed, pour out the unreacted solution of the upper layer, wash the intermediate with ethyl acetate for several times, rotate it to evaporate, put it in Dry to constant weight in a vacuum drying oven at 70°C to obtain an intermediate with higher purity. Weigh the intermediate in a three-necked flask, add solvent methanol to make a solution, the volume-to-mass ratio of the added methanol and the intermediate is 1 mL / g,...

Embodiment 2

[0045] Weigh 10 g of caprolactam, dissolve it in acetonitrile solvent, put it into a four-necked flask, and the amount of acetonitrile is 50% of the mass of caprolactam. The molar ratio to methyl bromide is 1:2, and the dripping speed is controlled to slowly drip into the flask, and N is fed at the same time. 2 , insert a condenser tube, a thermometer, turn on stirring, take out a constant pressure separatory funnel after the dropwise addition and continue to stir for 12 hours, pour out the unreacted solution of the upper layer after the reaction, wash the intermediate with ethyl acetate several times, rotate it evaporate, put it in Dry to constant weight in a vacuum drying oven at 70°C to obtain an intermediate with higher purity. Weigh the intermediate in a three-necked flask, add solvent methanol to make a solution, the volume-to-mass ratio of the methanol added to the intermediate is 4 mL / g, and then weigh the methanol solution of NaOH, where the volume-to-mass ratio of me...

Embodiment 3

[0047] Weigh 10g of N-ethyl caprolactam, dissolve it in acetonitrile solvent, put it into a four-necked flask, the amount of acetonitrile is 30% of the mass of caprolactam, place it in an oil bath and heat it up to 110 ° C, weigh bromo-n-butane in a constant pressure fraction. In the liquid funnel, the molar ratio of N-ethyl caprolactam and bromo-butane is 1:1, and the dripping speed is controlled to slowly drop into the flask, while feeding N 2 , insert a condenser tube, a thermometer, turn on stirring, take out a constant pressure separatory funnel after the dropwise addition and continue to stir and react for 8 hours, pour out the unreacted solution of the upper layer after the reaction is completed, wash the intermediate with ethyl acetate for several times, rotary evaporation, put in Dry to constant weight in a vacuum drying oven at 70°C to obtain an intermediate with higher purity. Weigh the intermediate in a three-necked flask, add solvent methanol to make a solution, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com