Environmental-friendly synthesis method of fluorescent carbon dot with up-down conversion function

A technology of fluorescent carbon dots and synthesis methods, which is applied in the directions of fluorescence/phosphorescence, chemical instruments and methods, nano-carbon, etc., can solve the problems of carbon dots without up-conversion properties, complicated operation, poor luminescence stability of carbon dots, etc., and achieves synthesis Mild and controllable conditions, high fluorescence quantum yield, and strong photobleaching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

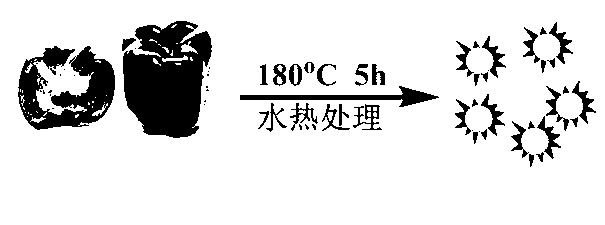

[0035] A method for preparing fluorescent carbon dots with excellent performance, including the following operation process, the synthetic route diagram is shown in figure 1 :

[0036] Edible red pepper is used as carbon source, and water is used as solvent. Add 1 g of water to 4 g of washed fresh pepper flakes, mix evenly, transfer to a 25 mL hydrothermal kettle, and heat at 180 °C for 5 h. After cooling to room temperature, large impurities were discarded to obtain a brown mixture, and the supernatant was collected after centrifugation at 13 krpm for 15 min. The supernatant was dialyzed for 24 hours with a cut-off of 3500 dialysis bags, and the dialysate was collected.

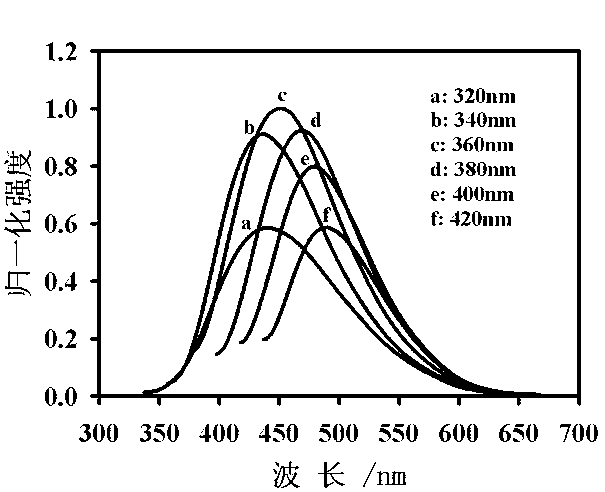

[0037] The prepared carbon dots were dispersed in deionized water to obtain fluorescent carbon dots with up- and down-conversion properties with emission wavelengths in the range of 400nm-600nm and a quantum yield of 19.2%.

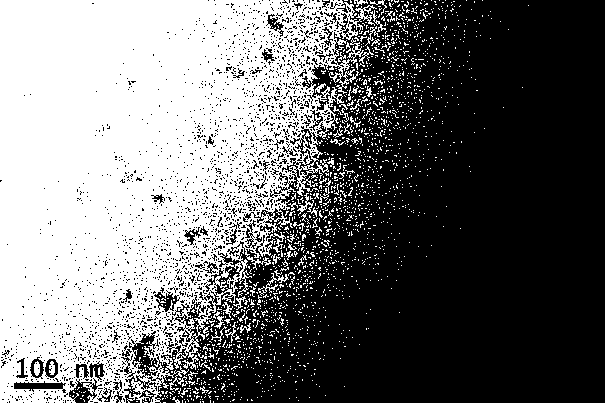

[0038] figure 2 Transmission electron micrographs of the stable fluorescent c...

Embodiment 2

[0041] Ripe edible red pepper is used as carbon source, and water is used as solvent. Take 4g of washed peppers, chop them into pieces, add 1g of water, seal them in a hydrothermal kettle, and heat them at 180°C for 2h.

[0042] After the reaction, take out the still to cool to room temperature, filter out large particles, get the mixture and centrifuge at 13krpm to remove larger particles, and transfer the supernatant to a beaker. The supernatant was dialyzed for 24 hours with a cut-off of 3500 dialysis bags, and the dialysate was collected. Its fluorescence quantum yield is 14.8%.

Embodiment 3

[0044] Ripe edible red pepper is used as carbon source, and water is used as solvent. Take 4g of washed peppers, cut them into pieces, add 1g of water, seal them in a hydrothermal kettle, and heat them at 140°C for 5h.

[0045] After the reaction, take out the still to cool to room temperature, filter out large particles, get the mixture and centrifuge at 13krpm to remove larger particles, and transfer the supernatant to a beaker. The supernatant was dialyzed for 24 hours with a cut-off of 3500 dialysis bags, and the dialysate was collected. Its fluorescence quantum yield is 15.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com