Method for innocent treatment and resource utilization of industry byproduct waste salt slag

A technology for harmless treatment and industrial by-products, applied in combustion methods, incinerators, lighting and heating equipment, etc. Simple and easy process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

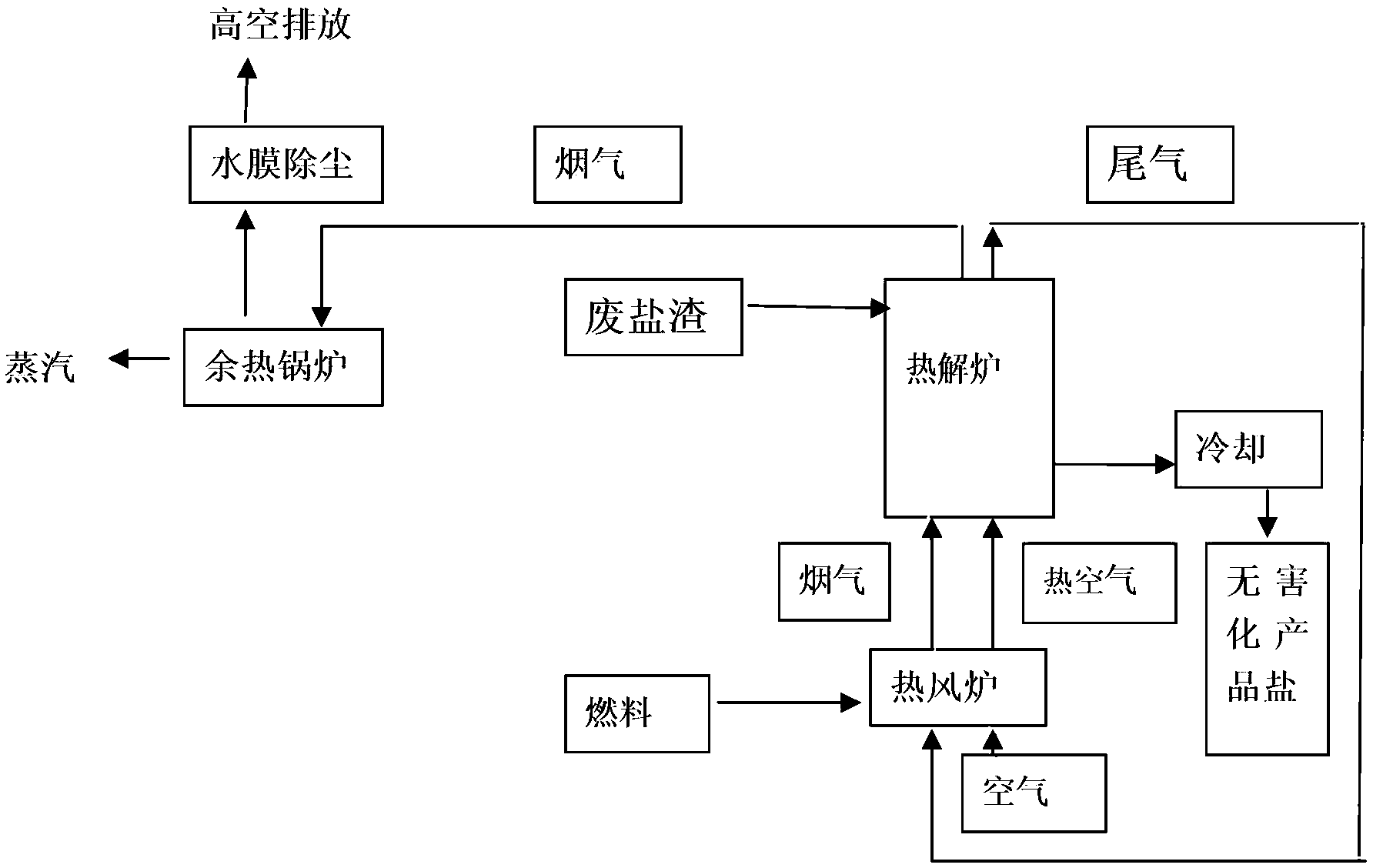

Method used

Image

Examples

Embodiment 1

[0014] Harmless treatment of hydrazine hydrate by-product sodium chloride waste salt residue.

[0015] The COD value of hydrazine hydrate by-product sodium chloride waste salt slag (make the salt into a 20% aqueous solution and test the COD value of the solution) is 5700ppm.

[0016] The flue gas heated to 500-700°C by the hot blast stove is passed into the pipe in the pyrolysis furnace, so that the temperature of the pyrolysis furnace is stabilized at 300-500°C, and then the dried hydrazine hydrate by-product sodium chloride waste salt slag is continuously Add the top disc of the pyrolysis furnace from the top of the pyrolysis furnace, the material moves from top to bottom, and the residence time is 4-7 hours. The tail gas from the pyrolysis furnace returns to the hot blast stove through the tail gas pipe for use, The heated flue gas coming out of the heating pipe enters the waste heat boiler to generate steam for utilization. The flue gas is discharged at high altitude after...

Embodiment 2

[0020] Harmless treatment of waste salt residue of sodium chloride by-product of glyphosate.

[0021] The COD value of the waste salt slag of sodium chloride, a by-product of glyphosate (make the salt into a 20% aqueous solution, and test the COD value of the solution) is 12000ppm.

[0022] The flue gas heated to 600-900°C by the hot blast stove is passed into the pipe in the pyrolysis furnace to stabilize the temperature of the pyrolysis furnace at 400-600°C, and then the dried glyphosate by-product sodium chloride waste salt slag Continuously add the uppermost disc of the pyrolysis furnace from the top of the pyrolysis furnace, the material moves from top to bottom, and the residence time is 4-8 hours. The tail gas from the pyrolysis furnace returns to the hot blast stove for use through the tail gas pipe. The heated flue gas coming out of the furnace heating pipe enters the waste heat boiler to generate steam for utilization. The flue gas is discharged at high altitude afte...

Embodiment 3

[0026] Harmless treatment of metalaxyl by-product sodium chloride waste salt residue.

[0027] The measured COD value of metalaxyl by-product sodium chloride waste salt slag (make the salt into a 20% aqueous solution and test the COD value of the solution) is 7800ppm.

[0028] Pass the flue gas heated to 650-1000°C by the hot blast stove into the pipe in the pyrolysis furnace to stabilize the temperature of the pyrolysis furnace at 350-600°C, and then the dried metalaxyl by-product sodium chloride waste salt slag Continuously add the uppermost disc of the pyrolysis furnace from the top of the pyrolysis furnace, the material moves from top to bottom, and the residence time is 6-10 hours. The heated flue gas coming out of the furnace heating pipe enters the waste heat boiler to generate steam for utilization. The flue gas is discharged at high altitude after being dedusted by the water film. The pyrolyzed salt is discharged from the bottom of the pyrolysis furnace and becomes a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com