Preparation method of superparamagnetic Fe3O4 microspheres

A superparamagnetic, microsphere technology, applied in ferrous oxides, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of unfavorable large-scale industrial production, high pressure, and high requirements for reaction equipment. problem, to achieve the effect of short reaction time, simple steps and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

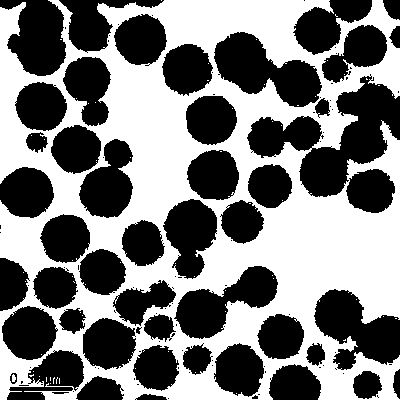

Embodiment 1

[0025] Use 3-aminopropanol and ethylene glycol as a solvent in a ratio of 1 mL:14 mL, add 0.16 g of anhydrous ferric chloride and 0.14 g of polyacrylic acid with an average molecular weight of 1800, dissolve to form a clear solution, and transfer to high pressure In the reaction kettle, keep the temperature at 200 °C for 6 h, cool with the furnace, add 15 mL of absolute ethanol, precipitate for 10 min, pour off the supernatant, the fixed product has good magnetic response, wash with water 3 times, and dry at 60 °C Superparamagnetic Fe 3 o 4 Microspheres. Electron microscope photos such as figure 1 As shown, the average particle size of the microspheres is 362 nm, the average particle size of the particles composing the microspheres is 3.7 nm, and the saturation magnetization curve at room temperature is shown as Figure 5 Middle curve 1.

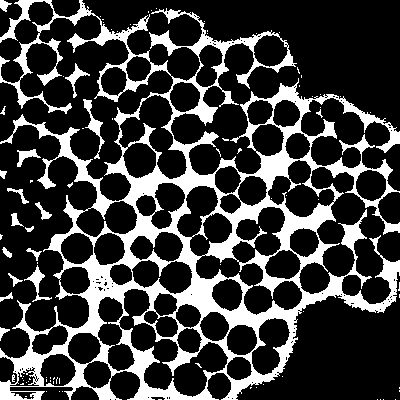

Embodiment 2

[0027] Method is changed into 5mL:10 mL with the ratio of embodiment 1,3-aminopropanol and ethylene glycol, and the electron micrograph of gained product is as follows figure 2 As shown, the average particle size of the microspheres is 240 nm, and the average particle size of the particles composing the microspheres is 6.3 nm.

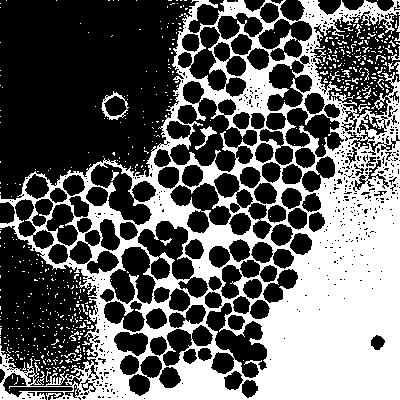

Embodiment 3

[0029] Method is changed into 10mL:5 mL with the ratio of embodiment 1,3-aminopropanol and ethylene glycol, and the electron micrograph of gained product is as follows image 3 As shown, the average particle size of the microspheres is 153 nm, and the average particle size of the particles composing the microspheres is 11.7 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com