Synthetic method for tri-functionality water-soluble epoxy resin

A technology of epoxy resin and synthesis method, which is applied in the field of synthesis of water-soluble epoxy resin, can solve the problems of low epoxy value of liquid epoxy resin, not water-based epoxy resin, large amount of waste water, etc., and achieve environmental pollution, The effect of low epoxy equivalent and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 69.1g (.75mol) of glycerol into a four-necked flask, raise the temperature to 57°C, add 0.7g of catalyst (0.3g of boron trifluoride and 0.4g of titanium tetrachloride), and slowly add 208.2g of epoxy resin dropwise under stirring. Chloropropane, drop it in 4 hours, and react for 3 hours after the drop. Add 150g of absolute ethanol, raise the temperature to 30°C, stir to dissolve, take 60g of NaOH and add it to the reaction bottle six times, add once every half an hour, react for 4 hours after the addition, let stand for 8 hours, filter with suction, and use 20g NaOH Wash with water and ethanol, combine the filtrates, distill under reduced pressure, and remove residual NaCl by suction filtration to obtain a trifunctional water-soluble epoxy resin, which is soluble in water and can be diluted with water in any proportion. According to GB4612-84, the prepared epoxy resin has an epoxy equivalent of 87, that is, an epoxy value of 1.15.

Embodiment 2-4

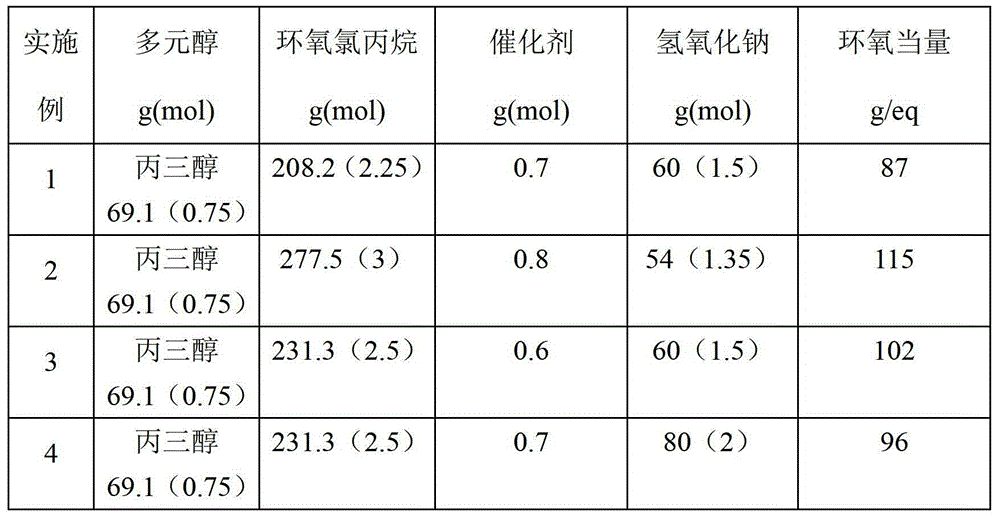

[0027] Adopt different formulas, operating method is identical with embodiment 1, the formula of each embodiment and the property of the waterborne epoxy resin that makes are shown in Table 1:

[0028] Table 1

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com