Preparation method and application of organosilicon photo-diffusion particle

A technology of light diffusing particles and silicone, applied in optics, optical components, instruments, etc., can solve the problems of firm bonding of acrylic glue, aggregation of white spot defects, etc., and achieve the effect of high optical efficiency and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of Silicone Light Diffusing Particles

[0041] 1. Material:

[0042] 1) Methacryloxypropyltrimethoxysilane

[0043] 2) Methyltrimethoxysilane

[0044] 3) Deionized water

[0045] 4) Acid: Strong acids such as hydrochloric acid and sulfuric acid

[0046] 5) Alkali: lithium hydroxide, sodium hydroxide, potassium hydroxide, ammonia water, etc.

[0047] 2. Production method:

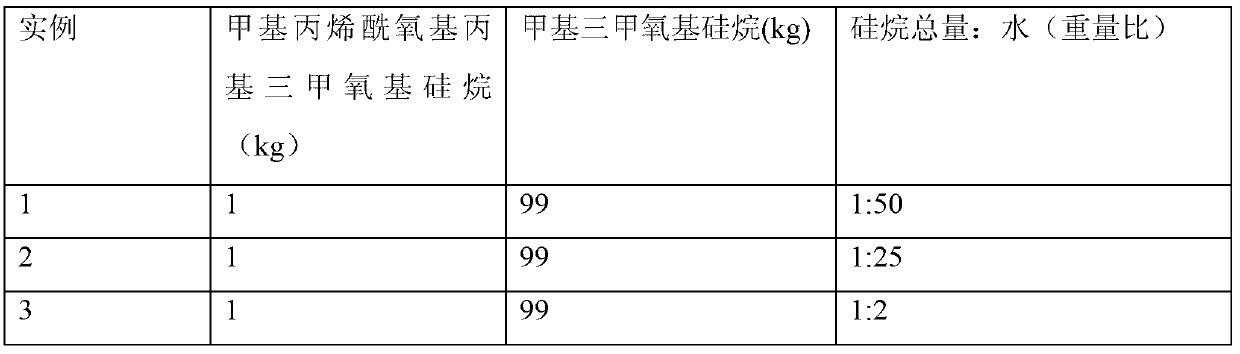

[0048] 1) Methacryloxypropyltrimethoxysilane:methyltrimethoxysilane=1:99–20:80

[0049] 2) (methacryloxypropyltrimethoxysilane+methyltrimethoxysilane): deionized water=1:50–1:2

[0050] 3) Acid: Appropriate amount

[0051] 4) Alkali: appropriate amount

[0052] 5) Add the mixture of methacryloxypropyltrimethoxysilane and methyltrimethoxysilane in proportion to deionized water, add acid until the pH value is 5-6 and stir until the system is completely transparent

[0053] 6) Add alkali until the pH value is 10-12, stop stirring for 3-5 minutes, and stand still for 4-5 hours, or inc...

Embodiment 2

[0058] Embodiment 2 dispersion test

[0059] Mix the silicone light-diffusing particles prepared according to Examples 1-6 in Example 1 and butyl acetate solvent in a weight ratio of 1:3, then add acrylic glue with a solvent weight of 1 / 3, and stir for 120 minutes with a paddle stirrer , coated on PET film and dried, observed under a microscope whether agglomeration occurs.

[0060] Comparative test: non-polar light diffusing particles EL500 (Yongqi material)

[0061] Results The organic silicon light-diffusing particles of the present invention did not agglomerate, while the comparative non-polar light-diffusing particles had at least 10 white spots agglomerated per 100 square centimeters.

[0062] In each example, methacryloxypropyltrimethoxysilane is respectively made of methacryloxypropyltriethoxysilane, glycidyloxypropyltrimethoxysilane, glycidyloxypropyltrimethoxysilane Ethoxysilane, Acryloxypropyltrimethoxysilane, Acryloxypropyltriethoxysilane, Chloropropyltrimethoxys...

Embodiment 3

[0063] The preparation of embodiment 3 light diffusion film

[0064] 1. Materials used:

[0065] i. Light diffusing particles

[0066] ii. Coating resin: acrylic resin

[0067] iii. Curing agent: isocyanate curing agent

[0068] iv. Substrate film: optical grade PET film, thickness 100um

[0069] v. Solvent: butyl acetate

[0070] 2. Equipment used:

[0071] vi. Coating roller

[0072] vii. Circulating Dryer

[0073] 3. Production method:

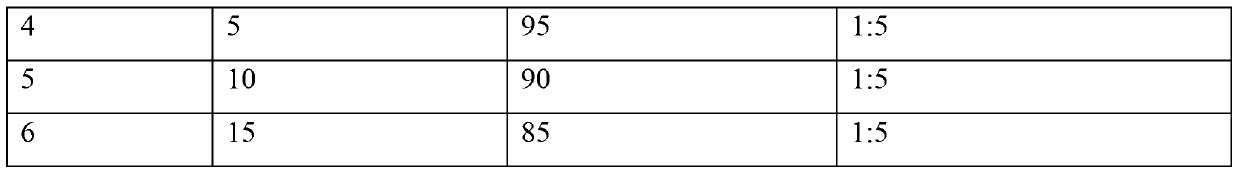

[0074] viii. Add 40-170 grams of light-diffusing particles prepared by each example in Example 1 to 400 grams of solvent, and stir for more than 2 hours until the light-diffusing particles are evenly dispersed in the solvent

[0075] ix. Add 40-100 grams of coating resin and curing agent to the above mixture i, stir well

[0076] x. Use a coating roller to evenly coat ii on the substrate film

[0077] xi. Dry with a circulating dryer at 80-100°C for 3 minutes.

[0078] Haze testing instrument: Shanghai Jingke light transmittance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com