Method for preparation of ketoxime compound and method for preparation of alkoxy-mine hydrochloride

A ketone compound and compound technology are applied in the field of preparation of ketoxime compounds, which can solve the problems of low conversion rate of ketoxime compounds, short service life of catalysts, low conversion rate of ketone compounds, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

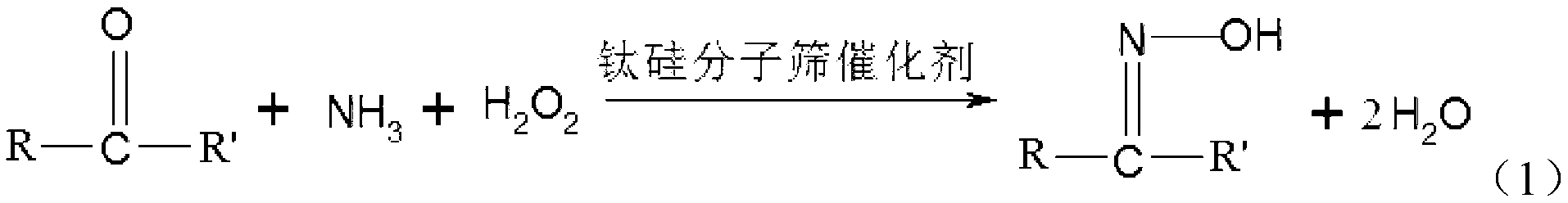

[0027] According to the first aspect of the present invention, the present invention provides a method for preparing a ketoxime compound, the method comprising: under the conditions of a ketoammoxime reaction, in the presence of a titanium-silicon molecular sieve catalyst, the ketone compound, peroxidized Hydrogen, water and ammonia are fed into the reactor for contact reaction, and the molar ratio of hydrogen peroxide to the ketone compound is 0.1 to less than 1.

[0028] According to the preparation method of the ketoxime compound provided by the present invention, the method preferably further includes: separating the titanium-silicon molecular sieve catalyst through the contact reaction and the catalyst containing ketoxime compound, ketone compound and A mixed liquid A of water, and separate the ketoxime compound and the mixed liquid B containing ketone compound and water from the mixed liquid A, and then return the mixed liquid B as part of the feed to the reactor to the ...

Embodiment approach

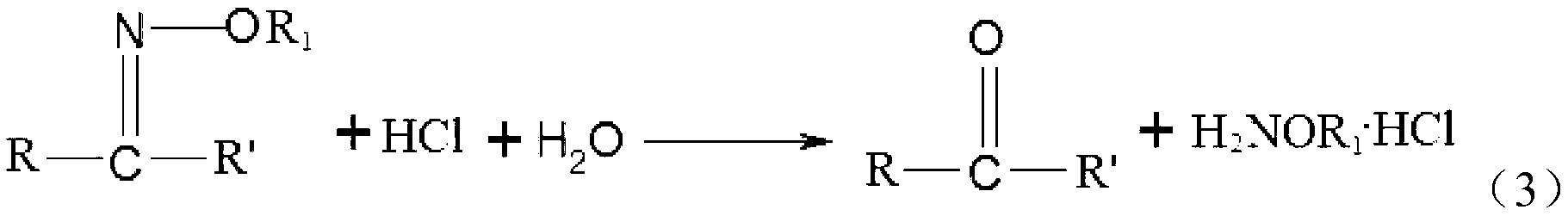

[0077] It can be seen from the above reaction formula (3) that another product of step (3) is the same substance as the ketone compound described in step (1), and in the catalytic rectification process, the ketone compound is obtained from the second rectification process. The top of the tower is discharged. In addition, since there is no additional organic solvent in the step (3), the ketone compound in the overhead distillate can be directly recycled in the step (1) after being concentrated or not, and the overhead distillate The presence of a small amount of HCl in the effluent is also conducive to stabilizing hydrogen peroxide in step (1). Therefore, according to another preferred embodiment of the present invention, the method further includes: recycling the overhead distillate of the second rectification tower with or without concentration as at least part of the distillate in step (1). ketone compounds. In this preferred embodiment, the ketone compound produced by the ...

Embodiment 1

[0086] This example is used to illustrate the preparation method of the ketoxime compound provided by the present invention.

[0087] Acetone, 27.5% by weight of hydrogen peroxide, ammonia, water and TS-1 molecular sieve catalyst (prepared according to the method of Example 1 in CN1301599A) are continuously injected into a 5L slurry bed reactor provided with a ceramic membrane separator, acetone, water The weight ratio of TS-1 molecular sieve catalyst (prepared according to the method of Example 1 in patent application CN1301599A) is 1:2:0.05, and the molar ratio of ammonia to acetone is 1.6:1. The molar ratio of hydrogen peroxide to acetone was 0.9:1, and then by controlling the feed flow and discharge flow of the slurry bed reactor, the reaction raw materials were kept at 50°C for 1 hour. At the same time, the reacted material discharged from the slurry bed reactor is separated into reacted TS-1 molecular sieve catalyst and reaction liquid through the ceramic membrane separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Benzene adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com