Resourceful treatment apparatus and method for waste liquid of chlorohydric acid pickling of steel

A technology for pickling waste liquid and treatment method, which is applied in the fields of metallurgical waste water treatment, chemical instruments and methods, separation methods, etc. It can improve the coagulation effect, improve the distillation effect, and have both environmental value and economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

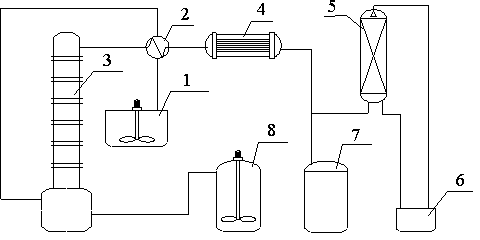

Image

Examples

Embodiment 1

[0021] Step 1. Add solid calcium chloride to the waste hydrochloric acid pickling liquid, and carry out intermittent distillation operation to the waste hydrochloric acid pickling liquid under normal pressure;

[0022] Take the hydrochloric acid pickling waste liquid and place it in the distillation still, add solid calcium chloride, the addition of solid is 1mol / L. Heating and distilling, stop the distillation when the volume ratio of the collected distillate condensate to the addition of hydrochloric acid waste liquid is 3:10;

[0023] Step 2. Add oxidant sodium chlorate and stabilizer sodium phosphate to the distillation mother liquor under stirring conditions, and carry out oxidation and polymerization under normal temperature and pressure;

[0024] In the hydrochloric acid pickling waste distillation mother liquor processed in step one, add water to dilute to prevent crystallization from separating out, add stabilizer sodium phosphate to the hydrochloric acid pickling was...

Embodiment 2

[0029] Step 1. Add solid calcium chloride to the waste hydrochloric acid pickling liquid, and carry out intermittent distillation operation to the waste hydrochloric acid pickling liquid under normal pressure;

[0030] Take the hydrochloric acid pickling waste liquid and place it in the distillation still, add solid calcium chloride, the addition of solid is 0.75mol / L. Heating and distilling, stop the distillation when the volume ratio of the collected distillate condensate to the addition of hydrochloric acid waste liquid is 3.5:10;

[0031] Step 2. Add oxidant sodium chlorate and stabilizer sodium phosphate to the distillation mother liquor under stirring conditions, and carry out oxidation and polymerization under normal temperature and pressure;

[0032] In the hydrochloric acid pickling waste distillation mother liquor processed in step one, add water to dilute to prevent crystallization from separating out, add stabilizer sodium phosphate to the hydrochloric acid picklin...

Embodiment 3

[0037] Step 1. Add solid calcium chloride to the waste hydrochloric acid pickling liquid, and carry out intermittent distillation operation to the waste hydrochloric acid pickling liquid under normal pressure;

[0038] Take the hydrochloric acid pickling waste liquid and place it in the distillation still, add solid calcium chloride, the addition of solid is 1.25mol / L. Heating and distilling, stop the distillation when the volume ratio of the collected amount of distilled condensate to the addition of hydrochloric acid waste liquid is 4:10;

[0039] Step 2. Add oxidant sodium chlorate and stabilizer sodium phosphate to the distillation mother liquor under stirring conditions, and carry out oxidation and polymerization under normal temperature and pressure;

[0040] In the hydrochloric acid pickling waste distillation mother liquor processed in step one, add water to dilute to prevent crystallization from separating out, add stabilizer sodium phosphate to the hydrochloric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com