Preparation method of macromonomer methallyl alcohol polyoxyethylene ether of polycarboxylate water reducer

A technology of methallyl alcohol polyoxyethylene ether and methallyl alcohol, which is applied in the field of polyether synthesis in organic chemistry, can solve the problems of complex production process, overpressure of the reactor, easy gasification, etc. Simple process, reduced isomerization, and low PEG content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

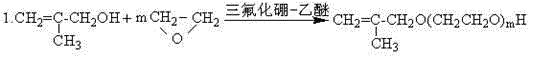

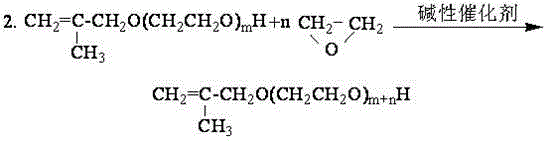

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 methallyl alcohol polyoxyethylene (60) ether

[0027] Add 0.75 mol (54 g) of methallyl alcohol and 1.92 g of boron trifluoride-diethyl ether into a 5 L pressure reactor, and connect the ethylene oxide metering tank to the pressure tank. Replace the air in the kettle with nitrogen for 3 times, and when the temperature of the kettle rises to 50-55° C., 7.5 mol (330 g) of ethylene oxide is passed through for 3.5 hours, and the reaction is continued for 0.5 hours. Then add an aqueous potassium hydroxide solution containing 30.51g of potassium hydroxide, dehydrate at 100°C for 1 hour, keep the temperature of the kettle at 100-105°C, feed 37.5mol (1650g) of ethylene oxide, and complete the process in 6.5 hours , continue to react for 0.5 hours. After the reaction is completed, cool down, release the pressure, add acetic acid for neutralization, and slice to obtain colorless flakes.

Embodiment 2

[0028] The preparation of embodiment 2 methallyl alcohol polyoxyethylene (50) ether

[0029] Add 0.5 mol (36 g) of methallyl alcohol and 0.07 g of boron trifluoride-diethyl ether into a 5 L pressure reactor, and connect the ethylene oxide metering tank to the pressure tank. The air in the kettle was replaced with nitrogen for 3 times, and when the temperature of the kettle rose to 30-35°C, 2.5 mol (110 g) of ethylene oxide was passed through for 2.5 hours, and the reaction was continued for 0.5 hours. Then add an aqueous sodium hydroxide solution containing 1.14g of sodium hydroxide, dehydrate at 100°C for 1 hour, wait for the temperature of the kettle to rise to 155-160°C, and feed 22.5mol (990g) of ethylene oxide for 2.5 hours After passing through, continue to react for 0.5 hour. After the reaction is completed, cool down, release the pressure, add acetic acid for neutralization, and slice to obtain colorless flakes.

Embodiment 3

[0030] Embodiment 3 Preparation of methallyl alcohol polyoxyethylene (55) ether

[0031] Add 1.0mol (72g) of methallyl alcohol and 1.21g of boron trifluoride-ether into a 5L pressure reactor, and connect the ethylene oxide metering tank to the pressure reactor. Replace the air in the kettle with nitrogen for 3 times. After the temperature of the kettle rises to 65-70° C., 7.5 mol (330 g) of ethylene oxide is passed through for 0.5 hours, and the reaction is continued for 0.5 hours. Then add sodium methoxide methanol solution containing 19.94g of sodium methoxide, demethanol at 100°C for 1 hour, wait for the temperature of the kettle to rise to 130-135°C, and feed 47.5mol (2090g) of ethylene oxide for 4.5 hours After passing through, continue to react for 0.5 hour. After the reaction is completed, cool down, release the pressure, add acetic acid for neutralization, and slice to obtain colorless flakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com