Substrate and preparation method thereof

A substrate, porous glass ceramic technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve problems such as limited effect, and achieve the effect of low dielectric constant, reduced loss, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

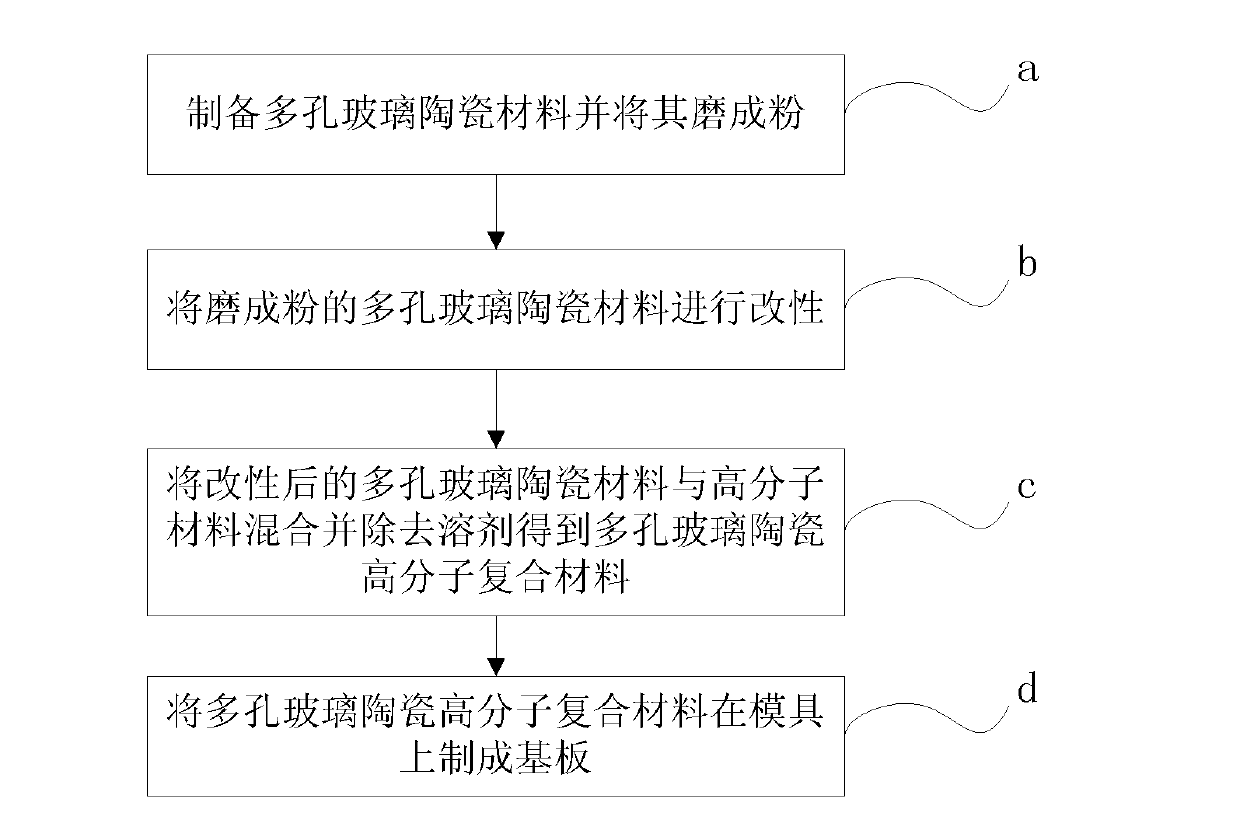

[0028] A method for preparing a substrate, such as figure 1 As shown, the steps of the method include:

[0029] a, preparing porous glass-ceramic material and grinding it into powder;

[0030] b. modifying the powdered porous glass-ceramic material;

[0031] c. Mixing the modified porous glass-ceramic material with a polymer material and removing the solvent to obtain a porous glass-ceramic polymer composite material;

[0032] d. Making the porous glass-ceramic-polymer composite material into a substrate on a mould.

[0033] Said step a comprises: by weight ratio 25.1%~33.2% CaO, 6.3%~12.1% B 2 o 3 and 55.4% to 65.3% SiO 2 Put it in a ball mill and grind it evenly, then press it into tablets, then heat it up to 900°C in a roasting furnace at a rate of 5-10°C, keep it warm at 900°C, cool to room temperature, and then grind it into powder.

[0034] The step b includes: placing the porous glass-ceramic material powder in a beaker, adding silane coupling agent and ethanol, w...

Embodiment 1

[0038] 30.1% CaO, 8.3% B by weight 2 o 3 and 61.6% SiO 2 Put it in a ball mill and grind it evenly, then press it into tablets, then heat it up to 900°C at a rate of 5°C in a roasting furnace, keep it at 900°C for 3 hours, cool to room temperature, and then grind it into powder.

[0039] The porous glass-ceramic material powder is placed in a beaker, and silane coupling agent and ethanol are added, wherein the weight ratio of the silane coupling agent porous glass-ceramic material powder is 1:100, and the volume ratio of ethanol to the porous glass-ceramic material powder is The ratio is 80:1, and then the modified porous glass-ceramic material is obtained after ultrasonic dispersion, heating and stirring, centrifugation and washing.

[0040] Place the beaker on the stirrer, add toluene and polymer material and heat to 100°C, add the modified porous glass ceramic material while stirring to form a mixed solution, wherein the volume ratio of toluene to polymer material is 100:...

Embodiment 2

[0044] 29.3% CaO, 9.3% B by weight 2 o 3 and 61.4% SiO 2 Put it in a ball mill and grind it evenly, then press it into tablets, then heat it up to 900°C at a rate of 8°C in a roasting furnace, keep it at 900°C for 3 hours, cool to room temperature, and then grind it into powder.

[0045] The porous glass-ceramic material powder is placed in a beaker, and silane coupling agent and ethanol are added, wherein the weight ratio of the silane coupling agent porous glass-ceramic material powder is 1.1:95, and the volume ratio of ethanol to the porous glass-ceramic material powder is The ratio is 90:1, and then the modified porous glass-ceramic material is obtained after ultrasonic dispersion, heating and stirring, centrifugation and washing.

[0046] Place the beaker on the stirrer, add toluene and polymer material and heat to 100°C, add the modified porous glass ceramic material while stirring to form a mixed solution, wherein the volume ratio of toluene to polymer material is 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com