Method for curing and leaching reinforced stone coal navajoite concentrated acid

A technology for strengthening stone and coal vanadium ore, applied in the fields of hydrometallurgy and leaching, can solve the problems of limited application range, high roasting temperature, difficult curing operation, etc. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

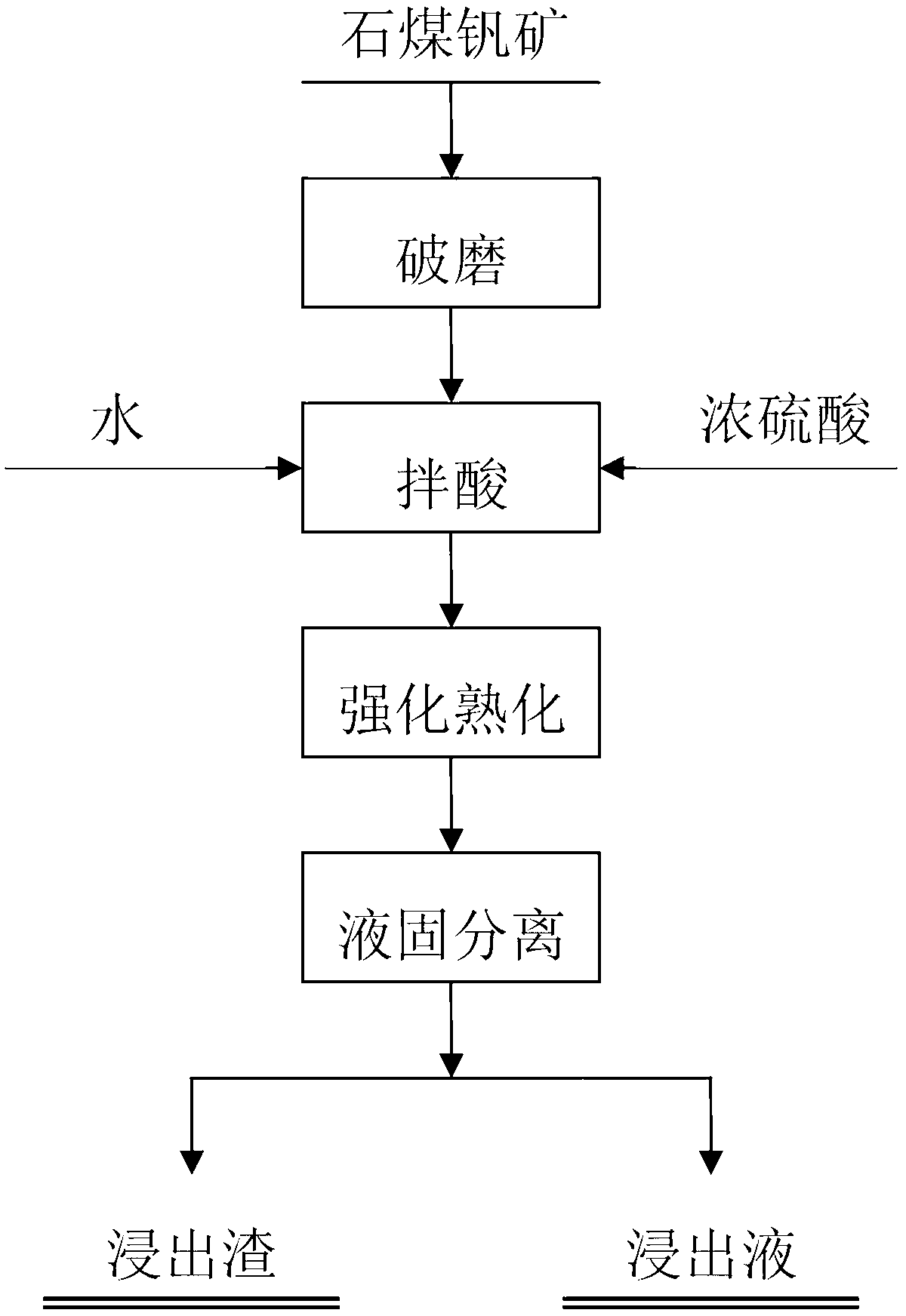

[0029] Stone coal vanadium mine in a certain place, the main chemical composition of the raw ore is C 13.20%, SiO 2 66.76%, Al 2 o 3 6.70%, V 2 o 5 0.92%, using as figure 1 Shown method of the present invention handles stone coal vanadium ore, specifically comprises the following steps:

[0030] First crush and finely grind the stone coal vanadium ore until the particle size is below 0.25mm, and the mineral content below 0.15mm accounts for 81%, add 10% of the stone coal vanadium ore quality water and mix well, then add a certain amount of concentrated sulfuric acid and mix well, The initial concentration of sulfuric acid solution in mineral powder is 66% (the change of the amount of concentrated sulfuric acid is shown in Table 1 below), and then the mixture is aged at 120°C for a period of time (the change of curing time is shown in Table 2 below), During the curing process, the pressure in the container is 1.2×10 5 ~1.3×10 5Pa, relative humidity of 60% to 65%, and ...

Embodiment 2

[0037] Stone coal vanadium mine in a certain place, the chemical composition of the raw ore mainly includes C 15.00%, SiO 2 58.46%, Al 2 o 3 8.72%, V 2 o 5 1.00%, using as figure 1 The shown method of the present invention processes this stone coal vanadium ore, specifically comprising the following steps:

[0038] First crush and finely grind the stone coal vanadium ore to less than 0.15mm, add water with 10% mass of stone coal vanadium ore and mix well, then add a certain amount of concentrated sulfuric acid and mix well (the amount of concentrated sulfuric acid changes as shown in Table 3 below), Then the mixture is aged at 140°C for 7 hours, and the pressure in the container is 1.2×10 during the aging process. 5 ~1.3×10 5 Pa, relative humidity of 60% to 63%, and no ventilation, the evaporation of water is 55% to 56% of the added amount. The obtained clinker was leached in water with a liquid-solid ratio of 2:1 for 2 h. After liquid-solid separation, the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com