Coating process of crystalline silicon solar cell

A technology of solar cells and crystalline silicon, which is applied in the coating process of metal materials, circuits, electrical components, etc., and can solve problems affecting the photoelectric conversion efficiency of solar cells, affecting the uniformity of silicon nitride films, uneven temperature and atmosphere, etc. , to achieve the effect of shortening process time, saving ammonia gas and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

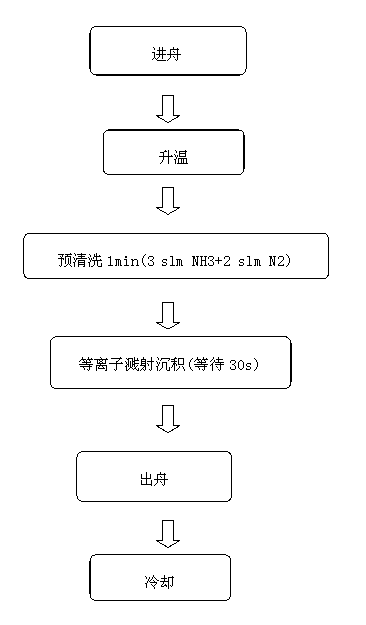

[0038] like figure 1 As shown, a company prepares silicon nitride film by PECVD of polysilicon. Each boat holds 240 silicon wafers. The process is as follows: (1) enter the boat for 2 minutes; (3) Pre-cleaning, the ammonia gas with a flow rate of 3 slm (standard liters / minute) is introduced, and the nitrogen gas with a flow rate of 2 slm (standard liters / minute) is introduced at the same time, and the radio frequency pre-cleaning is turned on for 1 minute; (4) Plasma sputtering For sputtering deposition, the flow rate is 6.8 slm (standard liter / min) ammonia gas and 700 ml / min silane, wait for 30s and start RF plasma sputtering deposition for 13.3 minutes; (5) out of the boat, 2 minutes; (6) cooling, 6 minute.

Embodiment 2

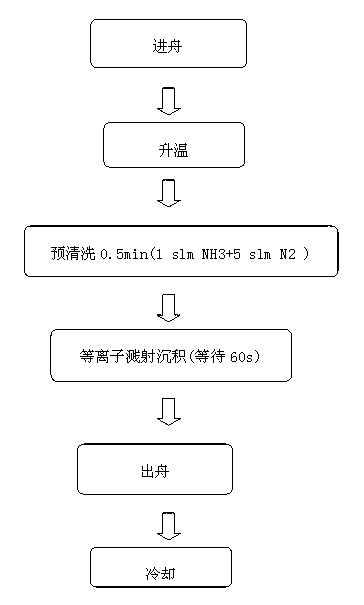

[0040] like figure 2 As shown, embodiment 2 is the coating process of crystalline silicon solar cells of the present invention. A company prepares silicon nitride thin films by single crystal PECVD. Each boat holds 240 silicon wafers. The process is as follows: (1) enter the boat for 2 minutes; ) pre-cleaning, the ammonia gas with a flow rate of 1 slm (standard liter / min) is introduced, and the nitrogen gas with a flow rate of 5 slm (standard liter / min) is introduced at the same time, and the radio frequency pre-cleaning is turned on for 0.5 minutes; (4) Plasma sputtering deposition , the flow rate is 6.8 slm (standard liter / min) ammonia gas and 660 ml / min silane, wait for 60s to open RF plasma sputtering deposition for 13.8 minutes; (5) out of the boat, 2 minutes; (6) cooling, 6 minutes.

[0041] The present invention feeds ammonia and nitrogen at the same time during pre-cleaning, which can not only ensure that hydrogen atoms can passivate defects such as impurities and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com