Feed for weaned pigs and preparation method for feed

A technology of suckling pig feed and suckling pig feed, which is applied in animal feed, animal feed, animal husbandry, etc., can solve the problem of single means, and achieve the effect of good taste of raw materials, less loss of nutrients, easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

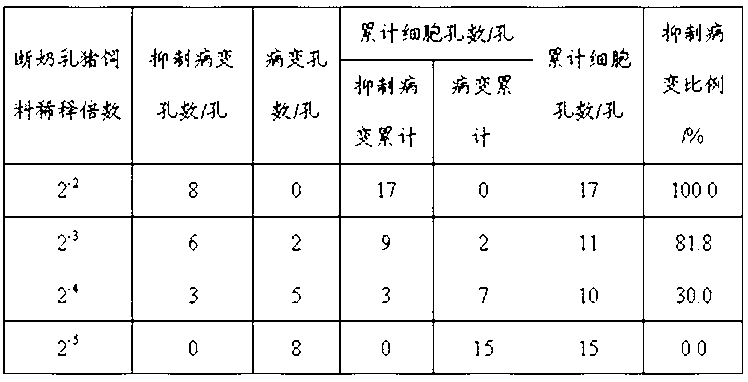

Image

Examples

Embodiment 1

[0034] A preparation method for weaned pig feed comprises the steps:

[0035] First, use microwave equipment to microwave corn and soybeans. The microwave frequency is 2450 MHz. The processing time for corn is 30 seconds, and the processing time for imported soybeans is 80 seconds. Corn flour and crushed microwave soybean flour are set aside;

[0036] Then prepare the core material of weaned suckling pig feed, accurately weigh 5 parts of α-interferon (potency 30 million IU / kg), 5 parts of cecropin antimicrobial peptide, 10 parts of astragalus polysaccharide, 25 parts of potato protein, and 10 parts of red cabbage extract. 5 parts of tea polyphenols, 20 parts of wheat hydrolyzed protein powder containing glutamine (among them, the mass percentage of glutamine is 30%), 15 parts of isomaltooligosaccharides, 5 parts of arginine and all added to a volume of 200L Mix in the mixer for 180 seconds, and the mixing coefficient of variation is required to be less than 5%; finally prepar...

Embodiment 2

[0043] A preparation method for weaned pig feed:

[0044] First, use microwave equipment to microwave corn and soybeans. The microwave frequency is 950 MHz. The processing time for corn is 40 seconds, and the processing time for imported soybeans is 90 seconds. Corn flour and crushed microwave soybean flour are set aside;

[0045] Then prepare the core material of weaned suckling pig feed, accurately weigh 3 parts of α-interferon (potency 50 million IU / kg), 3 parts of cecropin antimicrobial peptide, 7 parts of astragalus polysaccharide, 15 parts of potato protein, and 7 parts of red cabbage extract 8 parts of tea polyphenols, 15 parts of wheat hydrolyzed protein powder containing 30% glutamine, 5 parts of isomaltooligosaccharide, 3 parts of arginine and all added to a 200L mixer and mixed for 190 seconds, the mixing coefficient of variation is required <5%; finally prepare microwave-processed weaned suckling pig compound feed, with 100 parts by weight, first add 45 parts of c...

Embodiment 4

[0063] A preparation method of feed for weaned pigs:

[0064] First, use microwave equipment to microwave corn and soybeans. The microwave frequency is 1400 MHz. The processing time for corn is 35 seconds, and the processing time for imported soybeans is 86 seconds. Corn flour and crushed microwave soybean flour are set aside;

[0065] Then prepare the core material of weaned suckling pig feed, accurately weigh 6 parts of α-interferon (potency 37 million IU / kg), 6 parts of cecropin antimicrobial peptide, 12 parts of astragalus polysaccharide, 17 parts of potato protein, and 9 parts of red axle extract 7 parts of tea polyphenols, 18 parts of wheat hydrolyzed protein powder containing high glutamine, 12 parts of isomaltooligosaccharide, 8 parts of arginine and all added to a 200L mixer and mixed for 200 seconds, the mixing coefficient of variation is required <5%; finally prepare microwave-processed weaned suckling pig compound feed, with 100 parts by weight, first add 50 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com