Volcanic filler-based sewage treatment system of biological aerated filter

A technology of biological aerated filter and sewage treatment system, which is applied in biological water/sewage treatment, sustainable biological treatment, multi-stage water/sewage treatment, etc., and can solve the problems of fast filler renewal, low removal rate, large head loss, etc. Problems, low equipment investment and operating costs, reduced filter volume, and strong load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

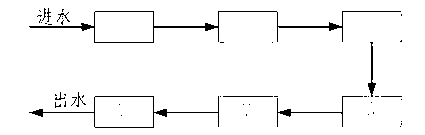

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The sewage treatment system based on volcanic rock filler biological aerated filter mainly includes medium grid tank, pump room, grit chamber, anoxic reaction tank, ultra-fine grid lifting tank, and biological aerated filter. The domestic sewage enters the medium grid through the sewage pipeline for treatment, and then enters the grit chamber. After being settled in the grit chamber, the wastewater enters the superfine grid lifting tank through the lifting pump. The lifting pump is located in the ultra-fine grid lifting pool, and the water in the ultra-fine grid lifting pool enters the bottom of the biological aerated filter through the lifting pump and the water inlet pipe. The operating characteristics in the anoxic reaction tank are hydraulic retention time of 6-8 hours and COD removal rate of 10%-15%.

[0027] The raw water of the biological aerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com