Rare earth phosphate scintillating glass and preparation method of same

A rare earth phosphate and scintillation glass technology, applied in the field of inorganic rare earth luminescent materials, can solve the problems of unsatisfactory light yield of glass, short fluorescent life, low light output, etc., and achieves improved radiation resistance performance and simple preparation process. , the effect of short fluorescence lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

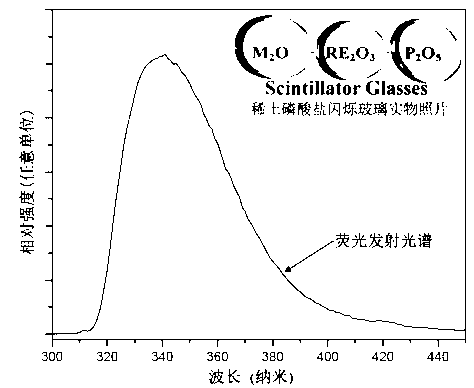

Embodiment 1

[0022] Weigh out ammonium dihydrogen phosphate (NH 4 H 2 PO 4 ) 6.9000 g, lithium carbonate (Li 2 CO 3 ) 0.5542 g, yttrium oxide (Y 2 O 3 ) 1.6919 g, cerium oxide (CeO 2 ) 0.0026 g, mixed uniformly, pre-fired at 300°C, heated to 1100°C, held at a constant temperature for 30 minutes, poured into a mold, and annealed at 500°C to obtain transparent rare earth phosphate scintillation glass.

Embodiment 2

[0024] Weigh out ammonium dihydrogen phosphate (NH 4 H 2 PO 4 ) 6.9000 g, lithium carbonate (Li 2 CO 3 ) 0.5542 g, yttrium oxide (Y 2 O3 ) 1.6766 g, cerium oxide (CeO 2 ) 0.0258 g, mixed evenly, pre-fired at 400°C, raised to 1200°C, kept at a constant temperature for 30 minutes, poured into a mold, and annealed at 500°C to obtain transparent rare earth phosphate scintillation glass.

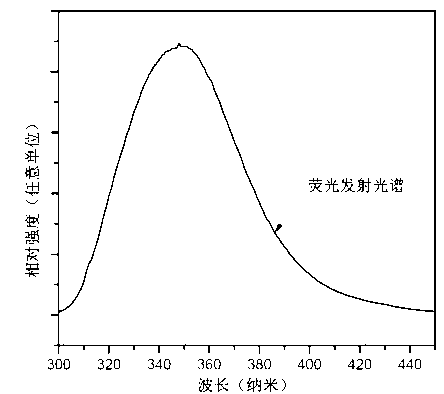

Embodiment 3

[0026] Weigh ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 6.9000 grams, lithium carbonate (Li 2 CO 3 ) 0.5542 g, lutetium oxide (Lu 2 o 3 ) 2.8353 g, cerium oxide (CeO 2 ) 0.1291 g, mixed evenly, pre-fired at 400°C, heated to 1300°C, kept at a constant temperature for 30 minutes, poured into a mold, and annealed at 500°C to obtain transparent rare earth phosphate scintillation glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com