Precious-metal-enhanced Ce-YAG microcrystalline-glass and preparation method thereof

A technology of glass-ceramic and precious metal, applied in the field of glass-ceramic and its preparation, to achieve the effect of enhancing yellow light emission and facilitating ion exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

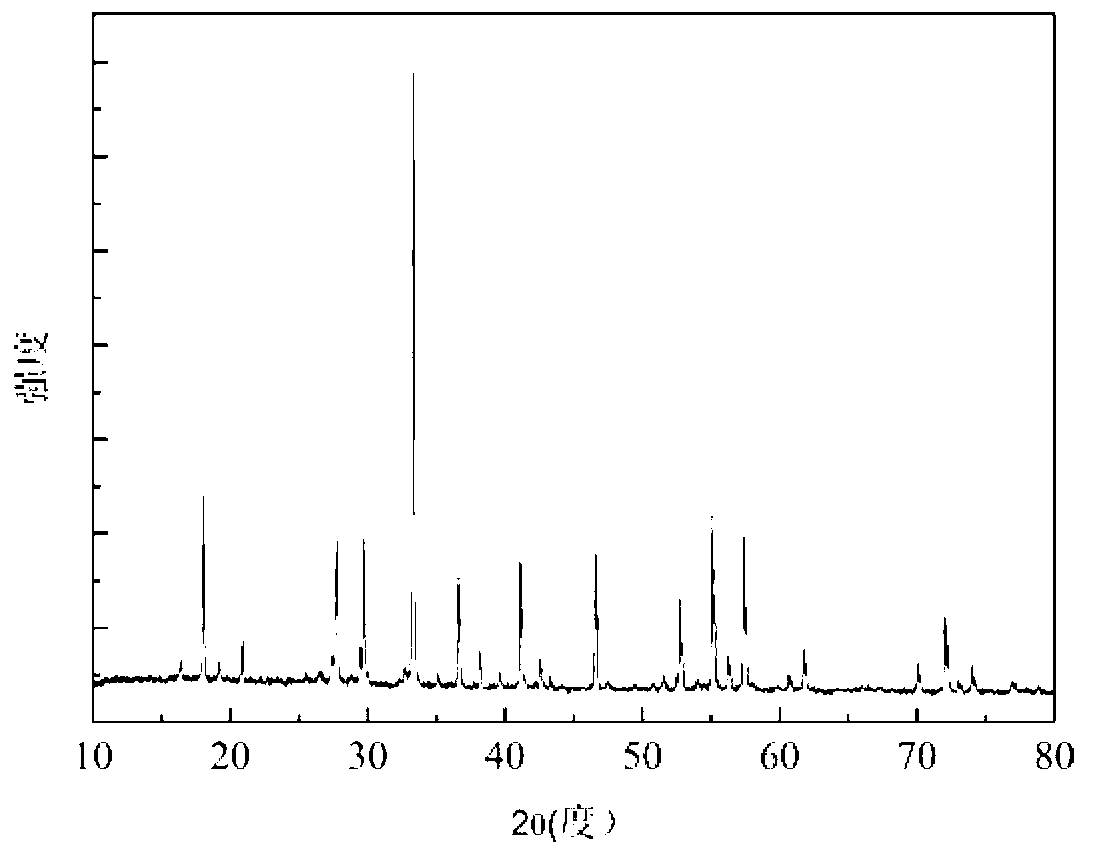

[0016] According to the mole percentage of the components, the glass composition is 45SiO 2 -14.9Y 2 o 3 -26Al 2 o 3 -9Li 2 O-5ZrO 2 -0.1CeO 2 , accurately weighed analytically pure SiO 2 , Y 2 o 3 、Al 2 o 3 , Li 2 CO 3 , ZrO 2 and spectrally pure CeO 2 , mixed well and then poured into a crucible, kept in an electric furnace at 1600°C for 2 hours, poured the molten glass melt into a mold quickly, and quickly transferred to an annealing furnace for annealing after the glass was formed. Differential thermal analysis was performed on the prepared glass, and the first crystallization peak temperature of the glass was measured to be 1050°C. The annealed glass sample was heat-treated at 1050°C for 10 hours, and the annealing furnace was closed to cool down to room temperature naturally to obtain precipitated Ce:YAG Crystalline glass-ceramics. Depend on figure 1 As shown in the X-ray powder diffraction test and compared with the PDF card, the precipitated crystal ph...

Embodiment 2

[0018] In terms of mole percentage of components, the glass composition is 48SiO 2 -10Y 2 o 3 -30Al 2 o 3 -5Li 2 O-2ZrO 2 -3TiO 2 -2CeO 2 , accurately weighed analytically pure SiO 2 , Y 2 o 3 、Al 2 o 3 , Li 2 CO 3 , ZrO 2 、TiO 2 and spectrally pure CeO 2 , mixed well and then poured into a crucible, kept in an electric furnace at 1620°C for 2 hours, poured the molten glass melt into a mold quickly, and quickly transferred to an annealing furnace for annealing after the glass was formed. The obtained glass was subjected to differential thermal analysis, and the first crystallization peak temperature of the glass was measured to be 1080°C. The annealed glass sample was heat-treated at 1080°C for 5 hours, then the annealing furnace was closed and the temperature was naturally cooled to room temperature to obtain precipitated Ce 3+ : Glass-ceramics in YAG crystal phase, cut and polished the glass-ceramics for ion exchange experiments. Formulating AgNO 3 and NaN...

Embodiment 3

[0020] The glass composition is 50SiO in terms of molar percentage of components 2 -15Y 2 o 3 -18Al 2 o 3 -10Li 2 O-5TiO 2 -2CeO 2 , accurately weighed analytically pure SiO 2 , Y 2 o 3 、Al 2 o 3 , Li 2 CO 3 , ZrO 2 、TiO 2 and spectrally pure CeO 2 , mixed well and then poured into a crucible, kept in an electric furnace at 1650°C for 2 hours, poured the molten glass melt into a mold quickly, and quickly transferred to an annealing furnace for annealing after the glass was formed. Differential thermal analysis was performed on the prepared glass, and the first crystallization peak temperature of the glass was measured to be 1100°C. The annealed glass sample was heat-treated at 1100°C for 2 hours, and the annealing furnace was closed to cool down to room temperature naturally to obtain precipitated Ce 3+ Glass-ceramic of Ce:YAG crystal phase, the glass-ceramic was cut and polished for ion exchange experiments. Formulating AgNO 3 and NaNO 3 mixed salts, AgNO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com