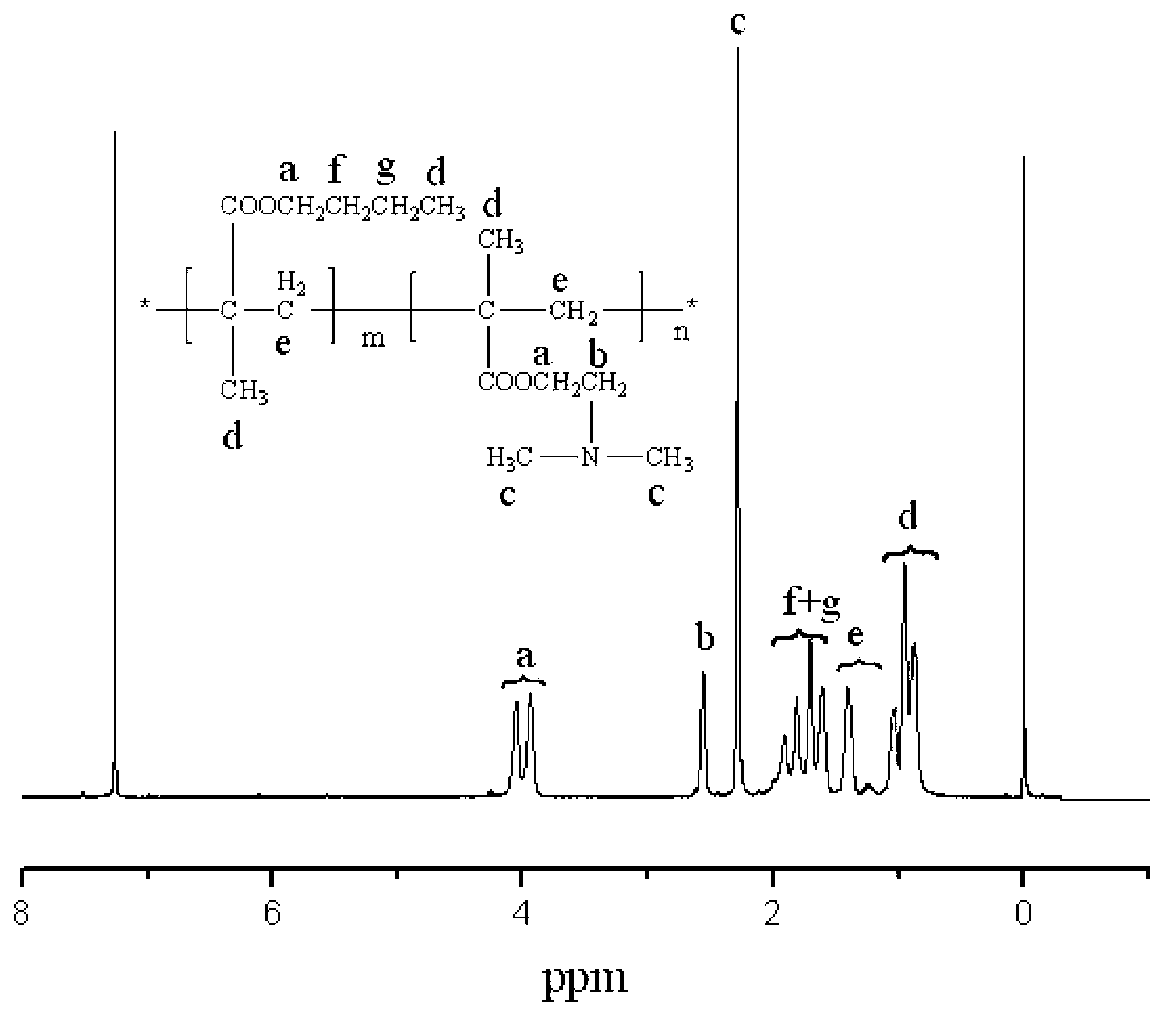

Preparation method of butyl methacrylate-dimethylaminoethyl methacrylate block copolymer

A technology of dimethylaminoethyl methacrylate and butyl methacrylate, which is applied in the field of polymer chemistry, can solve the problems of high cost, catalyst residue in polymers, and large amount of catalyst, so as to achieve low production cost and solve the problem of durability. Reduction of heat and aging resistance, effect of ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

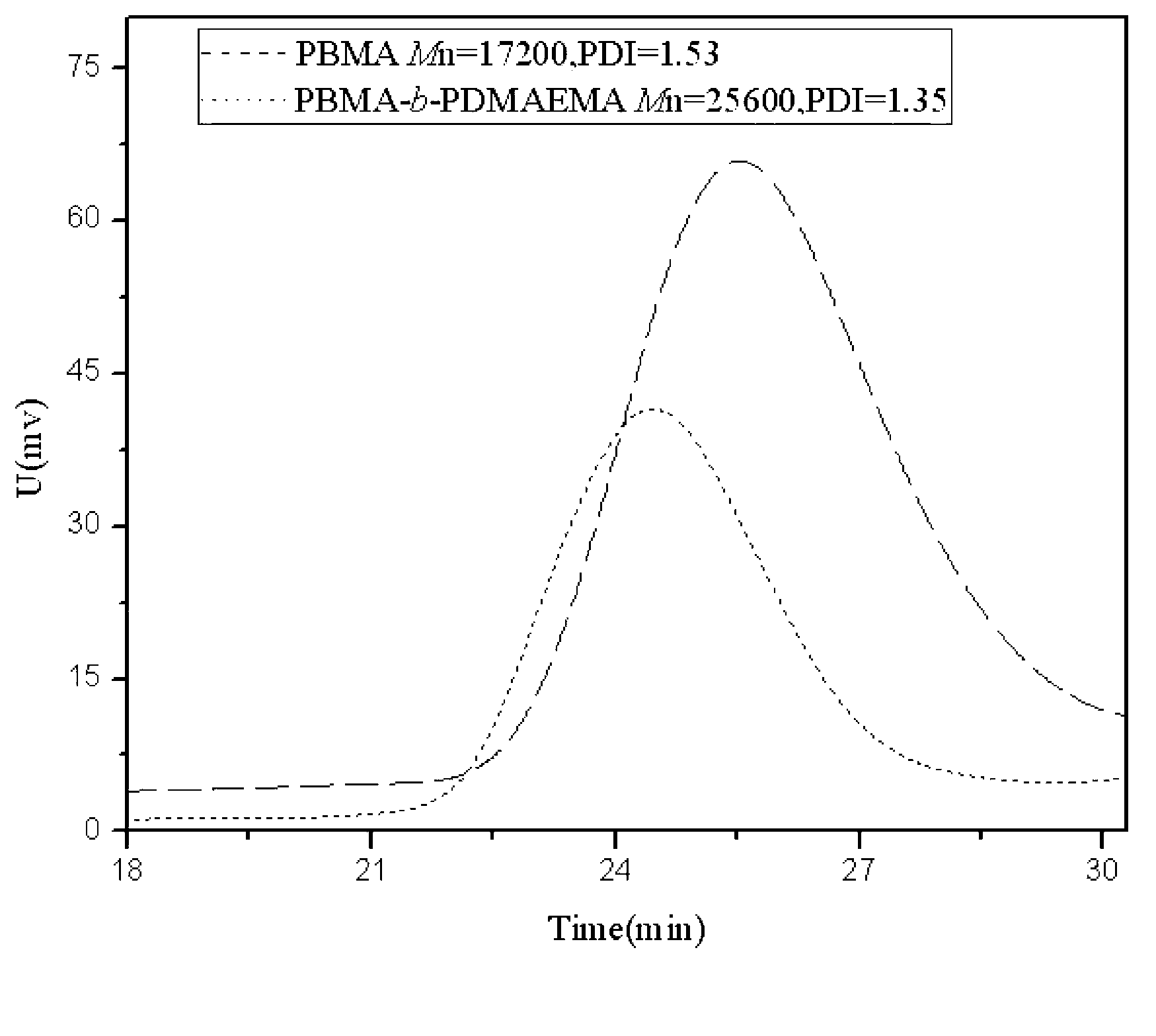

Embodiment 1

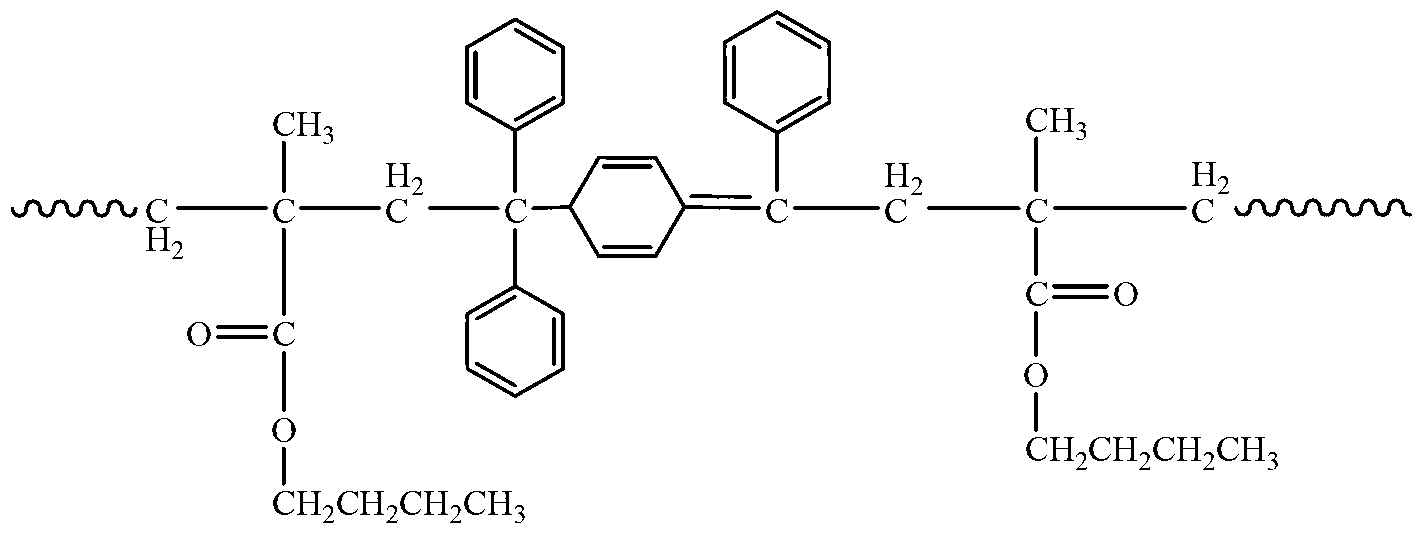

[0023] (1) Polymerization formula: The molar ratio of monomer (BMA), initiator (AIBN), and 1,1-diphenylethylene is 100:0.4:0.8, and toluene equal to 50% of the total mass is added as a solvent.

[0024] Polymerization step: Add 50g (0.35mol) of BMA monomer, 0.2310g (0.0014mol) of initiator AIBN, 0.5070g (0.0028mol) of 1,1-diphenylethylene into a 250mL four-necked flask equipped with a thermometer and a magnetic stirrer ), the solvent toluene 50g, mixed evenly, the system was repeatedly evacuated and argon flowed three times, and reacted at 70°C for 25h.

[0025] Purification of polybutyl methacrylate: After the reaction, the solvent in the system was removed by rotary evaporation until the liquid in the rotary evaporator stopped dripping, and a colorless, transparent and slightly viscous product was obtained. The product after rotary evaporation was dropped into excess methanol to precipitate, filtered, and the obtained precipitate was added to chloroform to dissolve completel...

Embodiment 2

[0030] The PBMA synthesized in step (1) of Example 1 was used as the macroinitiator, and the mass ratio of PBMA and DMAEMA was 1:5, and then 50% of the total amount of butyl acetate was added as a solvent.

[0031] Polymerization step: Add 10g of PBMA, 50g of monomer DMAEMA, and 20g of butyl acetate into a 100mL four-neck flask equipped with a thermometer and a magnetic stirrer. ℃ under the reaction 6h.

[0032] Purification of butyl methacrylate-dimethylaminoethyl methacrylate block copolymer: after the reaction, the solvent in the system was removed by rotary evaporation to obtain a colorless, transparent and viscous product. Rotate the product in a rotary evaporator to remove the solvent until the liquid in the rotary evaporator no longer drips, drop the product after rotary evaporation into excess petroleum ether to precipitate, filter, and add the obtained precipitate to THF Completely dissolve, then drop the THF solution of the precipitate into excess petroleum ether to p...

Embodiment 3

[0034] (1) Polymerization formula: The molar ratio of monomer (BMA), initiator (AIBN), and 1,1-diphenylethylene is 100:1:2, and butyl acetate equal to 50% of the total mass is added as a solvent.

[0035] Polymerization step: Add 50g (0.35mol) of BMA monomer, 0.2310g (0.0035mol) of initiator AIBN, 0.5070g (0.0070mol) of DPE, 50g of solvent toluene into a 250mL four-neck flask equipped with a thermometer and a magnetic stirrer, and mix Evenly, react at 75°C for 20h.

[0036] Purification of polybutyl methacrylate: After the reaction, the solvent in the system was removed by rotary evaporation until the liquid in the rotary evaporator stopped dripping, and a colorless, transparent and slightly viscous product was obtained. The product after rotary evaporation was dropped into excess methanol to precipitate, filtered, and the obtained precipitate was added to chloroform to dissolve completely, then, the precipitate chloroform solution was dropped into excess methanol to precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com