Corrosion preventing and inhibiting agent for bio-based methanol gasoline and preparation method of corrosion preventing and inhibiting agent

A technology of methanol gasoline and corrosion inhibitor, which is applied in the field of anti-corrosion and corrosion-inhibitor, achieves the effect of remarkable anti-corrosion and corrosion-inhibiting effect, less addition, and improved corrosion-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

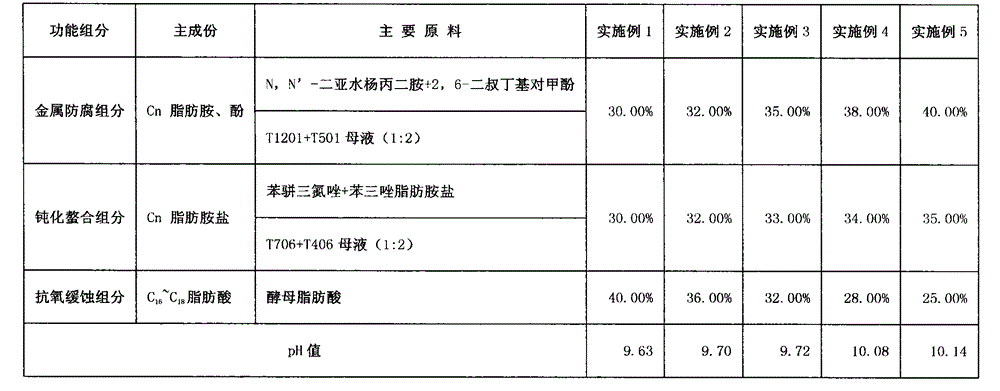

[0025] A bio-based methanol gasoline anticorrosion and corrosion inhibitor is composed of the following volume percentage functional components:

[0026] Metal anti-corrosion component: C n Fatty amines, fatty phenols 30.0%

[0027] Passive Chelating Component: C n Fatty amine salt 30.0%

[0028] Antioxidant corrosion inhibitor component: C 16 ~C 18 Fatty acids 40.0%

[0029] Among them: C of the metal anticorrosion component n The fatty amine is N,N'-di-salicylidenediamine (T1201), and the fatty phenol is 2,6-di-tert-butyl-p-cresol (T501); T1201+ prepared at a volume ratio of 1:2 T501 mother liquor; passivated chelating component C n Fatty amine salt is T706+T406 mother liquor prepared with benzotriazole (T706) and benzotriazole fatty amine salt (T406) at a volume ratio of 1:1; 16 ~C 18 Fatty acid is Petroleum Yeast Fatty Acid C 16 ~C 18 or oleic acid (C 18 h 34 o 2). Add metal anti-corrosion components, passivation chelating components and anti-oxidation and c...

Embodiment 2

[0031] A bio-based methanol gasoline anticorrosion and corrosion inhibitor is composed of the following volume percentage functional components:

[0032] Metal anti-corrosion component: C n Fatty amines, fatty phenols 32.0%

[0033] Passive Chelating Component: C n Fatty amine salt 32.0%

[0034] Antioxidant corrosion inhibitor component: C 16 ~C 18 Fatty acids 36.0%

[0035] Among them: C of the metal anticorrosion component n The aliphatic amine is N, N'-disalicylidene propylenediamine, and the fatty phenol is 2,6-di-tert-butyl-p-cresol; the T1201+T501 mother liquor prepared with a volume ratio of 1:2; passivated chelate Composite C n Fatty amine salt is T706+T406 mother liquor prepared with benzotriazole and benzotriazole fatty amine salt at a volume ratio of 1:1; 16 ~C 18 Fatty acid is Petroleum Yeast Fatty Acid C 16 ~C 18 or oleic acid (C 18 h 34 o 2 ). Add metal anti-corrosion components, passivation chelating components and anti-oxidation and corrosion in...

Embodiment 3

[0037] A bio-based methanol gasoline anticorrosion and corrosion inhibitor is composed of the following volume percentage functional components:

[0038] Metal anti-corrosion component: C n Fatty amines, fatty phenols 35.0%

[0039] Passive Chelating Component: C n Fatty amine salt 33.0%

[0040] Antioxidant corrosion inhibitor component: C 16 ~C 18 Fatty acids 32.0%

[0041] Among them: C of the metal anticorrosion component n The aliphatic amine is N, N'-disalicylidene propylenediamine, and the fatty phenol is 2,6-di-tert-butyl-p-cresol; the T1201+T501 mother liquor prepared with a volume ratio of 1:2; passivated chelate Composite C n Fatty amine salt is T706+T406 mother liquor prepared with benzotriazole and benzotriazole fatty amine salt at a volume ratio of 1:1; 16 ~C 18 Fatty acid is Petroleum Yeast Fatty Acid C 16 ~C 18 or oleic acid (C 18 h 34 o 2 ). Add metal anti-corrosion components, passivation chelating components and anti-oxidation and corrosion in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com