Preparation method and application of three-dimensional graphene-based stannic oxide composite material

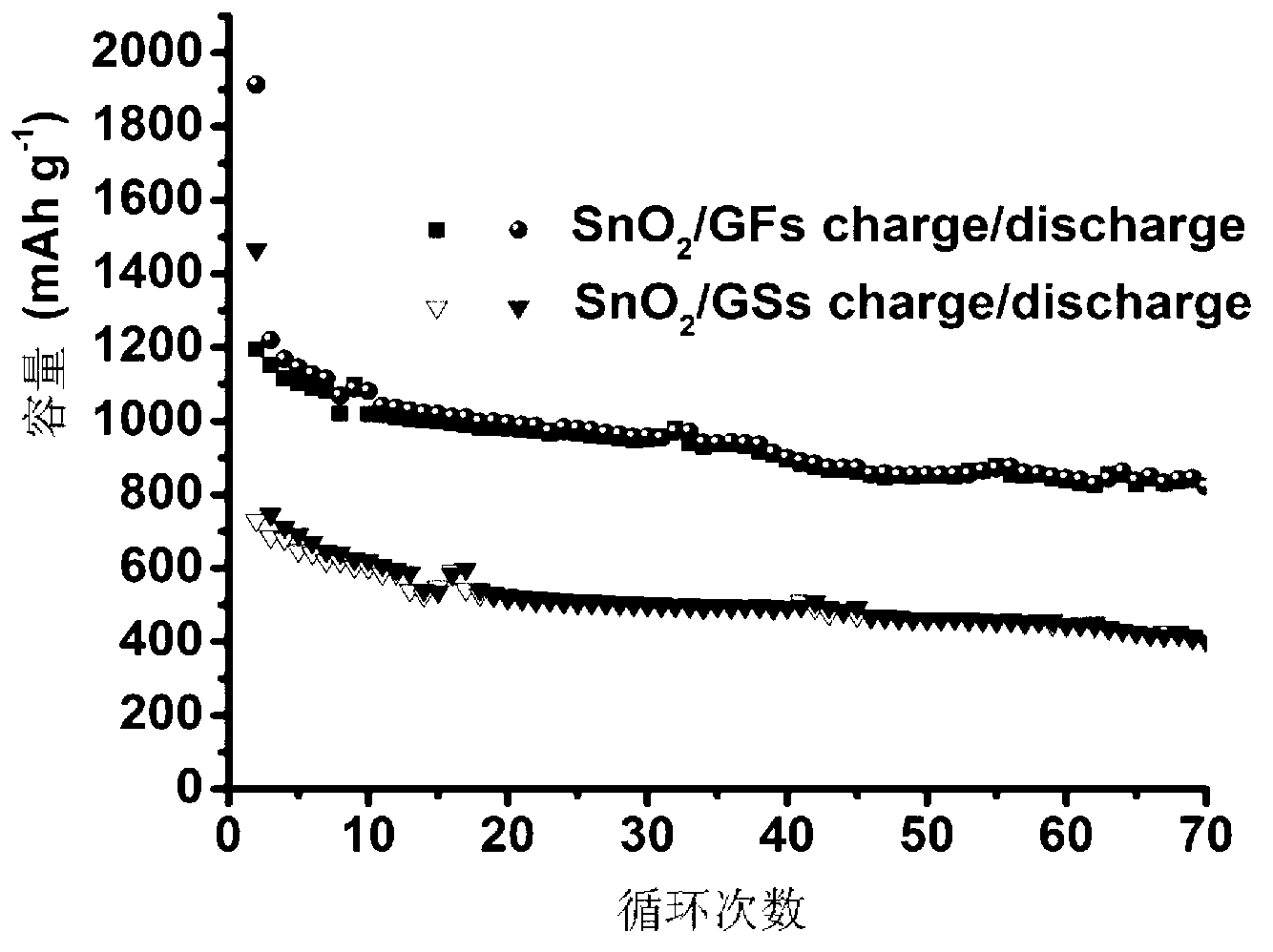

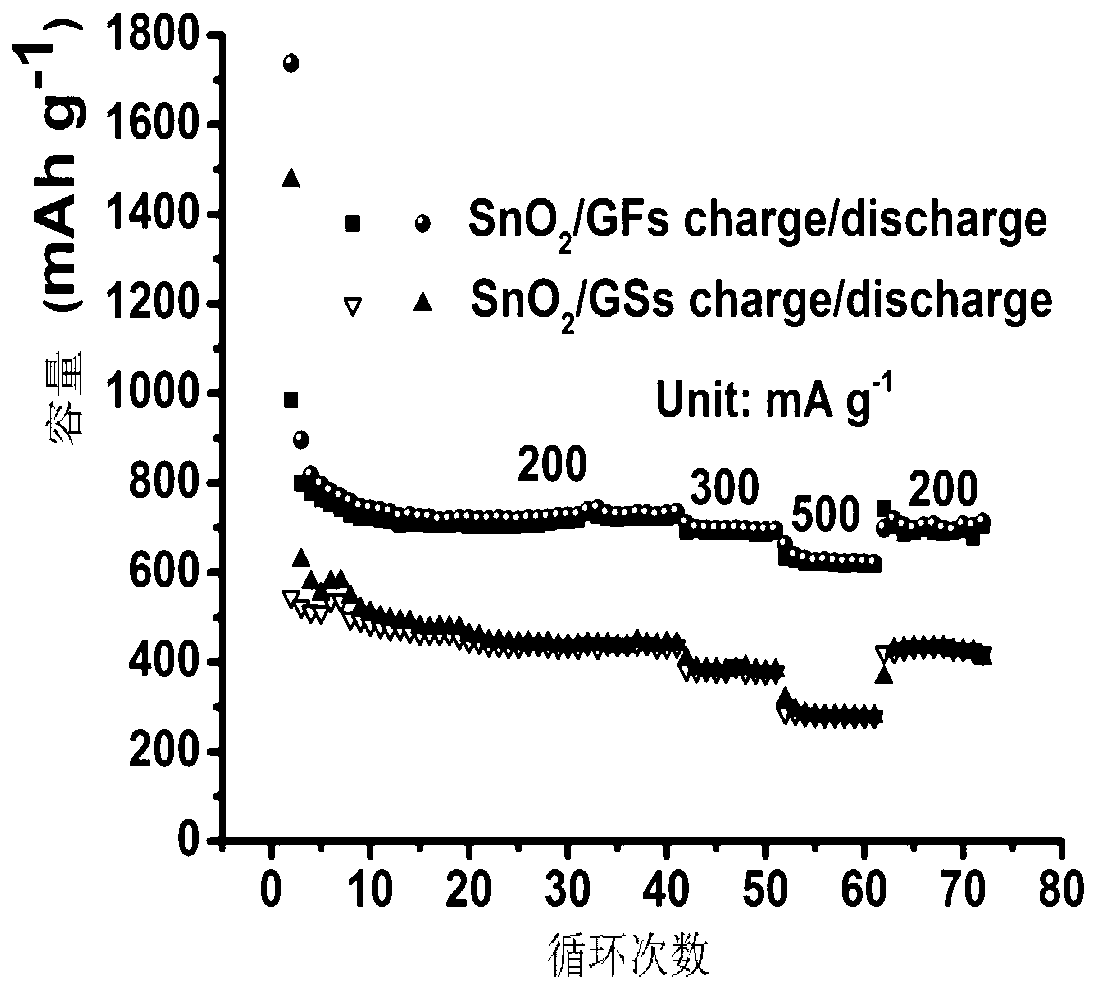

A graphene-based, tin dioxide technology, applied in the fields of materials science and electrochemistry, can solve the problems of rapid capacity decay, limitation, electrode powdering, etc., and achieve excellent rate performance and excellent cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

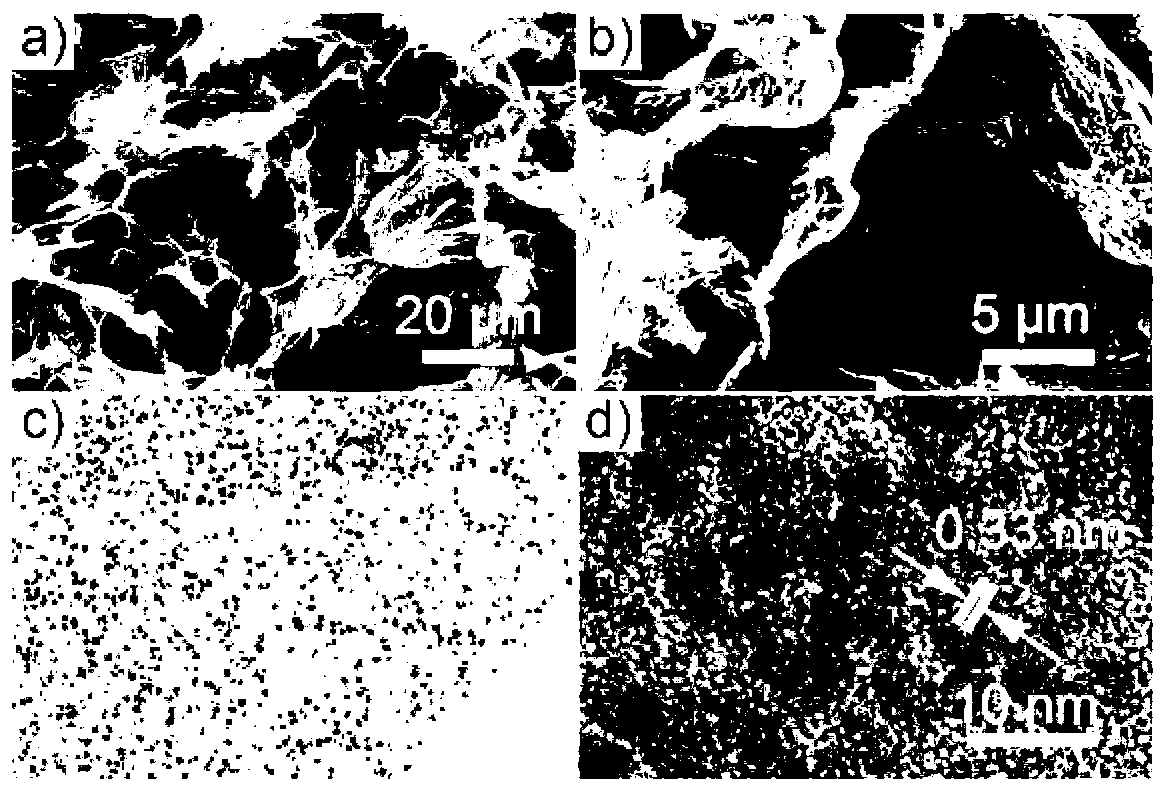

Image

Examples

Embodiment 1

[0038] The first step, preparation of graphene-based tin dioxide nanosheets:

[0039] (1) Sonicate 1mg / mL graphene oxide dimethylformamide solution (50mL) to form a uniformly mixed dispersion;

[0040] (2) Add concentrated hydrochloric acid to the above dispersion to adjust the pH of the solution to 2; add tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), keep warm at 80°C for 12 hours after adding, and cool;

[0041] Among them, the added SnCl 4 2H 2 The mass ratio of O to graphene oxide was 1.16:1.

[0042] (3) Centrifuge the solution after the above reaction, wash it with deionized water, repeat the centrifugation and washing operations four times, and concentrate to obtain a viscous liquid, which is graphene-based tin dioxide nanosheets.

[0043] The second step is to prepare a graphene-based tin dioxide composite material with a three-dimensional structure:

[0044] (1) Take the viscous body liquid concentrated into 10 mL of the above-prepared graphene-based tin diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com