Dual-wavelength pumping middle-infrared four-wave mixing fiber laser of all-fiber structure

A fiber laser and four-wave mixing technology, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as low conversion efficiency of mid-infrared lasers, increase system complexity, and reduce conversion thresholds to improve coupling Efficiency, high peak power, and the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

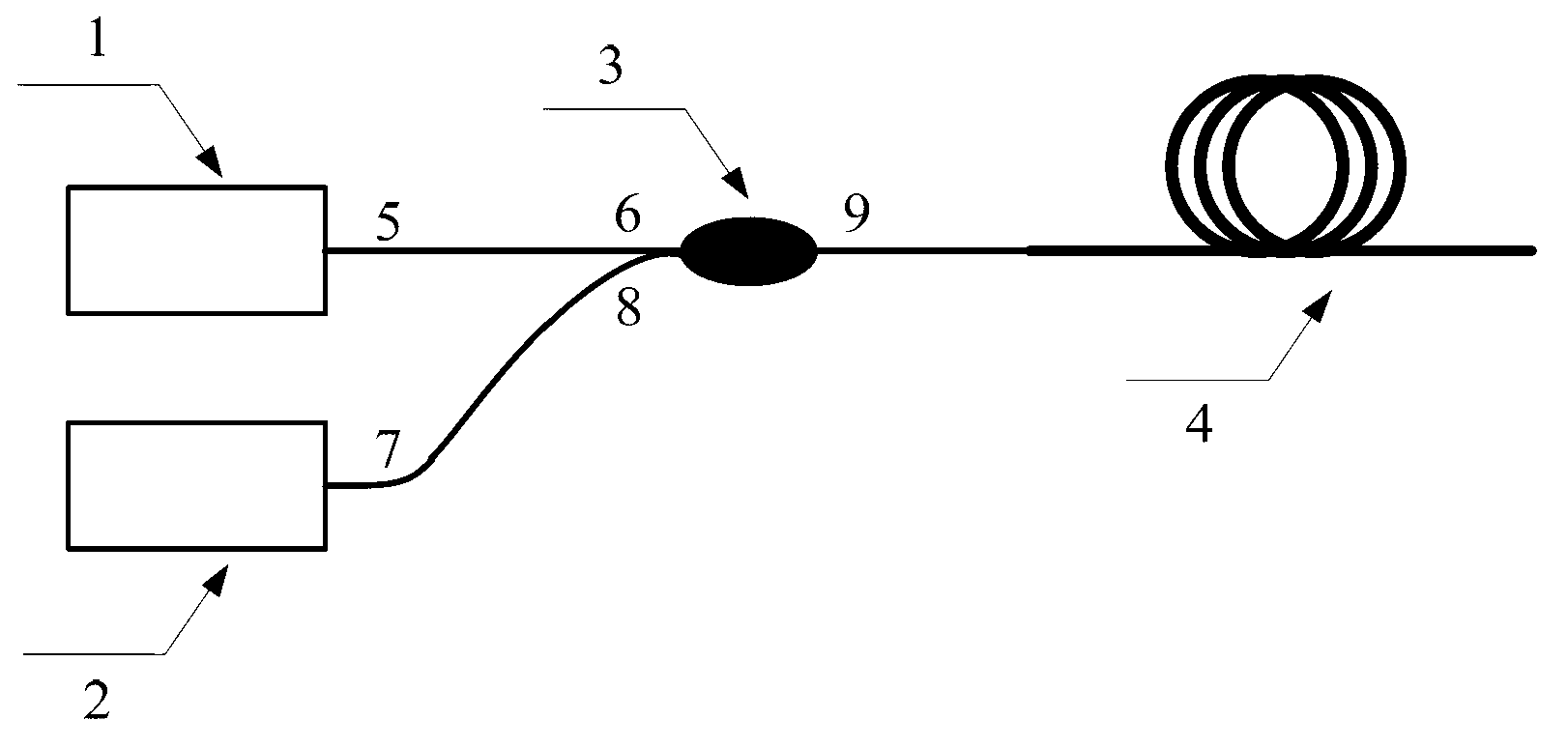

[0022] see first figure 1 , the present invention includes a pulsed fiber laser 1, a continuous fiber laser 2, a wavelength division multiplexer 3, and a mid-infrared soft glass fiber 4; the output fiber 5 of the pulsed fiber laser 1 and the signal input fiber 6 of the wavelength division multiplexer 3 The output fiber 7 of the continuous fiber laser 2 is connected to the signal input fiber 8 of the wavelength division multiplexer 3, and the output fiber 9 of the wavelength division multiplexer 3 is connected to the mid-infrared soft glass fiber 4.

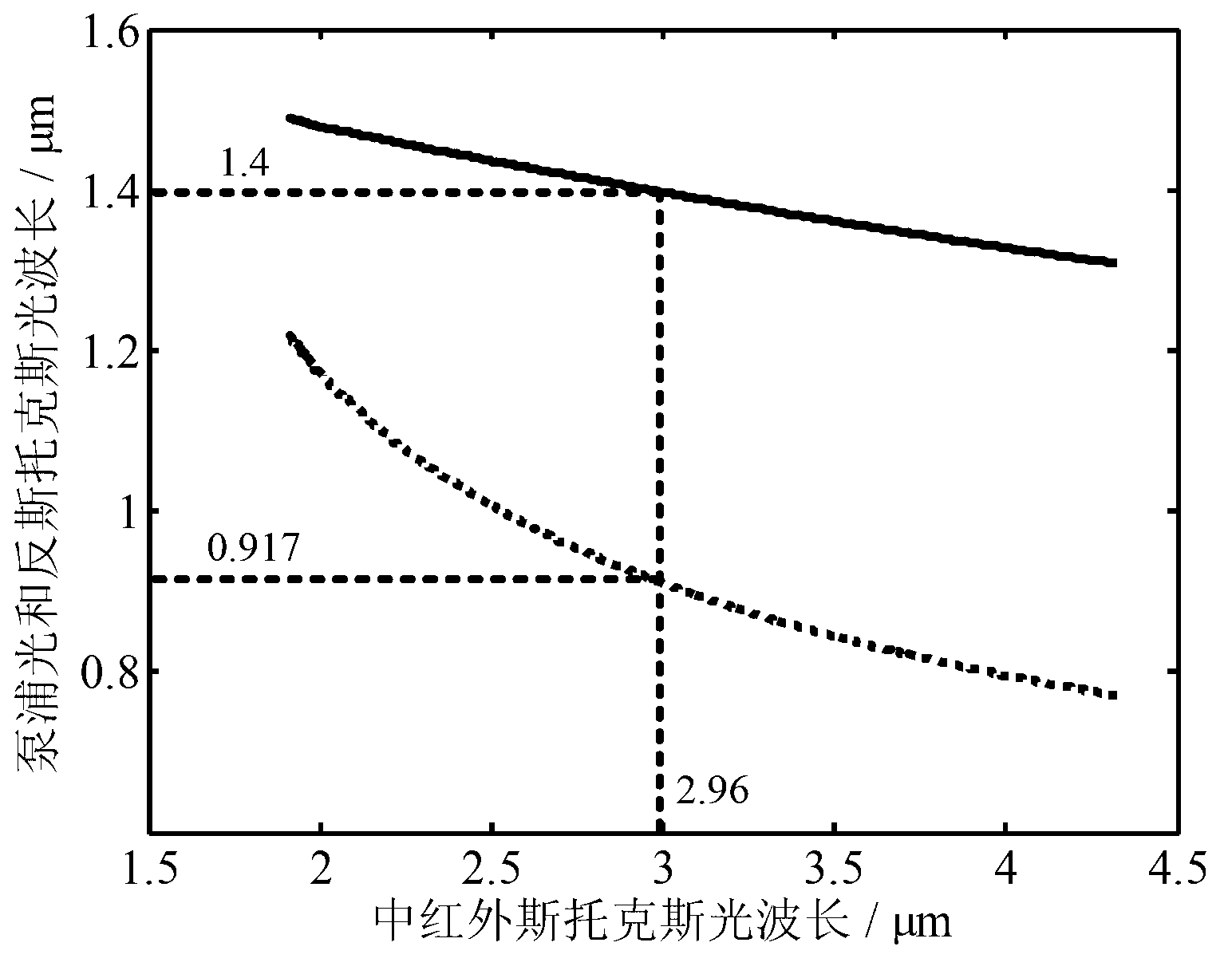

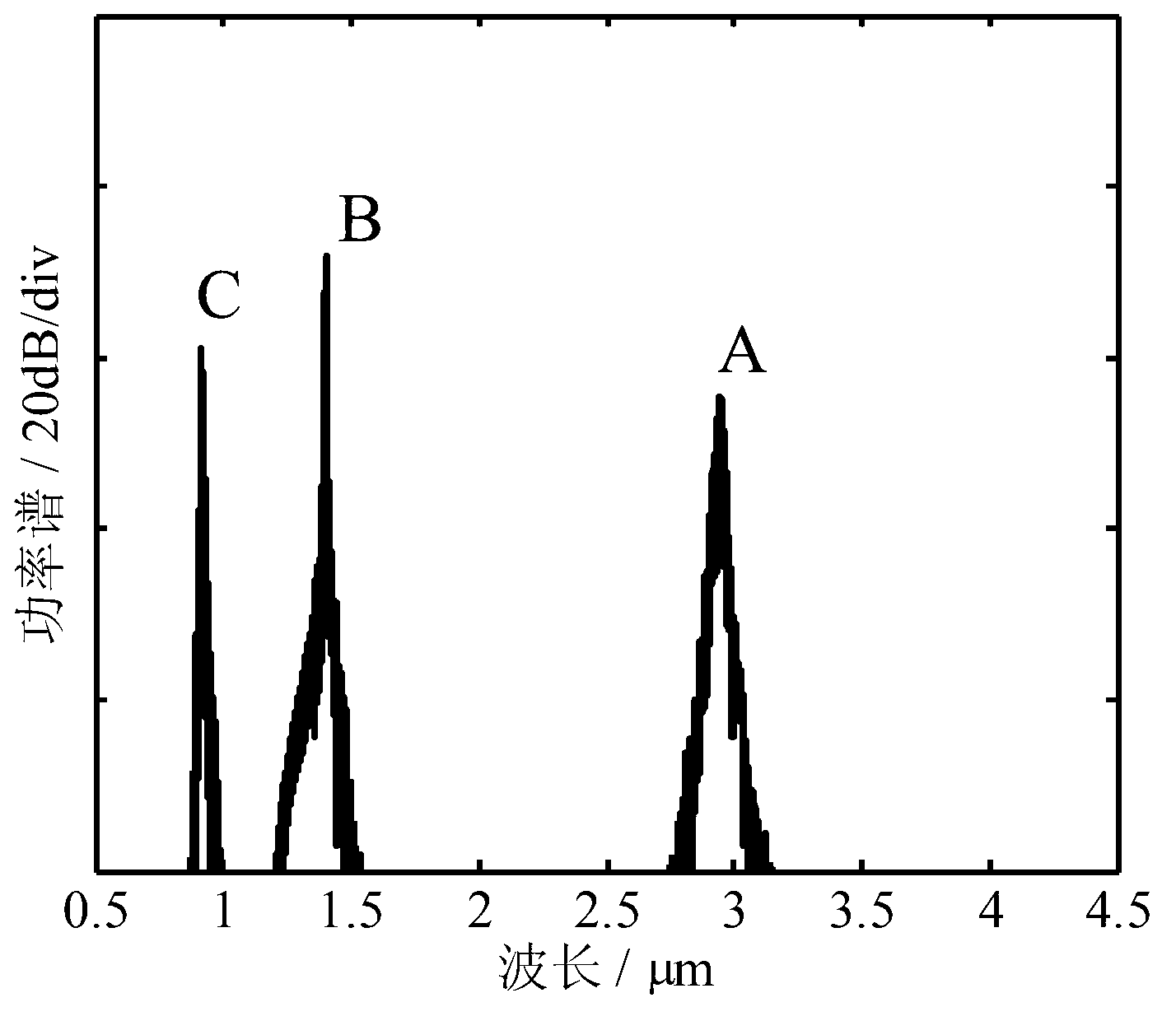

[0023] In this embodiment, the pump light with a wavelength of 1.4 μm generated by the pulsed fiber laser 1 and the signal light with a wavelength of 0.917 μm generated by the continuous fiber laser 2 are coupled to the mid-inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com