Method for synthesizing graphene with organic acid metal salt

A technology for synthesizing graphite and metal salts, applied in the direction of graphene, nano-carbon, etc., can solve the problems of increasing operating units and preparation costs, and not having advantages, and achieve the effects of easy control, excellent performance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

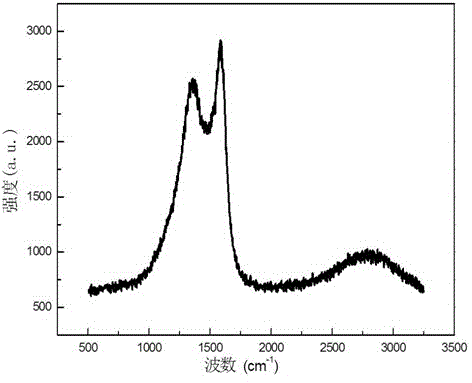

[0028] 2g of sodium acetate solid is placed in a porcelain boat, which is placed in the normal temperature zone of a horizontal tube furnace protected by a nitrogen atmosphere. After the tube furnace was heated to 700°C, the porcelain boat was pushed into the constant temperature zone and reacted for 120 minutes. After the product was cooled, the product was taken out, washed with deionized water, filtered, dried, and the product was collected. The XPS analysis results showed that the oxygen content was 10% (atomic percentage), and the scanning electron microscope results showed that the sample had a lamellar structure, and the thickness of the graphene-based sheet was ~4 nm.

Embodiment 2

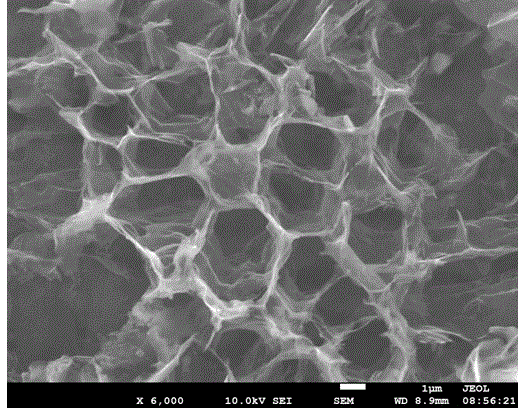

[0030] 2g of sodium acetate solid is placed in a porcelain boat, which is placed in the normal temperature zone of a horizontal tube furnace protected by a nitrogen atmosphere. After the tube furnace is heated to 1300°C, push the porcelain boat into the constant temperature zone and react for 0.5min. After the product was cooled, the product was taken out, washed with deionized water, filtered, dried, and the product was collected. XPS analysis results show that the oxygen content is 7% (atomic percentage), and scanning electron microscope results show that the sample has a network structure, and the thickness of the graphene-based sheet is ~2.2 nm

Embodiment 3

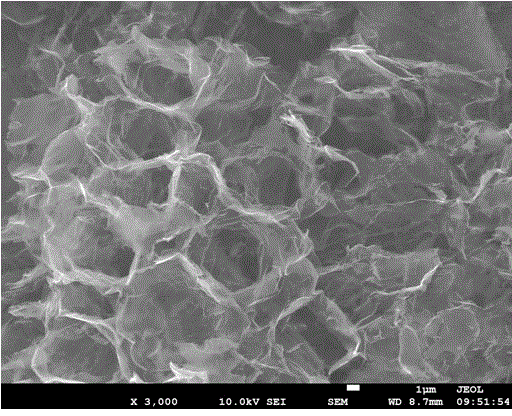

[0032] 1.5 g of potassium acetate solid was placed in a porcelain boat, which was placed in the normal temperature zone of a horizontal tube furnace protected by an argon atmosphere. After the tube furnace is heated to 1000°C, push the porcelain boat into the constant temperature zone and react for 2 minutes. After the product was cooled, the product was taken out, washed with deionized water, filtered, dried, and the product was collected. The XPS analysis results showed that the oxygen content was 7.0% (atomic percentage), and the scanning electron microscopy results showed that the sample had a network structure, and the thickness of the graphene-based sheet was ~4.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com