Method for producing functional fertilizers by comprehensive utilization of shrimp and crab shells

A shrimp and crab shell and functional technology, which is applied in the field of comprehensive utilization of shrimp and crab shells to produce functional fertilizers, can solve the problems of difficult treatment, environmental pollution, high energy and resource consumption, etc., to suppress crop diseases and improve plant immunity , the effect of exerting one's own vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Remove the meat and dirt from the fresh shrimp and crab shells, wash them and soak them in 10% dilute nitric acid. When the shrimp and crab shells are completely softened and there are no more bubbles, the pickling process is complete. Stir every 1 hour during the day for about 5 minutes. Minutes, then the shrimp and crab shells are taken out, washed with water, drained, and the soaked acid solution 1 is set aside;

[0079] Add the soaked shrimp and crab shells into 10% potassium hydroxide solution, boil for 2 hours while stirring, then filter, and the filtrate 2 is set aside;

[0080] The processed shrimp and crab shells are then put into a 40% KOH solution, heated to 100° C., stirred continuously, taken out and filtered after 3 hours, and the filtrate 3 is retained for use.

[0081] After filtering, the filtrate is stirred and dissolved with acid solution 1, filtered, and the insoluble matter is filtered out and then left to repeat the above steps together with fresh ...

Embodiment 2

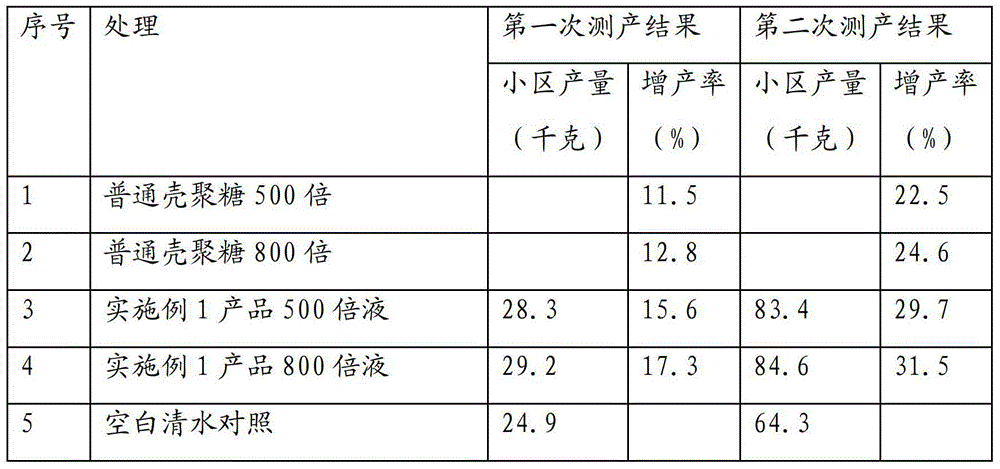

[0086] Example 2: Experiment on cucumbers

[0087] Adopt the common chitosan production method and the product prepared in this embodiment 1 to carry out comparative test simultaneously, from the cucumber seedling stage, interval 15 days, spray continuously 3 times, the results are shown in Table 1, the product prepared in embodiment 1 has great effect on increasing cucumber The yield has a significant effect, while prolonging the harvest period and improving the taste.

[0088] Table 1 Experimental results

[0089]

[0090] Conclusion: The application of the product of the present invention can increase the yield of cucumber by nearly 30%. After adopting the patented environmental protection process, in addition to chitosan, the content of calcium and small molecule polypeptide is increased, and the fertilizer efficiency is further improved.

Embodiment 3

[0092] Remove the meat and dirt from the fresh shrimp and crab shells, wash them and soak them in 8% dilute nitric acid. When the shrimp and crab shells are completely softened and there are no more bubbles, the pickling process is complete. Stir every 1 hour during the day for about 5 minutes. Minutes, then fish out the shrimp and crab shells and wash with water until neutral, drain, and soak the acid solution 1 for later use;

[0093] Add the soaked shrimp and crab shells into 8% potassium hydroxide solution, boil while stirring for 2 hours, then filter, and the filtrate 2 is set aside;

[0094] The processed shrimp and crab shells are then placed in a 45% KOH solution and heated to 110 0 C, keep stirring, take out and filter after 2 hours, and keep the filtrate 3 and the filtrate for use.

[0095] Stir and dissolve the filtered filtrate with acid solution 1, filter, and leave the insoluble matter filtered out and repeat the above steps together with fresh shrimp and crab s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com