Method for producing m-cresol

A technology for the production of m-cresol and m-cresol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high cost, cumbersome operation, and inability to obtain m-cresol, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

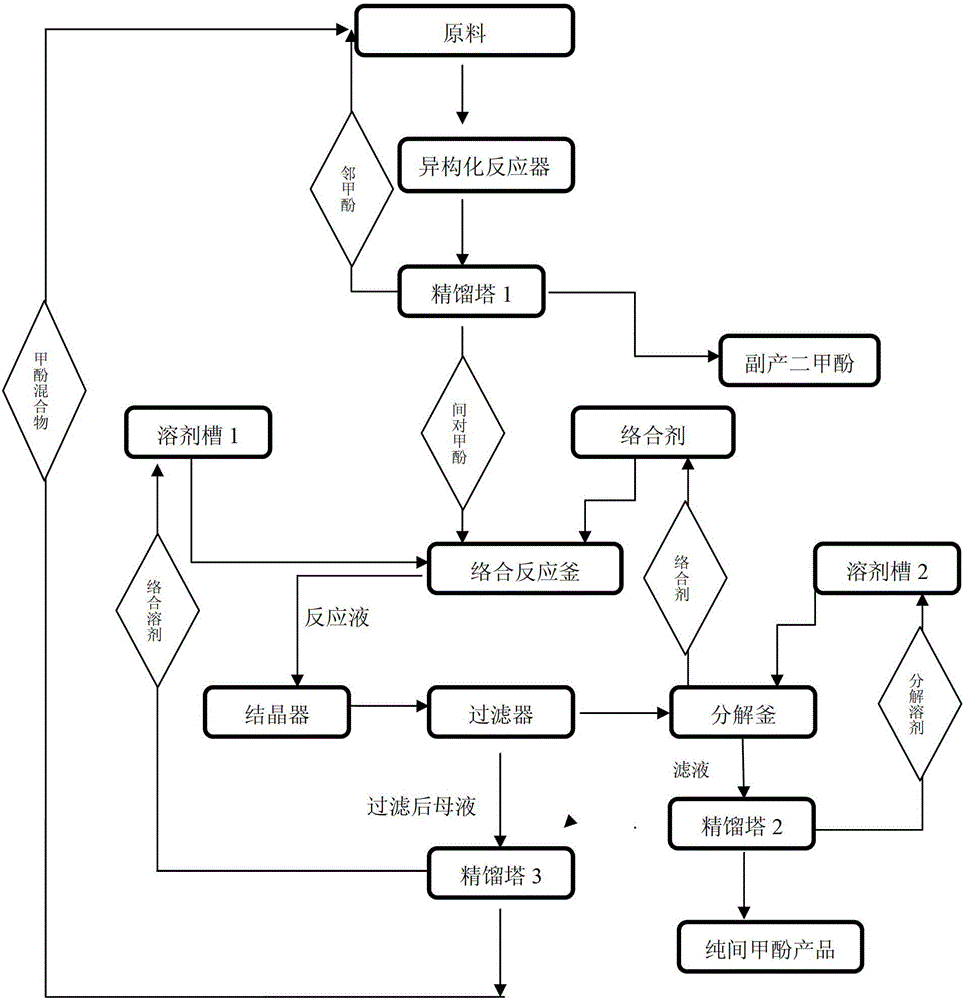

Image

Examples

Embodiment 1

[0049] Using industrial cresol as raw material, wherein the weight percentages of o-, m-, p-cresol and xylenol are respectively 24%, 42%, 28%, 6%, the isomerization reactor is a fixed-bed reactor, and the catalyst is Hydrogen type ZSM-5, the ratio of silicon to aluminum is 38, and the reaction space velocity is 0.4h -1 , the reaction temperature is 400°C, and the reaction pressure is 0.2Mpa. The reaction product is separated by rectification to obtain a mixture of xylenol product, o-cresol and m-p-cresol, and the separated o-cresol is returned to the fixed-bed reactor to carry out the isomerization reaction again.

[0050] Using urea as complexing agent, the molar ratio of its added amount to the m-cresol in the m-p-cresol mixture is 0.6:1, the complexation reaction temperature is 60°C, and the time is 2h. After the reaction is completed, slowly add petroleum ether with a boiling range of 60-90°C from the solvent tank 1, and the mass ratio of the amount of petroleum ether to ...

Embodiment 2

[0054] The experimental device and operation are the same as in Example 1, except that the isomerization catalyst is hydrogen type ZSM-5, and the silicon-aluminum ratio is 120. The experimental results are shown in Table 1.

Embodiment 3

[0056] The experimental device and operation are the same as in Example 1, except that the isomerization catalyst is mordenite. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com