Extraction method of E-viniferin

A technology of vinifolin and extraction method, which is applied in the field of viniferin extraction, and can solve problems such as research lag and low viniferin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

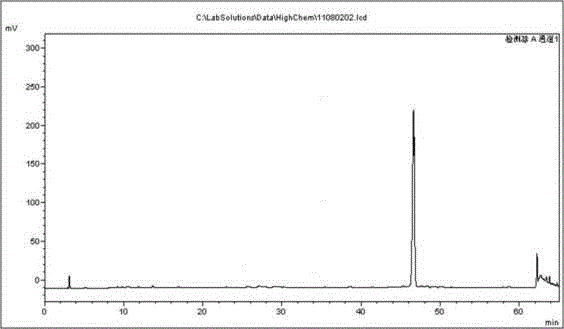

[0029] HPLC detection method of viniferin content:

[0030] Chromatographic column: C-18 250×4.6mm

[0031] Detection wavelength: 310nm

[0032] Flow rate: 1.0ml / min

[0033] Column temperature: 25°C

[0034] time (min) 0 5 15 18 29 35 57 57.1 61 61.1 65 65 B ratio (%) 20 30 30 37 37 50 50 100 100 20 20 stop

[0035] Mobile phase: A: 1% glacial acetic acid aqueous solution;

[0036] B: 1% methanol solution of glacial acetic acid.

Embodiment 2

[0038] (1) Extraction: add 2000g of water to 500g of grape seeds and soak at 95℃ under normal pressure for 5 times. Combine and let stand until the temperature is lower than 50°C, discard the precipitate, and obtain the supernatant;

[0039] (2) Adsorption and separation of macroporous resin: the extract from (1) is adsorbed by HP20 macroporous resin, and then gradiently eluted with water and ethanol aqueous solution with a concentration of 30%, 50%, 70%, and 95% by volume. / 2 column retention volume as a receiving volume, through thin-layer chromatography combined with analytical HPLC detection, collect components rich in vinifenin, combine them, at a temperature ≤ 60 ° C, a vacuum of 0.06 ~ 0.08 Concentrated under reduced pressure at MPa, the sugar content is 40Brix, the enrichment of Vinifenin;

[0040] (3) Separation of polyamide resin: the enrichment of vinifenin obtained after adsorption and separation of macroporous resin is dispersed into water (1:4) for separation of...

Embodiment 3

[0043] Steps (1) ~ (3) are the same as in Example 3;

[0044] (4) Toyopearl HW-40 column chromatography separation: Toyopearl HW-40 column chromatography was carried out on the components rich in vinifenin after separation by polyamide, and the volume percentage of water was 50%, 60%, 70%, 80% % methanol aqueous solution gradient elution, each 1 / 4 column retention volume is used as a receiving volume, through thin layer chromatography and other methods combined with analytical HPLC detection, with the pure product of vernifenin as the reference substance, collected rich in vinifenin Components, and concentrated under reduced pressure at a temperature of ≤60°C and a vacuum of 0.06-0.08MPa, with a sugar content of 10Brix, determined by the method of Example 1: the content of vinifenin was 81.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com