Method for producing fish protein and fish protein peptide

A protein and protein peptide technology, which is applied in the production of fish protein and fish protein peptide, can solve the problems of high energy consumption, low production capacity, and high cost, and achieve high product safety, low cost, and large production scale. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

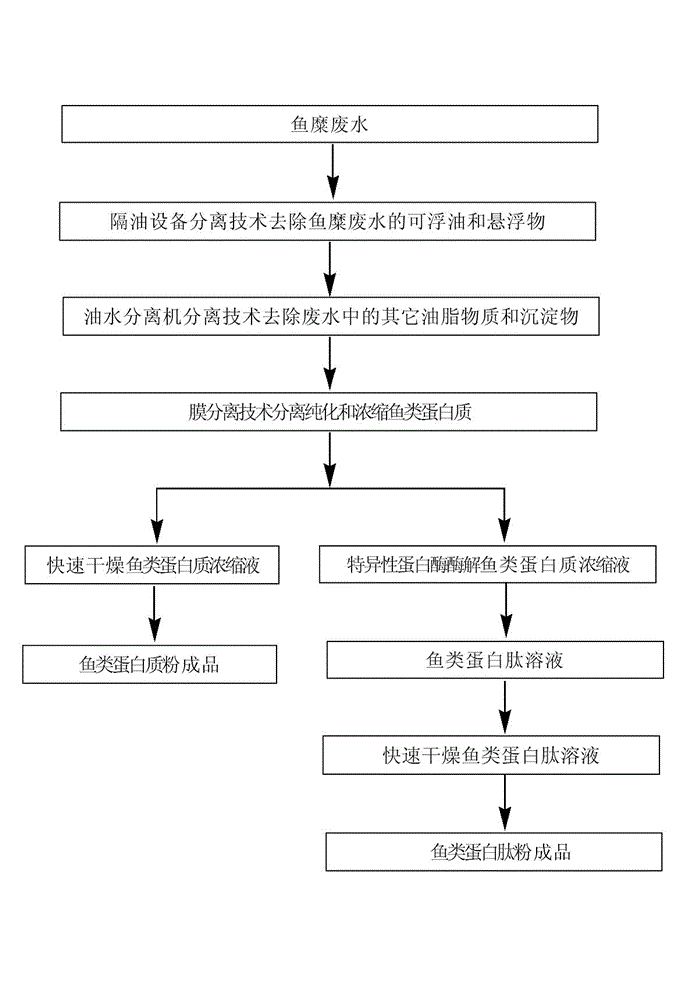

Image

Examples

Embodiment 1

[0039] 1. Take 1 tons of fish meal wastewater and use the oil -proof equipment with a treatment volume of 1 ton / hour to remove the floating oil and suspension in the wastewater.The oil -water separator with a speed of 7300R / min and a processing volume of 2 tons / hour removes other oil and sediments in the wastewater.

[0040] 2. Puritated vine -meal wastewater after the above methods, and use the nattial filter membrane with a relative molecular mass of 1kd to remove the purification of small molecular impurities, and condense into a concentrated solution with a mass percentage of 5%.

[0041] 3. Use spray to dry and dry quickly. The air outlet temperature is 90 ° C above the above concentrated liquid. The air inlet temperature is 180 ° C. The spray is dry and the spray is over. The finished fish protein powder is obtained.

[0042] 4. Put the fish protein concentrated liquid of the step 2 into the reactor. Use papaya protein enzymes to disintegrate. The enzymatic disintegration co...

Embodiment 2

[0045] 1. Take 10 tons of fish meal wastewater and use the oil -proof equipment with a treatment volume of 5 tons / hour to remove the floating oil and suspension in the wastewater.The oil -water separator with a speed of 4500R / min and the processing volume of 10 tons / hour removes other oil and sediments in the wastewater.

[0046] 2. Puritated vine -meal wastewater after the above methods, and use the nattial filter membrane with a relatively 3kd of nattial filter membrane to remove the small molecular impurities, and condense into a concentrated solution with a mass percentage of 20%.

[0047] 3. Use spray to dry and dry quickly. The air outlet temperature is 80 ° C above the above concentrated liquid. The air inlet temperature is 160 ° C. The spray is dry and the spray is completed.

[0048] 4. Put the fish protein concentrated liquid of step 2 into the reactor, use aspirinase enzymes, the enzyme disintegration conditions are: use sodium hydroxide and hydrochloric acid to adjust ...

Embodiment 3

[0051] 1. Take 10 tons of fish meal wastewater and use the oil -proof equipment with a treatment volume of 5 tons / hour to remove the floating oil and suspension in the wastewater.The oil -water separator with a speed of 6525R / min and a processing volume of 5 tons / hour removes other oils and sediments in the wastewater.

[0052] 2. Puritated vine -meal wastewater after the above methods, and use the nattial filter membrane with a relatively 5kd of the relative molecular mass to remove the small molecular impurities, and condense into a concentrated solution with a mass percentage of 10%.

[0053] 3. Use spray to dry and dry quickly. The air outlet temperature is 70 ° C above the above concentrated liquid. The air inlet temperature is 140 ° C. The spray is dry and the spray is over. The finished fish protein powder is obtained.

[0054] 4. Put the fish protein concentrated liquid of the step 2 into the reactor, use pineapple protein enzyme enzymes, the enzymatic disintegration condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com