Apparatus and method for preparing adiponitrile by electrolyzing acrylonitrile assisted by electro-active microbes

A technology of electroactive microorganisms and electrolysis of acrylonitrile, which is applied in the direction of electrolysis components, electrolysis process, electrolysis organic production, etc., can solve the problems of anode corrosion and high energy consumption, and achieve the effect of small anode corrosion, low energy consumption, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

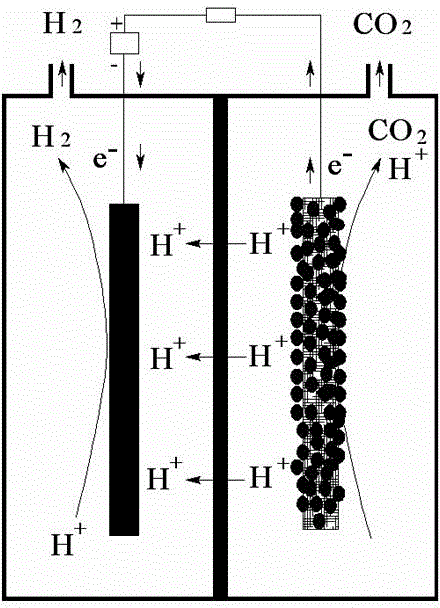

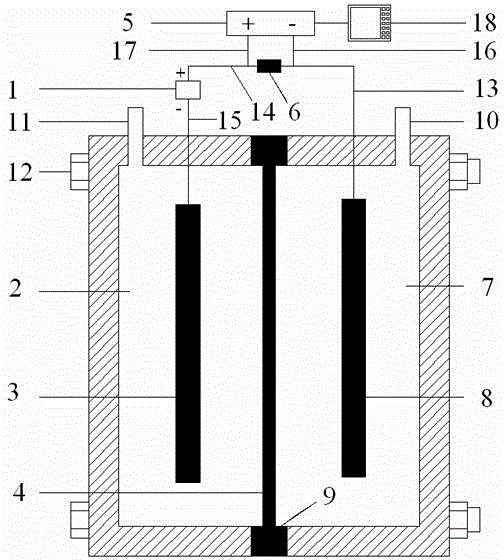

[0034] The Microbial Electrolysis Cell (MEC) used in the present invention is a device that uses microorganisms as catalysts to catalyze the oxidation of organic matter, and directly converts the chemical energy in the organic matter into hydrogen energy under an applied voltage.

[0035] like figure 1 As shown, the basic working principle of MEC: in the anaerobic environment, the microorganisms in the anode chamber of the MEC catalyze the oxidation of organic matter and generate electrons and H + ; The generated electrons are directly or indirectly transferred to the anode electrode, and then transferred to the cathode electrode through an external circuit under the action of an applied voltage, while protons migrate to the cathode through the proton exchange membrane; H + Combining with electrons produces hydrogen gas at the cathode. However, if the cathode electrode is a material with a high hydrogen evolution overpotential (such as Pb, Cr), and there is an aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com