Method for modification of lithium ion battery anode material

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of reducing the specific capacity of the material for the first discharge, the secondary sintering temperature has a great influence, and prolonging the production cycle of the product. The effect of improving cycle stability, improving high temperature storage performance, and environmental pollution-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

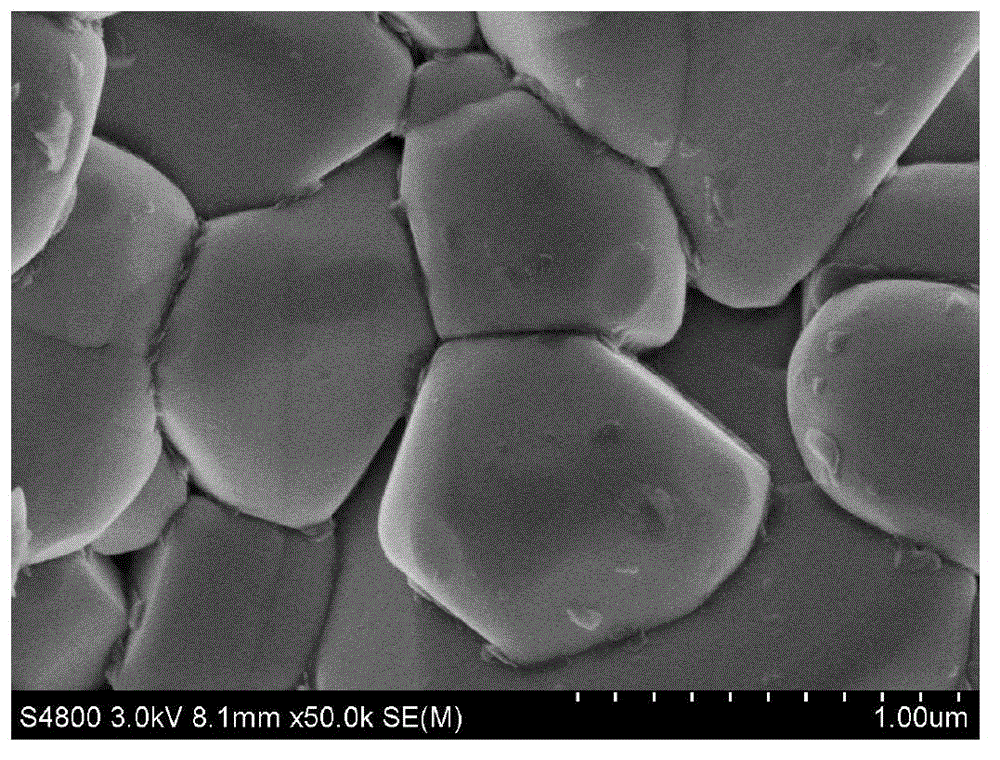

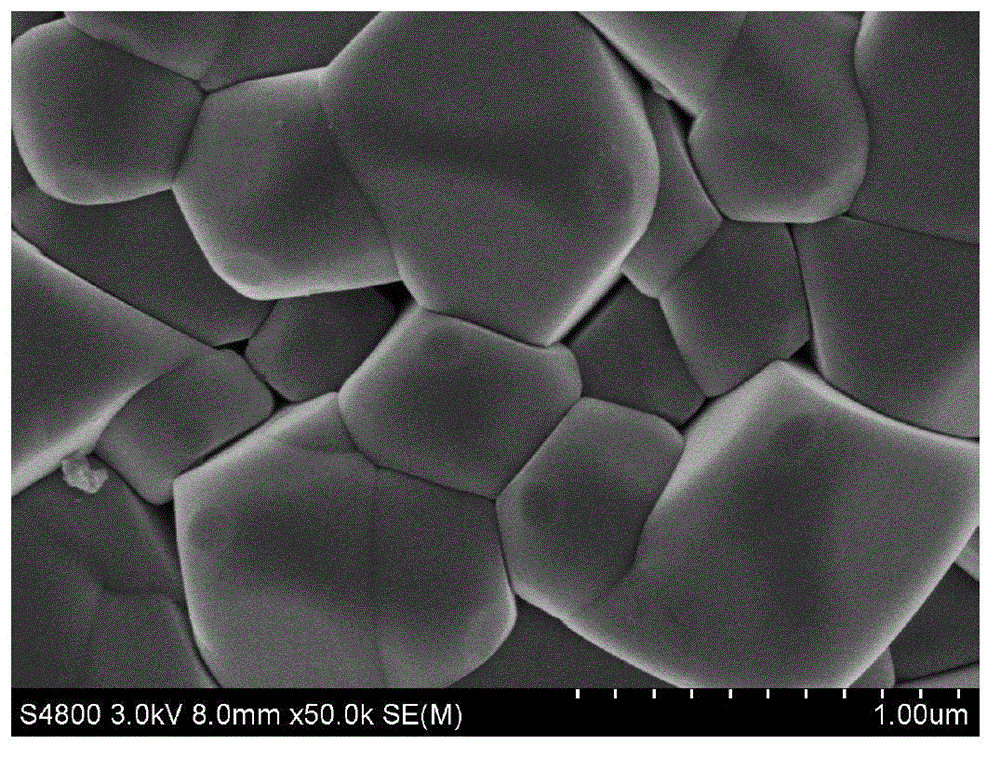

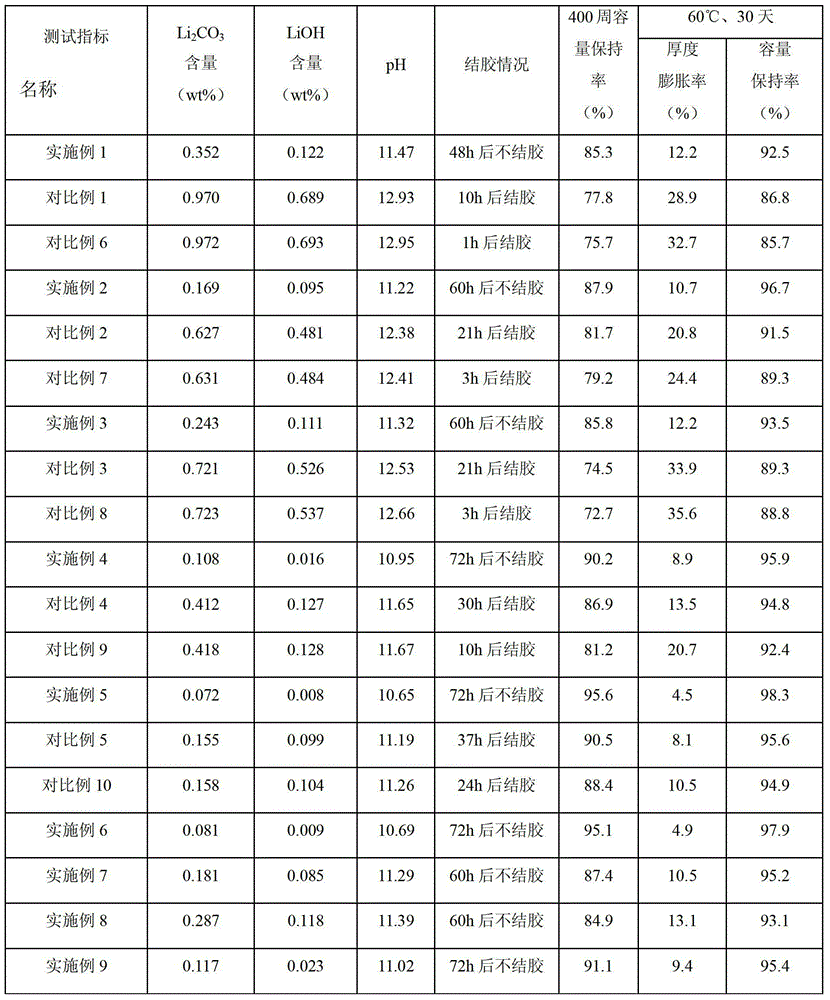

Embodiment 1

[0041] 950 g of ethanol and 50 g of formic acid were placed in a container and stirred and mixed, the rotational speed was controlled at 300 rpm, and the stirring time was 10 min to obtain a mixed organic solution. 1000g LiNi 0.8 co 0.2 o 2 Slowly add the positive electrode material into the above mixed organic solution, continue to stir, control the rotation speed to 100rpm, and stir for 120min to obtain a suspension; put the suspension in a centrifuge and centrifuge at a centrifugal speed of 6000rpm for 10min , and then washed with ethanol for 3 times, the washed material was transferred to a vacuum bench furnace, and dried at 80° C. to obtain a modified positive electrode material. At the same time of centrifugal separation, the waste liquid is transferred to the high-gravity bed equipment for rectification and separation of solvents. The purified and separated organic acids and alcohol solvents are stored in special containers for recycling and reuse.

Embodiment 2

[0043] 500 g of methanol and 500 g of acetic acid were placed in a container and stirred and mixed at a controlled speed of 400 rpm for 30 minutes to obtain a mixed organic solution. 2000g LiNi 0.8 co 0.1 mn 0.1 o 2 Slowly add the positive electrode material into the above mixed organic solution, continue to stir, control the rotation speed to 300rpm, and stir for 240min to obtain a suspension; put the suspension in a centrifuge and centrifuge at a centrifugal speed of 5000rpm for 15min , and then washed with methanol for 5 times, the washed material was transferred to a vacuum bench furnace, dried at 40° C., sieved and classified to obtain a modified positive electrode material. At the same time of centrifugal separation, the waste liquid is transferred to the high-gravity bed equipment for rectification and separation of solvents. The purified and separated organic acids and alcohol solvents are stored in special containers for recycling and reuse.

Embodiment 3

[0045] 800 g of ethanol and 200 g of isopropionic acid were placed in a container and stirred and mixed at a controlled speed of 100 rpm for 10 minutes to obtain a mixed organic solution. 250g LiNi 0.8 co 0.15 Al 0.05 o 2 Slowly add the positive electrode material into the above mixed organic solution, continue to stir, control the rotation speed to 400rpm, and take 30min to obtain a suspension; place the suspension in a centrifuge and centrifuge at a centrifugal speed of 8000rpm for 5min, then Washed with ethanol for 8 times, the washed material was transferred to a vacuum bench furnace, dried at 90°C, screened and classified to obtain a modified positive electrode material. At the same time of centrifugal separation, the waste liquid is transferred to the high-gravity bed equipment for rectification and separation of solvents. The purified and separated organic acids and alcohol solvents are stored in special containers for recycling and reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com